Are you a master crafter or a DIY daredevil looking to venture into the realm of aluminum and metal fusion? Whether you’re fixing up a trusty tool or crafting a one-of-a-kind masterpiece, the challenge of gluing aluminum to metal may seem like an enigma wrapped in perplexity. But fret not. In this blog post, we’ll unravel the secrets behind this art form, arming you with indispensable tips and insights to achieve adhesive triumph.

Before we embark on this sticky journey, let’s address the jumbo-sized elephant in the workshop: Can you truly glue aluminum to metal? The answer is an emphatic yes. However, it necessitates careful consideration of materials and adhesives, as well as a profound understanding of the bonding process.

To conquer the task at hand, gather your arsenal of essentials. First and foremost, arm yourself with a reliable adhesive that suits your specific metallic concoction. Epoxy adhesives reign supreme in the realm of aluminum-to-metal bonding due to their unrivaled adhesion properties.

But here’s where things get interesting: Surface preparation holds the key to triumph. Regardless of which adhesive tickles your fancy – be it epoxy, polyurethane, or cyanoacrylate (aka super glue) – meticulous cleansing is paramount. Bid farewell to dirt, grease, and oxidation by employing an appropriate cleaner or solvent. And for that extra oomph in adhesion prowess, consider giving those surfaces a gentle sanding or roughening.

However, brace yourself for potential hurdles along this sticky path. Aluminum’s smooth and nonporous surface poses quite the challenge for any adhesive attempting to penetrate its fortress-like exterior. Fear not; salvation lies in selecting an adhesive boasting Herculean adhesive strength and elasticity.

Moreover, keep an eye out for external factors that may influence adhesive performance. Temperature, humidity, and the specific types of aluminum and metal can all play a role in this sticky saga. So, channel your inner Sherlock Holmes and meticulously follow the manufacturer’s instructions to ensure that your chosen adhesive is tailor-made for your project’s demands.

In the upcoming chapters of this guide, we’ll plunge headfirst into the preparation process, adhesive selection, and application techniques. By the time we bid adieu, you’ll be armed with a treasure trove of knowledge to conquer any aluminum-to-metal bonding endeavor that comes your way.

Properties of Aluminum and Metal: What to Consider

Contents

- 1 Properties of Aluminum and Metal: What to Consider

- 2 The Challenge of the Oxide Layer on Aluminum

- 2.1 The Oxide Layer: Friend or Foe?

- 2.2 Surface Preparation Techniques: Unleashing Aluminum’s True Potential

- 2.3 Adhesive Compatibility: A Perfect Match

- 2.4 Temperature Resistance: Conquering Extreme Conditions

- 2.5 Strength Requirements: Adhering to Demands

- 2.6 Taming the Oxide Layer: A Journey to Success

- 3 Proper Surface Preparation for Glue Adhesion

- 4 Types of Adhesives Suitable for Bonding Aluminum and Metal

- 5 Epoxy Adhesive: Benefits and Limitations

- 6 Cyanoacrylate Adhesive: Benefits and Limitations

- 7 Structural Acrylic Adhesive: Benefits and Limitations

- 8 Conclusion

Aluminum, with its lightweight nature and corrosion resistance, is a remarkable metal. When it comes to gluing aluminum to other metals, several factors must be considered to ensure a strong and durable bond. In this blog post, we will explore the properties that should be taken into account when gluing aluminum to metal, empowering you to make informed choices for your projects.

Surface Preparation: Clean and Smooth

To achieve a strong bond, both the aluminum and metal surfaces must be clean, smooth, and free from contaminants like oil or dirt. Enhancing adhesion can be accomplished through techniques such as sanding or roughening the surfaces.

Compatibility between Adhesive and Metals

The selection of the right adhesive is crucial for successful bonding. Not all adhesives work well with all metals, so it is essential to choose one that is compatible with both aluminum and the metal being used.

Temperature and Environmental Conditions

Consider the adhesive’s temperature resistance. As aluminum has a low melting point, it is vital to choose an adhesive that can withstand high temperatures without compromising its bonding strength. If your project will face extreme temperatures or harsh environmental conditions, opt for an adhesive resistant to these factors.

Strength Requirements

Different applications require different levels of strength. It is important to select an adhesive that provides the necessary strength and durability for your specific project. Keep in mind that not all adhesives are suitable for high-stress applications.

Removing the Oxide Layer

Aluminum naturally forms an oxide layer on its surface, hindering adhesion. Surface preparation techniques like sanding, abrasion, or chemical treatment can remove or modify this oxide layer before applying adhesive, ensuring better bonding results.

Conclusion:

When gluing aluminum to metal, it is crucial to consider factors such as surface preparation, adhesive compatibility, temperature resistance, strength requirements, and the removal of the oxide layer.

