Carbon fiber, the superhero of materials, has taken center stage in a wide range of industries. Its unbeatable strength-to-weight ratio and unmatched durability make it the go-to choice for high-performance applications. But what about when it comes to bonding or repairing carbon fiber components? Can super glue save the day?

In this blog post, we dive into the world of bonding carbon fiber with super glue. We’ll uncover its advantages and disadvantages, providing you with invaluable insights and expert tips for successful application. So whether you’re a DIY aficionado or just curious about the magic of carbon fiber, keep reading to unlock the secrets of this innovative adhesive technique.

Advantages:

Contents

- 1 What is Super Glue?

- 2 What is Carbon Fiber?

- 3 Cleaning and Preparing the Surfaces

- 4 Roughening the Carbon Fiber Surface

- 5 Applying Super Glue to Carbon Fiber

- 6 Advantages of Using Super Glue on Carbon Fiber

- 7 Disadvantages of Using Super Glue on Carbon Fiber

- 8 Alternatives to Super Glue for Bonding Carbon Fiber

- 9 Conclusion

Super glue swoops in with its lightning-fast bonding capabilities as one of its major advantages for carbon fiber. Unlike other adhesives that demand clamping for ages, super glue gets to work swiftly, ensuring efficient repairs. Moreover, it forms a robust bond between carbon fiber components, preserving their structural integrity and maintaining their inherent strength.

On top of that, super glue is readily available and user-friendly—perfect for professionals and amateurs alike. Its nifty applicator nozzle allows precise application with minimal mess or excess residue.

Disadvantages:

While super glue flexes its muscles in many areas, it’s important to acknowledge its limitations when dealing with carbon fiber. One notable drawback is that over time, super glue can become brittle—especially under extreme temperatures or prolonged UV exposure. This vulnerability can potentially weaken the bond between carbon fiber pieces, requiring regular inspections and necessary touch-ups.

Tips for Successful Application:

Preparation is key to achieving a solid bond. Thoroughly clean the surfaces you plan to bond—say goodbye to dust, oils, or any sneaky contaminants. Gently sanding those areas creates a slightly rough texture that enhances adhesion.

When applying super glue, remember that less is more. A thin, even layer usually does the trick for a secure bond. Hold the pieces firmly in place for the recommended curing time and give the adhesive ample time to fully cure before subjecting the bonded components to stress or load.

What is Super Glue?

Super glue, known as cyanoacrylate adhesive, is a versatile and fast-acting adhesive that can securely bond a wide range of materials together. Whether you’re fixing a broken item or working on a crafting project, super glue is the go-to adhesive for quick and strong bonds. In this article, we will delve into the world of super glue, exploring its composition, uses, and essential safety tips.

Super glue is a transparent liquid adhesive that forms an unyielding bond when exposed to moisture. This powerful adhesive works by undergoing polymerization, where long chains of molecules link together to solidify the connection between two surfaces. With its lightning-fast bonding properties, super glue excels in precision applications and securing small parts.

Diverse Uses of Super Glue:

Super glue boasts a multitude of applications. Here are some common uses:

- Repairing broken items: From restoring shattered ceramic mugs to fixing cracked plastic toys, super glue provides resilient and durable bonds.

- Crafting projects: Whether you’re working with wood, metal, or plastic in your crafting endeavors, super glue ensures a secure fusion between different materials.

- Household repairs: Super glue comes in handy for fixing wobbly furniture joints, mending shattered glasses or ornaments, and even reattaching detached shoe soles.

- Model making: When constructing models or miniatures, super glue’s precision and rapid bonding qualities make it an excellent choice for piecing together intricate parts.

Using Super Glue Safely:

While super glue offers superior adhesion, it is crucial to handle it with care. Here are some safety tips to bear in mind:

- Ventilation: Ensure you work in a well-ventilated area to avoid inhaling any fumes emitted by the adhesive.

- Skin protection: Don gloves when using super glue and avoid contact with your skin. If accidental contact occurs, rinse the area with warm, soapy water.

- Eye protection: Safeguard your eyes by wearing safety goggles when working with super glue to prevent any inadvertent splashes.

- Clothing preservation: Steer clear of getting super glue on your clothes, as it can permanently bond fabric together. If glue does come into contact with your garments, gently peel it off while it’s still wet or seek professional assistance.

What is Carbon Fiber?

Imagine a material so strong it can withstand incredible forces, yet so light it defies gravity. Meet carbon fiber – the superhero of materials that possesses the power to revolutionize industries and push the boundaries of what we thought was possible.

