Do you have a pile of broken metal objects lying around? Sick of dealing with the frustration and expense of replacing them? Well, I’ve got some good news for you. Krazy Glue, that trusty adhesive we all know and love, might just be the answer to your metal-bonding troubles. In this blog post, we’re going to dive into the nitty-gritty of whether Krazy Glue can hold metal together. We’ll talk about its strengths, weaknesses, and give you some tips and tricks to ensure success.

Let’s start with the basics. Krazy Glue is a cyanoacrylate adhesive, or as we like to call it, super glue. And let me tell you, this stuff lives up to its name when it comes to bonding metal. It’s got a powerful bonding agent that creates an insanely strong bond once it touches those metal surfaces. So whether you’re fixing up some jewelry or attaching hardware, Krazy Glue is up for the challenge.

One thing that sets Krazy Glue apart from other adhesives is its lightning-fast drying time. Seriously, this stuff dries in seconds. No more waiting around for hours on end. You can get back to your project in no time flat. And here’s another bonus: Krazy Glue is resistant to moisture. That means it won’t let you down even in humid or wet environments.

Now, before you go running off to glue everything in sight, there are a couple of things you should keep in mind. While Krazy Glue works wonders on small metal pieces, it might not be your best bet for heavy-duty applications or load-bearing situations. And here’s a word of caution: once you apply Krazy Glue to your metal surfaces, there’s no turning back. It forms an unbreakable bond that could damage your precious metals if forcefully separated.

But fear not. I’ve got some tips and tricks to help you get the most out of your Krazy Glue experience. First things first, make sure your metal surfaces are squeaky clean.

Give ’em a good wipe down with alcohol or acetone to remove any dirt or oils that could mess with the bond. Then, apply a thin layer of glue to both surfaces and press them together firmly for a few seconds.

And if you’re working on a bigger project or something with intricate designs, consider reinforcing the joint with screws or wire.

What is Krazy Glue?

Contents

- 1 What is Krazy Glue?

- 2 What Types of Metals Can Krazy Glue Bond?

- 3 What Surface Preparation is Required for Using Krazy Glue on Metal?

- 4 How to Apply Krazy Glue to Metal?

- 5 Does Krazy Glue Work on All Types of Metals?

- 6 Is Krazy Glue Suitable for Load-Bearing or High-Stress Applications?

- 7 Factors to Consider When Using Krazy Glue on Metal

- 8 Alternatives to Krazy Glue for Bonding Metal

- 9 Conclusion

When it comes to bonding metal, finding the perfect adhesive can be a challenge. You need something that is strong, reliable, and quick-drying to ensure your metal pieces stay securely in place. Look no further than Krazy Glue – the ultimate bonding solution. In this article, we will delve into the features and benefits of Krazy Glue for metal applications, as well as provide tips for achieving optimal results.

Lightning-Fast Drying Time:

Krazy Glue’s standout feature is its lightning-fast drying time. Within seconds of application, this adhesive sets, allowing you to move forward with your project without any delays. Gone are the days of waiting for glue to dry or using clamps to hold your metal pieces together – Krazy Glue gets the job done instantly.

Unparalleled Versatility:

Krazy Glue isn’t limited to just metal bonding; it is a versatile adhesive that works on a wide range of materials. Whether you’re working with plastic, ceramics, rubber, or even some types of wood, Krazy Glue has got you covered. This versatility makes it the go-to choice for all your DIY projects and repairs.

Formidable Strength and Durability:

When it comes to holding power, Krazy Glue never disappoints. It forms a bond that can withstand impacts, vibrations, and other external forces. However, it’s important to note that the strength of the bond may vary depending on factors such as the type of metal being bonded and the surface area. For load-bearing or high-stress applications, consider using specialized epoxies or adhesives.

Surface Preparation for Optimal Results:

To achieve the best results with Krazy Glue on metal surfaces, proper preparation is key. Ensure that the metal is clean, dry, and free from any oils, dirt, or rust that may interfere with the bonding process. For enhanced adhesion between the glue and the metal, roughening the surface with sandpaper is recommended.

Considerations for Specialized Metals:

While Krazy Glue can hold certain types of metal together, it may not be suitable for all applications. Factors such as temperature, humidity, and the specific properties of the metal being bonded should be taken into account. Specialized metals like stainless steel or titanium may require the use of specialized epoxy or adhesive.

What Types of Metals Can Krazy Glue Bond?