The Challenge of the Oxide Layer on Aluminum

Today, we embark on an exhilarating journey into the realm of adhesion, where we unravel the complexities and triumphs of conquering the formidable oxide layer on aluminum. Join us as we unlock the secrets to achieving robust and enduring bonds between aluminum and other metals.

The Oxide Layer: Friend or Foe?

The oxide layer on aluminum serves as a shield against corrosion, protecting this versatile metal. However, this very layer poses a challenge when it comes to adhesive bonding. Understanding the purpose of the oxide layer and its impact on bonding is crucial in overcoming this obstacle and achieving successful adhesion.

Surface Preparation Techniques: Unleashing Aluminum’s True Potential

To overcome the oxide layer’s resistance to bonding, surface preparation techniques come to the rescue. Mechanical abrasion techniques, such as sanding and scrubbing, strip away the oxide layer, laying bare the aluminum surface for optimal bonding. Chemical treatments, such as etching with phosphoric acid or chromic acid, dissolve or modify the oxide layer, creating a receptive surface for adhesion. Caution must be exercised when handling chemicals, ensuring safety measures are followed.

Adhesive Compatibility: A Perfect Match

Choosing adhesives specifically designed for bonding aluminum is paramount in achieving successful adhesion. Specialized primers play a pivotal role by modifying the surface properties of the oxide layer, enhancing adhesion at a molecular level. These ingenious formulations create a bond that surpasses conventional expectations, resulting in stronger and more durable bonds.

Temperature Resistance: Conquering Extreme Conditions

Considering temperature variations is crucial when selecting adhesives for aluminum bonding. High-temperature adhesives ensure bond integrity even in extreme conditions. These remarkable formulations exhibit compatibility with both aluminum and other metals, enabling reliable bonding under challenging circumstances.

Strength Requirements: Adhering to Demands

Different applications require varying load-bearing capabilities. Assessing the specific strength requirements allows for informed adhesive selection. Adhesives boasting appropriate tensile and shear strength are vital in ensuring the longevity and reliability of bonded assemblies. Thorough testing guarantees suitability for each unique project.

Taming the Oxide Layer: A Journey to Success

By diligently following proper surface preparation techniques, selecting compatible adhesives, considering temperature resistance, and evaluating strength requirements, we conquer the challenges posed by the oxide layer on aluminum. Adherence to manufacturer guidelines, accompanied by rigorous testing and evaluation, paves the way for optimal results.

Proper Surface Preparation for Glue Adhesion

Prepare to embark on a journey into the realm of glue adhesion as we explore the critical importance of proper surface preparation when bonding aluminum to other metals. Grab your safety goggles and get ready to dive deep into this essential topic.

Cleanliness is Key:

Before embarking on any gluing adventure, cleanliness should be your top priority. Contaminants such as dirt, grease, and oil can seriously impede the adhesive’s ability to form a strong bond. So, give those surfaces a gentle scrub with a mild detergent or solvent, ensuring they are squeaky clean and dry before proceeding.

The Power of Roughened Surfaces:

Smooth aluminum and other metals may not provide the most conducive bonding conditions. That’s where roughening or etching comes into play. By creating microscopic irregularities on the surfaces, we increase the contact area available for bonding and enhance adhesion. Think of it as creating a cozy nest for your adhesive to snuggle into.

Sanding for Success:

In some cases, sanding with fine-grit sandpaper can work wonders when bonding aluminum to stainless steel or other metals. This process generates a roughened texture on the metal surface, enabling mechanical interlocking between the adhesive and the metals. It’s like giving your adhesive a firm handshake with its new metal friend.

Chemical Etching: A Magical Touch:

For more stubborn metals, chemical etching might be necessary to achieve optimal surface preparation. This technique involves using an acidic solution or chemical treatment to remove oxide layers or coatings on the metal surfaces. The result? A fresh metal surface that eagerly awaits its adhesive companion.

Modern Marvels:

Not all adhesives require extensive surface preparation when gluing aluminum to metal. Some innovative formulations are specifically designed for bonding difficult-to-bond materials like aluminum without the need for roughening or etching. These adhesives often come with special primers or surface activation agents, making the bonding process a breeze.

Types of Adhesives Suitable for Bonding Aluminum and Metal

When it comes to bonding aluminum and metal surfaces, selecting the right adhesive is essential for a successful project. With a wide range of options available, it can be overwhelming to choose the perfect glue. In this article, we will explore the different types of adhesives suitable for bonding aluminum and metal surfaces, ensuring that you make an informed decision for your DIY or repair job.