The Origins:

Carbon fiber is not your average material. It is made up of tightly woven strands of carbon atoms, creating a composite that is lightweight, yet incredibly strong. This magical material is born through a process called carbonization, where precursor materials like polyacrylonitrile or rayon fibers undergo a series of chemical reactions at high temperatures to transform into the carbon fibers we know and love.

Superpower #1: Strength and Lightness:

Carbon fiber’s first superpower lies in its remarkable strength. Pound for pound, it is stronger than steel and aluminum, making it a go-to choice for applications that require immense strength without sacrificing weight. It is about five times lighter than steel and two times lighter than aluminum, making it a game-changer in industries where weight reduction is critical, such as aerospace.

Superpower #2: Stiffness and Stability:

Another superpower of carbon fiber lies in its stiffness. It possesses a high modulus of elasticity, meaning it does not easily deform under load. This characteristic makes it perfect for constructing high-performance sports equipment like tennis rackets or bicycles that require rigidity and stability to enhance performance.

Superpower #3: Resistance to Corrosion:

But wait, there’s more. Carbon fiber also possesses a unique ability to resist corrosion and chemical damage. Unlike metals that rust or corrode when exposed to moisture or harsh chemicals, carbon fiber remains unscathed. This makes it an ideal choice for marine applications or chemical processing plants where corrosion can be a concern.

The Future:

As we continue to uncover the full potential of this extraordinary material, the possibilities are endless. From aerospace to automotive, sports equipment to construction, carbon fiber is revolutionizing industries across the globe. With its unmatched strength, lightness, and durability, designers and engineers are embracing carbon fiber as their go-to material.

Cleaning and Preparing the Surfaces

Properly cleaning and preparing surfaces is a crucial step in bonding carbon fiber with super glue. Carbon fiber surfaces, despite their smooth appearance, can actually hinder adhesive bonding due to the presence of release agents or contaminants. To avoid weak bonds that may fail under stress, it is essential to dedicate time to surface preparation.

Here are the steps you should follow to achieve a rock-solid bond:

- Clean the carbon fiber surface: Use a mild detergent or soap and water solution to gently scrub away dirt, dust, or grease. Avoid harsh chemicals or abrasive cleaners that could damage the carbon fiber.

- Thoroughly dry the surface: Moisture can interfere with the adhesive’s ability to bond properly, so ensure there is no residual water on the surface. You can use a clean towel or allow it to air dry.

- Roughen the surface slightly: Lightly sand the carbon fiber surface with fine-grit sandpaper to create a roughened texture. This provides more surface area for the adhesive to grip onto. Remember, the goal is not to remove material but to enhance adhesion.

- Remove any sanding dust: After sanding, use a lint-free cloth or compressed air to eliminate any particles generated during the process.

By following these steps, you will be ready to bond your carbon fiber with super glue.

It is important to note that not all super glues are created equal. Choosing a super glue that is compatible with both the carbon fiber and the material you are bonding it to is crucial. Always consult the adhesive manufacturer’s guidelines and recommendations for bonding carbon fiber.

Roughening the Carbon Fiber Surface

Imagine working on a project with carbon fiber, aiming to secure its pieces together with super glue. However, you soon realize that carbon fiber’s smooth and slippery surface poses a challenge for adhesives. So, how can you achieve a bond as strong as the Hulk’s grip? The answer lies in roughening the carbon fiber surface. In this comprehensive guide, we will explore the significance of roughening and delve into various methods to achieve a rock-solid bond that will make you feel like a glue guru.

Why Roughening Matters:

- Carbon fiber’s sleek and slick nature hinders adhesive bonding.

- Roughening the surface adds texture and increases the surface area for glue to grip onto.

- A roughened surface enhances bond strength and durability.

Sanding, The Gentle Touch:

- Gently sand the carbon fiber surface using fine-grit sandpaper.

- This removes any glossy finish and creates a slightly rougher texture.

- Exercise caution to prevent excessive sanding that may harm the delicate carbon fiber.

Wire Brushes and Abrasive Pads:

- Use wire brushes or abrasive pads to gently rub the surface.

- These tools create tiny grooves and scratches, providing better grip for the adhesive.

- Remember, apply gentle pressure – there’s no need for Hulk-like strength.

Chemical Etching, For the Pros:

- Employ specific etching solutions designed for carbon fiber.

- These chemicals react with the material, creating a rougher surface.

- Professional expertise is required for this method.

Cleanliness is Next to Glue-liness:

- Thoroughly clean the carbon fiber surface before applying adhesive.

- Any dirt, dust, or grease can hinder bonding.