In this article, we will explore the secrets behind this powerful adhesive and its ability to create strong bonds between different types of metals. Get ready to unlock the potential of Krazy Glue as we dive into the nitty-gritty details.

Smooth vs. Porous Metals: Unleashing the Power of Texture

When it comes to bonding metals, surface characteristics hold the key. Smooth metals like stainless steel and aluminum can pose a challenge for Krazy Glue. With their low surface energy, these metals make it difficult for the adhesive to establish a reliable bond. But fret not. There’s a simple trick to achieve success – roughen the surface with sandpaper or a file before applying the glue. This creates tiny grooves that enhance adhesion, allowing Krazy Glue to work its magic.

On the other hand, porous metals like copper and brass are a match made in adhesive heaven. Their textured surfaces provide microscopic gaps for the glue to seep into, creating a stronger bond. Just ensure that the metal surface is clean and free from contaminants that could hinder adhesion, and you’re good to go.

Temperature Resistance: Conquering Extremes

Krazy Glue is renowned for its ability to withstand a wide range of temperatures once fully cured. However, extreme temperature fluctuations can challenge its effectiveness on certain metals.

In such cases, it is wise to turn to specialized high-temperature adhesives specifically designed for metal bonding. These adhesives are formulated to conquer temperature extremes, ensuring your metal bonds remain intact even under the harshest conditions.

Choosing the Right Formulation: Tailoring Adhesion to Perfection

Did you know that Krazy Glue offers different formulations for specific purposes? Some variants are specially designed for bonding metal surfaces, offering superior results compared to general-purpose glue. These specialized formulations possess enhanced adhesion properties and can withstand higher temperatures. By choosing the right formulation, you can tailor the adhesive to your specific metal bonding needs, ensuring optimal performance and durability.

Surface Preparation: The Gateway to Seamless Bonds

To achieve the strongest bond possible, proper surface preparation is crucial. Thoroughly clean the metal surface to remove any dirt, grease, or oxidation that may hinder adhesion. For smooth metals, consider roughening the surface slightly with sandpaper or a file. This creates more surface area for the glue to latch onto, enhancing its grip and creating a seamless bond.

Limitations: Knowing When to Seek Alternatives

While Krazy Glue can work wonders in bonding many types of metals together, it’s important to understand its limitations. Heavy load-bearing applications or extreme temperature conditions may require alternative solutions such as specialized metal adhesives or welding techniques. These alternatives provide the strength and durability necessary for demanding situations. By recognizing these limitations, you can make informed decisions and ensure the success of your metal bonding projects.

What Surface Preparation is Required for Using Krazy Glue on Metal?

To achieve strong and long-lasting bonds when using Krazy Glue on metal, proper surface preparation is essential. In this article, we will explore the step-by-step process of surface preparation to ensure successful adhesive application.

- Cleaning the Metal Surface: Start by thoroughly cleaning the metal surface to remove any dirt, dust, grease, or other contaminants. A solution of mild detergent or dish soap mixed with water can be used for this purpose. Gently scrub the metal surface using a soft cloth or sponge to eliminate unwanted particles. Rinse the surface thoroughly with clean water and allow it to dry completely.

- Removing Stubborn Grease or Oil: In some cases, stubborn grease or oil may require a more aggressive approach. Acetone or rubbing alcohol are commonly used solvents that effectively dissolve grease and oil. Apply the solvent to a clean cloth and wipe the metal surface until it is completely clean. It is important to work in a well-ventilated area and follow all safety precautions when using solvents.

- Lightly Roughening the Surface: To enhance bond strength, lightly roughen the metal surface using fine-grit sandpaper or a wire brush. This creates small abrasions on the surface, providing more area for the adhesive to grip onto. However, be cautious not to over-sand the surface as it may damage the metal or create uneven areas.

- Removing Residue: After roughening the surface, remove any residue left behind. Use a clean cloth dampened with water or an appropriate solvent (depending on the type of residue) to wipe the surface clean. Ensure that the surface is completely dry before proceeding with adhesive application.

By following these steps, you can effectively prepare your metal surface for the magic of Krazy Glue. The proper surface preparation will help you achieve strong and durable bonds that will withstand the test of time.