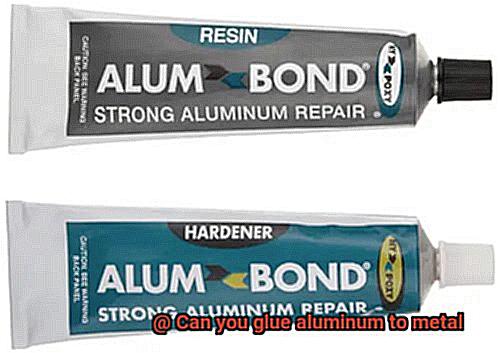

Epoxy Adhesives: The Powerhouses

Epoxy adhesives are the superheroes of bonding aluminum and metal. These two-component adhesives consist of a resin and a hardener that create a chemical reaction when mixed, resulting in a strong and durable bond. Epoxy adhesives can withstand extreme temperatures and harsh environments, making them ideal for demanding applications where strength and durability are crucial.

Cyanoacrylate Adhesives: The Speed Demons

For instant bonding, cyanoacrylate adhesives, also known as super glue, are the go-to option. These fast-acting adhesives work wonders on smooth and clean metal surfaces, providing a strong bond in no time. However, they may not be as effective on rough or porous metal surfaces, so proper surface preparation is important.

Structural Acrylic Adhesives: The Versatile Solution

When both strength and flexibility are required, structural acrylic adhesives come to the rescue. These adhesives cure quickly and offer high bond strength, making them perfect for load-bearing applications. They also exhibit excellent resistance to chemicals, UV radiation, and temperature fluctuations, ensuring a reliable bond in various environments.

Silicone Adhesives: The Flexible Allies

For flexibility in your bond, silicone adhesives are the way to go. They can accommodate the expansion and contraction of metal surfaces caused by temperature changes, ensuring a long-lasting bond. Silicone adhesives also provide excellent resistance to moisture and chemicals, making them ideal for outdoor or wet environments.

Choosing the Right Adhesive: Key Considerations

Selecting the perfect adhesive for bonding aluminum and metal requires considering several factors. The type of metal, surface preparation, temperature range, and expected load should all be taken into account. It is recommended to consult adhesive manufacturers or experts who can guide you in selecting the most suitable adhesive for your specific needs.

Epoxy Adhesive: Benefits and Limitations

In the world of adhesives, epoxy adhesive emerges as a superhero when it comes to bonding aluminum to other metals. With its high strength, durability, resistance to environmental factors, and gap-filling properties, epoxy adhesive is a reliable choice. But like any superhero, epoxy adhesive also has its limitations. In this blog post, we will explore the advantages and disadvantages of using epoxy adhesive for metal-to-metal bonding applications.

Advantages of Epoxy Adhesive:

- Super Strength and Durability: Epoxy adhesives are renowned for their excellent bonding capabilities, especially for metal-to-metal applications. When properly applied and cured, they form a strong and long-lasting bond that can handle substantial stress and load.

- Resistance to Environmental Assaults: Epoxy adhesives fearlessly withstand heat, chemicals, moisture, and UV radiation. This makes them suitable for both indoor and outdoor applications. When used to bond aluminum to other metals, epoxy adhesive shields against corrosion and degradation caused by harsh environmental conditions.

- The Filler of Gaps: Epoxy adhesive swoops in to fill small gaps or irregularities between the surfaces being bonded, ensuring a tight and secure connection. This is crucial when gluing aluminum to other metals since even the slightest variations in surface contours need to be filled for a strong bond.

Limitations of Epoxy Adhesive:

- The Waiting Game: One limitation of epoxy adhesive is its relatively long curing time. Depending on the specific product and application, it can take several hours or even days to fully cure and reach maximum strength. This may not be ideal for situations that require speedy assembly or quick repairs.

- Surface Prep Challenges: Certain metals or surfaces may require special preparation techniques to ensure proper adhesion. For example, stainless steel or galvanized steel may need sanding or etching before applying epoxy adhesive. Coatings or finishes on metal surfaces might also need removal or modification. Carefully following the manufacturer’s instructions is vital for successful bonding.

Cyanoacrylate Adhesive: Benefits and Limitations

When it comes to joining aluminum to metal, cyanoacrylate adhesive, or super glue, emerges as a compelling option due to its remarkable bonding properties and versatility. However, it’s vital to delve into the benefits and limitations of using this adhesive for such applications. In this blog post, we will explore the advantages and disadvantages of cyanoacrylate adhesive in the context of bonding aluminum and metal surfaces.

Advantages of Cyanoacrylate Adhesive:

- Instant Bonding: Cyanoacrylate adhesive boasts the remarkable ability to form an instant bond upon contact with the surfaces to be joined. This ensures a swift and efficient bonding process, saving valuable time and boosting overall productivity.

- Strong and Reliable Bond: With cyanoacrylate adhesive, you can achieve a tight and secure connection between aluminum and metal surfaces. This results in a strong and reliable bond that is particularly advantageous for applications that demand durability and long-lasting adhesion.