- Utilize mild cleaners or rubbing alcohol for a spotless surface.

The Finishing Touch – Adhesion Promoters:

- Prime or coat the roughened surface with an adhesion promoter tailored for carbon fiber.

- This step enhances the bond between carbon fiber and adhesive, improving strength and durability.

Applying Super Glue to Carbon Fiber

Unlock the secrets to achieving a bond as unbreakable as the Hulk’s grip when working with carbon fiber and super glue. Carbon fiber, a lightweight and high-strength material, finds its applications in industries like aerospace, automotive, and sporting goods. However, bonding carbon fiber requires careful consideration of adhesive compatibility to ensure a durable and long-lasting bond.

To start, proper surface preparation is crucial when applying super glue to carbon fiber. Begin by cleaning the carbon fiber with a mild detergent or alcohol solution, removing any dirt, oils, or contaminants that may hinder the bonding process. A pristine surface is essential for achieving a strong bond.

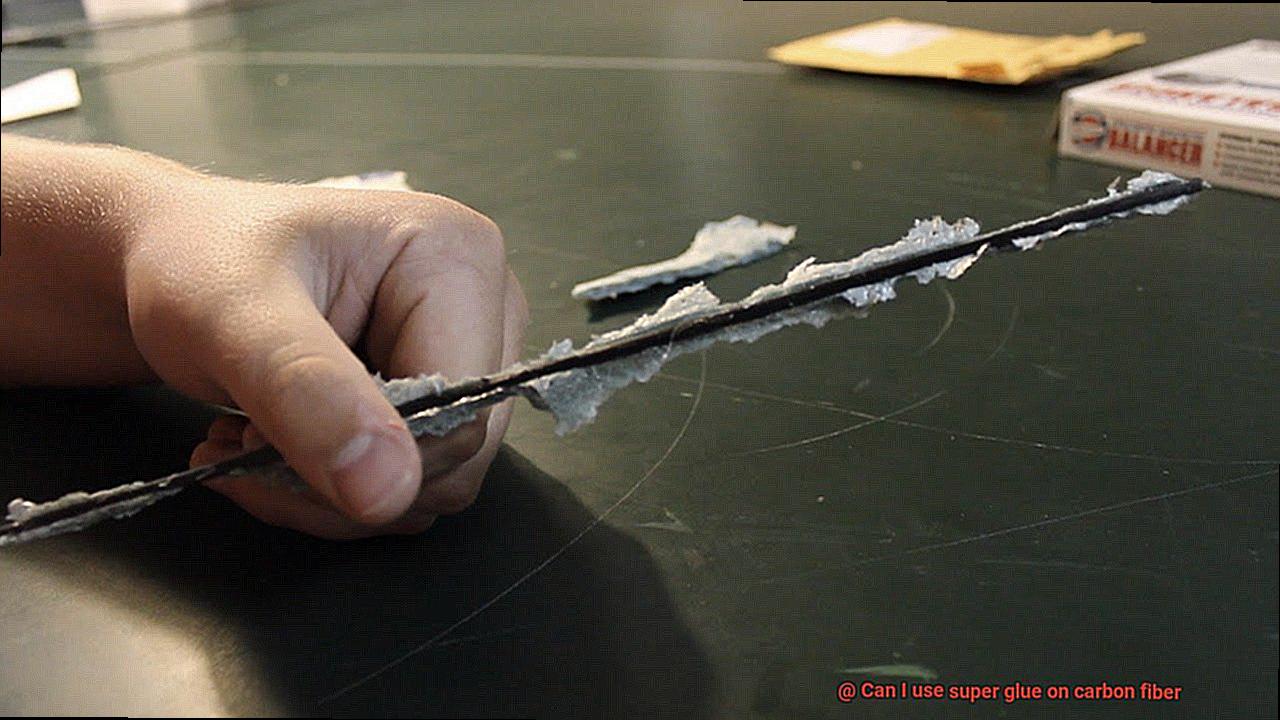

Next, enhance adhesion by lightly sanding the carbon fiber using fine-grit sandpaper. This creates a rough texture akin to Velcro hooks and loops that improve the adhesive’s grip on the material. The more secure the bond, the stronger it will be.

Now it’s time to apply the super glue, but remember: less is more. Use a small amount of glue and distribute it evenly on the surface. Excess glue can result in messy bond lines and weaken the overall strength. Apply just enough to cover the area without any oozing.