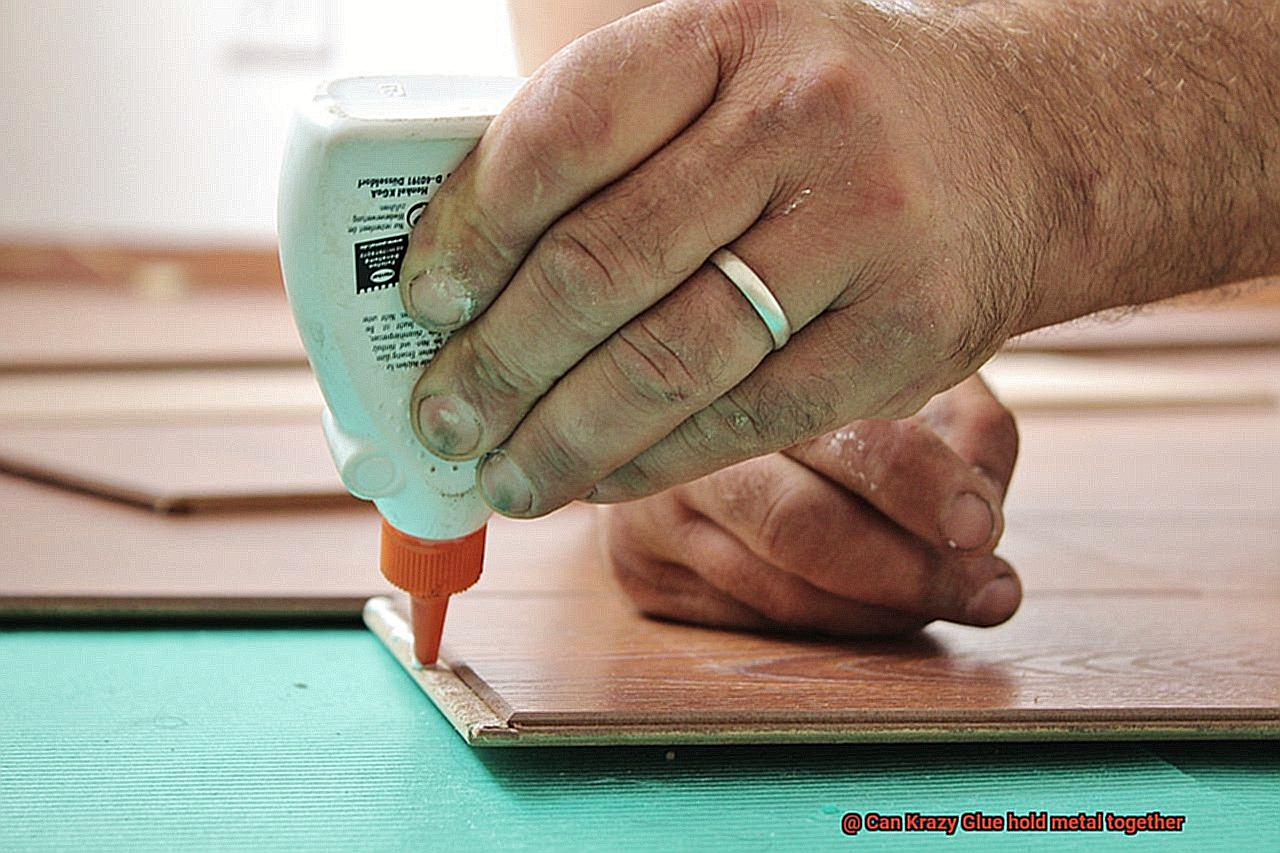

How to Apply Krazy Glue to Metal?

When it comes to bonding metal, Krazy Glue is a superhero in disguise. Its incredible strength and lightning-fast drying time make it the go-to adhesive for all your metal bonding needs. Whether you’re fixing a broken piece of jewelry or embarking on an exciting DIY project, here’s a step-by-step guide on how to apply Krazy Glue to metal.

Step 1: Clean the Surfaces

Before diving into the world of bonding, it’s crucial to prepare the battleground. Take a clean cloth and drench it in the elixir of rubbing alcohol or acetone. Wipe down those metal surfaces like a surgeon prepping for surgery. Get rid of any dirt, grease, or debris that may stand in the way of a perfect bond.

Step 2: Apply Sparingly

Remember, with great power comes great responsibility – and that applies to Krazy Glue too. Just a drop or two is all you need to conquer the metal world. Grab that trusty Krazy Glue bottle and let the adhesive flow like a river onto one of the metal surfaces that need uniting. Use the tip of the bottle to spread the glue in a thin, even layer. Don’t go overboard or you’ll end up in a sticky situation.

Step 3: Press Firmly

Now it’s time for some muscle. Push those metal surfaces together with all your might – applying pressure like a blacksmith forging steel. Hold them firmly for what seems like an eternity, but in reality, just a few seconds will do the trick. If you want extra security, arm yourself with clamps or tape to keep everything aligned and in place during this bonding battle.