- Versatility: The versatility of cyanoacrylate adhesive is a significant advantage as it can be used on an extensive range of materials, including metals, plastics, ceramics, and select rubber compounds. This flexibility makes it a convenient choice for various bonding applications where different materials need to be seamlessly joined together.

- Temperature and Moisture Resistance: Another notable benefit of cyanoacrylate adhesive is its exceptional resistance to temperature and moisture. It can withstand high temperatures without compromising its bond strength, making it suitable for applications exposed to heat or thermal cycling. Additionally, its resistance to water and moisture renders it ideal for outdoor or humid environments.

Limitations of Cyanoacrylate Adhesive:

- Surface Sensitivity: Certain metals, such as stainless steel or aluminum alloys, may necessitate surface preparation before applying cyanoacrylate adhesive to ensure optimal bonding. This process involves thorough cleaning and roughening of the surfaces to enhance adhesion.

- Inability to Fill Gaps and Bond Uneven Surfaces: Cyanoacrylate adhesive exhibits its best performance when the surfaces to be joined are smooth and fit closely together. It may not effectively fill gaps or bond uneven surfaces, which can pose limitations in specific applications.

- Brittle Over Time: Over the course of time, cyanoacrylate adhesive can become brittle, lacking the flexibility required for applications that involve frequent movement or vibration. In such cases, it is crucial to consider using adhesives specifically designed for flexible bonding or exploring alternative methods like mechanical fastening.

Structural Acrylic Adhesive: Benefits and Limitations

Structural acrylic adhesive is a remarkable bonding solution that possesses both impressive benefits and certain limitations. Let’s delve into the world of this adhesive wonder and explore its superpowers and kryptonite when it comes to bonding aluminum to metal.

First and foremost, the strength and durability of structural acrylic adhesive are truly extraordinary. It’s like the Hulk of adhesives, capable of withstanding heavy loads and tough conditions. When you need a bond that can handle serious weight, structural acrylic adhesive is your go-to.

But wait, there’s more. This adhesive is as versatile as a Swiss Army knife. Not only can it bond aluminum, but it can also form strong bonds with a wide range of metals including stainless steel, copper, and even titanium. It’s like having a superhero who can team up with any material to save the day.

Speaking of saving the day, structural acrylic adhesive is resistant to the forces of nature. It can withstand moisture, chemicals, and temperature fluctuations like a true champion. So whether your application faces harsh conditions or braves the great outdoors, this adhesive will stand strong against the elements.

Time is of the essence, right? Well, good news. Structural acrylic adhesive has a fast curing time compared to other adhesives. It’s like having the Flash on your side – it gets the job done quickly and efficiently. This means you can speed up your assembly or production processes and increase overall productivity. Who doesn’t love saving time?

Now let’s talk about the limitations of structural acrylic adhesive. Like any superhero, it has its weaknesses. One of them is its relatively higher cost compared to other types of adhesives. Hey, being a superhero comes at a price.

Another limitation is the need for proper surface preparation before applying the adhesive. This means you have to clean, dry, and remove any contaminants or oxidation from the bonding surfaces. It’s like giving your adhesive a clean canvas to work its magic. But hey, preparation is key for a strong bond, right?

Lastly, structural acrylic adhesive may not be suitable for applications that require high flexibility or impact resistance. It’s like Superman without his cape – it’s strong, but it may struggle with extreme flexing or sudden impacts. So if your application involves a lot of movement or vibration, you might want to consider alternative options.

hzYj6-TITsc” >

Also Read: How to Glue Aluminum to MDF?

Conclusion

In conclusion, the answer to the question “Can you glue aluminum to metal?” is a resounding yes. The combination of aluminum and other metals can be successfully bonded using various adhesive options available in the market. From epoxy adhesives to cyanoacrylate glues, there are plenty of choices for achieving a strong and durable bond between these materials.

The key to successfully gluing aluminum to metal lies in proper surface preparation. Before applying any adhesive, it is crucial to clean and degrease both surfaces thoroughly. This step ensures that no contaminants or oils interfere with the bonding process, allowing the adhesive to adhere effectively.

Once the surfaces are cleaned, selecting the right adhesive becomes essential. Epoxy adhesives are commonly used for bonding aluminum to metal due to their excellent strength and durability. These adhesives create a strong chemical bond between the two materials, providing long-lasting results.

Another option is cyanoacrylate glue, also known as super glue. This type of adhesive works well for smaller projects or when a quick fix is needed. Cyanoacrylate glues bond rapidly and can provide a reliable connection between aluminum and metal surfaces.

It is important to note that not all adhesives work equally well on aluminum and different metals. Therefore, it is recommended to consult product specifications or seek professional advice when choosing an adhesive for your specific application.

In summary, gluing aluminum to metal is indeed possible with the right adhesive and proper surface preparation. By following these guidelines and selecting an appropriate glue, you can achieve a secure bond that withstands various environmental conditions and provides lasting results.