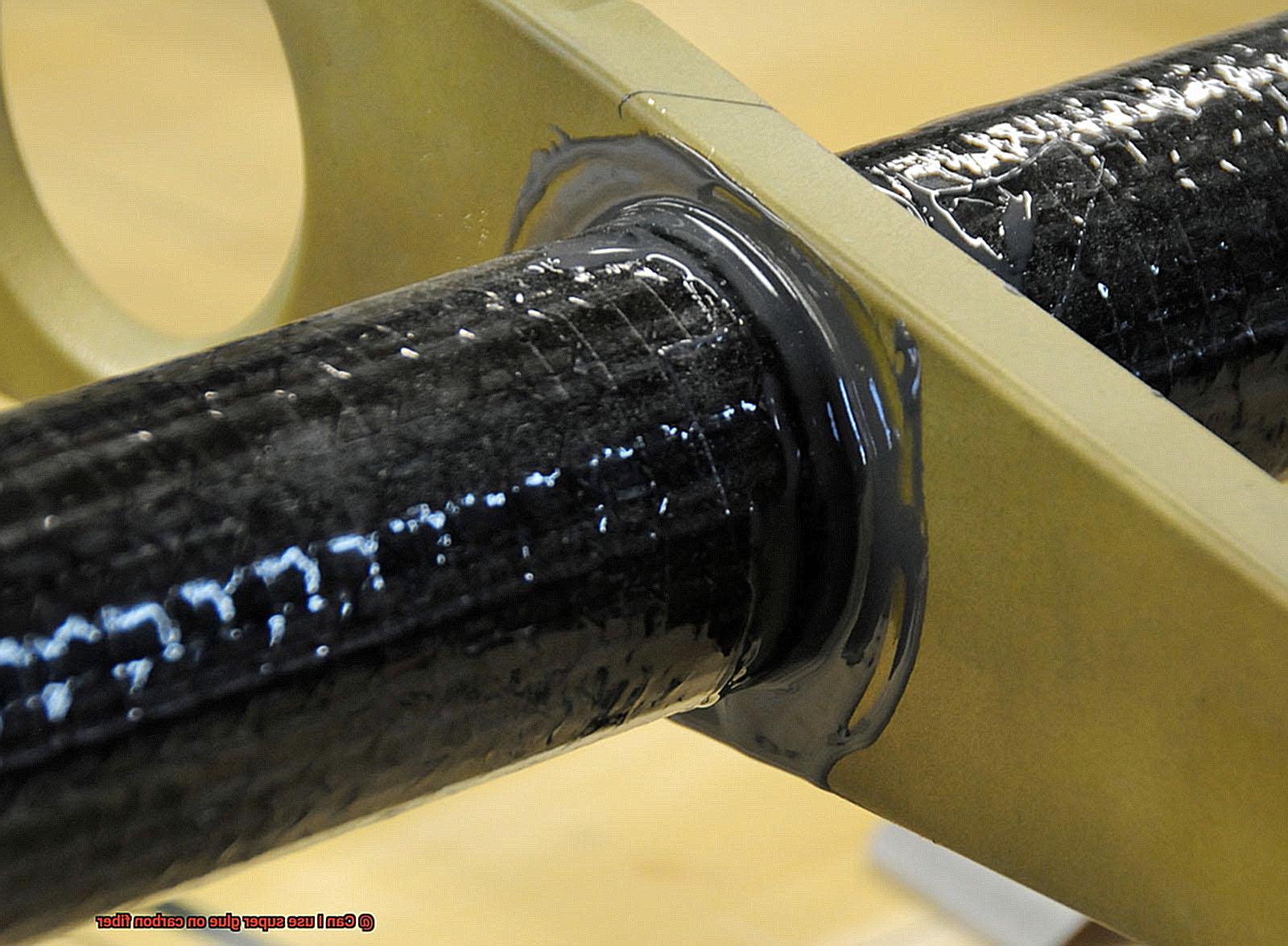

Once applied, apply pressure or use clamps to hold the bonded parts firmly until the glue fully cures. This ensures consistent contact between the surfaces and promotes a stronger bond. Experiment with clamps, weights, or your own hand strength – just be cautious not to accidentally stick yourself to the carbon fiber.