Step 4: Let It Cure

Patience is a virtue, my friend. Let your creation bask in glory and dryness for a minimum of 24 hours. No movement, no stress – just pure bonding bliss. Allow the Krazy Glue to work its magic and form an unbreakable bond that can withstand the test of time.

Step 5: Clean Up Excess Glue

In every battle, there are casualties. If any excess glue dares to escape during the bonding process, wipe it away like a true warrior. Grab a clean cloth or tissue and banish that unwanted intruder. Act swiftly, for once the glue has dried, it becomes a stubborn foe that may require solvents or scraping to defeat.

Does Krazy Glue Work on All Types of Metals?

Are you wondering if Krazy Glue can work its magic on all types of metals? As an expert on adhesives, I’m here to shed some light on this sticky subject. While Krazy Glue is indeed a popular choice for bonding various materials, including metals, there are a few factors that can affect its effectiveness. Let’s dive into the world of metals and explore how different factors can impact the bonding potential of Krazy Glue.

The Influence of Metal Type:

Metals come in different varieties, ranging from ferrous (containing iron) to non-ferrous (without iron) metals. When it comes to bonding with Krazy Glue, non-ferrous metals like aluminum, copper, and brass are more compatible. These metals have relatively smooth surfaces that provide a good contact area for the adhesive to grip onto.

However, ferrous metals like steel or cast iron may pose challenges as they have higher surface energy and are prone to oxidation. For these metals, epoxy-based adhesives or specialized metal bonding glues may be better suited.

Importance of Surface Preparation:

A clean surface is crucial for a strong bond between metal and adhesive. Before applying Krazy Glue, make sure to clean the metal surface thoroughly to remove any dirt, grease, or rust that could hinder adhesion.

Using an appropriate solvent or degreaser will do the trick. Additionally, roughening the metal surface slightly with sandpaper can help enhance the bond, especially for metals with smooth or non-porous surfaces.

Impact of Moisture:

Krazy Glue works by reacting with moisture in the air to create a strong bond. If the metal surface is extremely dry or lacks moisture, the adhesive may not cure properly, leading to a weaker bond.

Ensure that there is enough moisture in the air or consider using a primer or activator specifically designed for bonding metals with cyanoacrylate adhesives to optimize bonding strength.

Surface Coatings and Finishes:

Metals may have surface coatings or finishes that can affect the adhesive’s performance. Metals with oil, grease, or rust need proper cleaning and preparation before applying any adhesive.

Removing these contaminants ensures better adhesion and increases the chances of a successful bond. Using a specialized metal cleaner or primer can further enhance the bond by providing an optimal surface for the adhesive to grip onto.

Consideration for High-Stress Applications:

While Krazy Glue can hold many types of metals together, it may not be suitable for load-bearing or high-stress applications. If you’re looking to bond metals under extreme conditions or heavy loads, it is advisable to explore other adhesives specifically formulated for those purposes.

Consult with experts or refer to product specifications to ensure you choose the right adhesive for your specific needs.

Is Krazy Glue Suitable for Load-Bearing or High-Stress Applications?

Krazy Glue, known for its strong bonding properties, is a popular choice for joining materials like wood, plastic, ceramics, and even some metals. However, it may not always be suitable for load-bearing or high-stress applications.

Load-bearing applications require adhesive that can support heavy weights and withstand significant forces. High-stress applications involve intense pressure or movement. While Krazy Glue can provide a strong initial bond, it may lack the necessary strength and flexibility for long-term durability in these conditions.

Factors such as the type of metal being bonded, surface preparation, and the specific load or stress applied can affect Krazy Glue’s performance. It is generally better suited for lightweight applications or situations with minimal force or movement, like small metal components such as jewelry or household items.

However, for heavy machinery, structural components, or anything requiring long-term reliability, other adhesives or mechanical fasteners are recommended. Epoxy adhesives, structural adhesives, or specialized metal bonding adhesives offer stronger bonds and greater resistance to stress and load-bearing requirements.

To ensure safety and bond integrity, it is crucial to consider specific application requirements and consult experts or manufacturers. Using the wrong adhesive can lead to failure or damage.

While Krazy Glue works wonders in many situations, it may not be the superhero we need for load-bearing or high-stress applications involving metal bonding. Explore alternatives that provide superior strength, flexibility, and resistance to environmental conditions and loads.

Factors to Consider When Using Krazy Glue on Metal

When using Krazy Glue on metal surfaces, there are several factors to consider to ensure a successful bond:

- Surface preparation: Clean the metal surface thoroughly to remove any dirt, oil, or rust. Use a mild detergent and water solution, then dry it completely before applying the glue.

- Type of metal: Different metals have varying surface properties that can affect the bond strength. Smooth metals like aluminum or stainless steel may require sanding to roughen the surface and enhance adhesive adhesion.

- Temperature and humidity: Krazy Glue performs best at room temperature, typically between 70°F and 90°F (21°C – 32°C). Extreme temperatures can affect the adhesive properties, so avoid using it in extremely hot or cold conditions.

- Application technique: Apply a thin layer of glue on both surfaces to be bonded. Avoid applying excessive glue as it can create a mess and weaken the bond. Press the parts together firmly and hold them in place for a few minutes to ensure a secure attachment.

- Curing time: The curing time for Krazy Glue on metal can vary depending on the specific product and environmental conditions. Follow the instructions provided by the manufacturer to allow sufficient time for the adhesive to fully cure.

- Strength requirements: Consider the strength requirements of the bond. Krazy Glue is suitable for lightweight and non-load-bearing applications but may not be suitable for heavy-duty or structural bonding. For such applications, consider using specialized adhesives designed specifically for metal bonding.

- Longevity: Krazy Glue provides a strong initial bond, but its durability in certain environments may vary. Factors like exposure to water, extreme temperatures, or chemicals can affect the bond over time. If long-term durability is essential, explore alternative adhesive options.

Alternatives to Krazy Glue for Bonding Metal

When it comes to bonding metal, Krazy Glue may not always be the best option. Luckily, there are plenty of alternatives that will have your metal pieces sticking together like they were forged as one. Let’s explore some powerful alternatives and find the perfect solution for your metal bonding needs.

First up on our list is epoxy adhesive. This mighty adhesive consists of two components, a resin and a hardener, which are mixed together before application. Epoxy is renowned for its exceptional strength and durability, making it a top choice for bonding metals. Not only does it provide a stronger bond than Krazy Glue, but it also boasts resistance to heat, chemicals, and moisture. So if you’re tackling a project that requires serious strength and can withstand harsh conditions, epoxy is the way to go.

Next, we have the superhero of adhesives – super glue, also known as cyanoacrylate adhesive. While it works similarly to Krazy Glue, super glue may have different formulations and strengths. Some super glues are specifically designed for bonding metal and offer excellent adhesion properties. Just make sure to check if the specific super glue you choose is compatible with the type of metal you’re working with.

For larger or thicker metal pieces, welding might be your best bet. Welding involves melting the base metal and adding a filler material to create a strong bond. It is commonly used in industries like construction and automotive manufacturing due to its unmatched strength. However, keep in mind that welding requires specialized equipment and expertise, making it less accessible for DIY projects.

If you’re working on smaller metal bonding applications, specialized metal adhesives like JB Weld or Loctite Metal Epoxy are excellent options. These adhesives are formulated specifically for bonding metal and provide high-strength bonds. They create a chemical reaction that results in a robust bond between the adhesive and the metal surface.

When disassembly or adjustment is needed, mechanical fasteners like screws, bolts, or rivets are reliable options. These methods involve creating holes in the metal pieces and securing them with the fasteners. Mechanical fasteners provide a strong and dependable bond, especially when flexibility is required.

Lastly, let’s not forget about soldering and brazing. These techniques involve melting a filler metal onto the metal surfaces to create a bond. Soldering is commonly used in electrical and plumbing applications, while brazing uses higher temperatures and different filler metals. Both techniques are great for creating robust and conductive bonds in specific situations.

When choosing an alternative to Krazy Glue for bonding metal, consider factors such as the type of metal, strength requirements, temperature resistance, and environmental conditions. Consulting with a professional or conducting thorough research on the best adhesive for your specific metal bonding needs is highly recommended.

w-iHL3tN__A” >

Also Read: Does Krazy Glue Work on Metal?

Conclusion

In conclusion, it is evident that Krazy Glue has the remarkable ability to securely bond metal together.

Its powerful adhesive properties create a strong and durable connection that withstands even the toughest conditions. Whether you’re fixing a broken piece of jewelry or assembling metal components for a DIY project, Krazy Glue proves to be a reliable solution.

So, next time you need to join metal pieces together, trust in the strength and reliability of Krazy Glue.