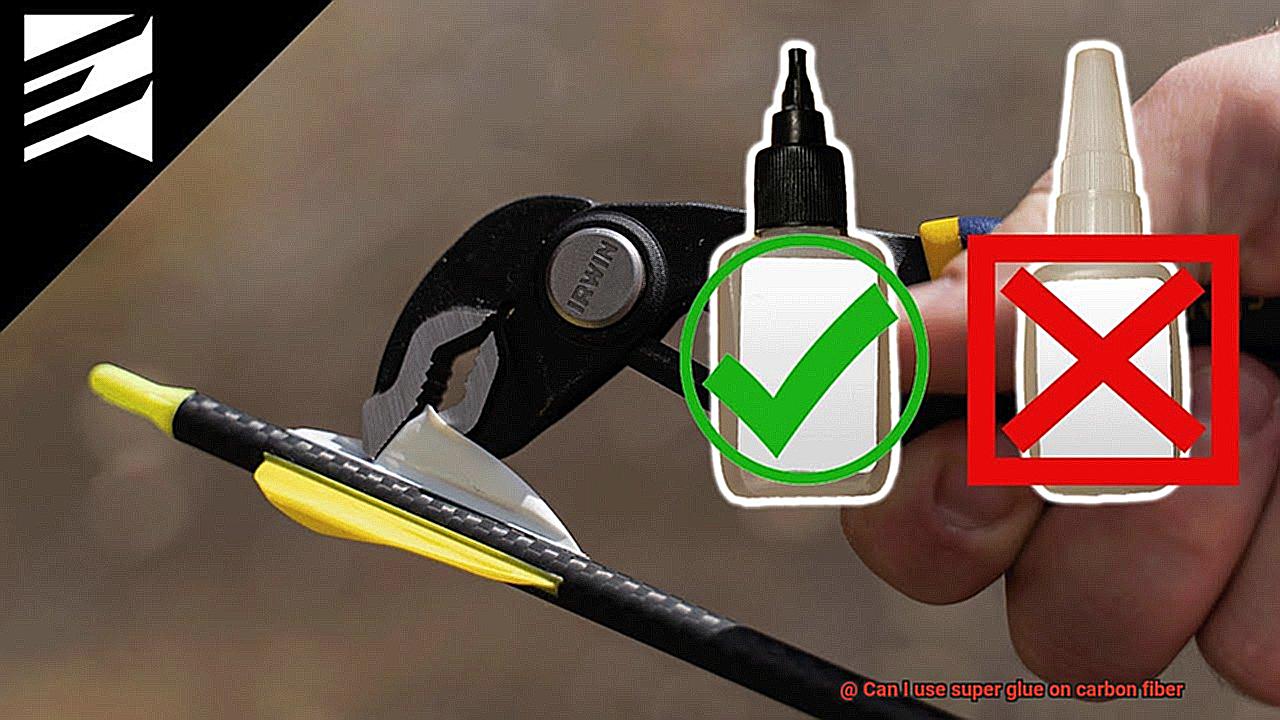

It’s important to note that not all super glues are suitable for bonding carbon fiber. Some lack necessary strength or compatibility with this material. To guarantee success, choose an adhesive specifically designed for bonding carbon fiber or consult professionals experienced in this field.

Lastly, if a super glue bond on carbon fiber fails or needs removal, separating the parts without causing damage can be challenging. Seeking professional assistance or employing specialized techniques may become necessary in such cases.

Advantages of Using Super Glue on Carbon Fiber

This powerful adhesive offers a multitude of advantages when it comes to working with carbon fiber. Whether you’re a professional in the aerospace industry or a hobbyist working on your latest automotive masterpiece, super glue is a must-have tool in your arsenal.

Advantages of Using Super Glue on Carbon Fiber:

- Strong Bonding: Super glue forms an almost instant and incredibly strong bond when applied to carbon fiber surfaces. This ensures that your carbon fiber components stay firmly in place, even under high-stress conditions. Whether you’re repairing a broken part or joining different components together, super glue provides a reliable and durable bond.

- Quick and Easy Application: Unlike other adhesives that require mixing or curing time, super glue can be applied directly from the bottle onto the carbon fiber surface. Its fast-drying nature allows you to get back to work in no time, making it perfect for projects with tight deadlines. No more waiting around for hours for the adhesive to set.

- Versatility: Super glue is a versatile adhesive that can bond different surfaces, making it suitable for a wide range of applications involving carbon fiber. From automotive repairs to aerospace projects, super glue is the go-to adhesive for bonding carbon fiber components together.

- Resistance to Temperature and Chemicals: Carbon fiber components are often exposed to extreme temperature variations and harsh chemicals. Fortunately, super glue exhibits excellent resistance to both high and low temperatures, ensuring that the bond remains intact even in challenging environmental conditions. It is also resistant to many chemicals, making it ideal for use in various industries.

- Minimal Weight Addition: Carbon fiber is valued for its lightweight properties, and using super glue for bonding helps preserve that. Unlike some other adhesives that can add significant weight to the final assembly, super glue’s thin layer results in minimal weight addition. This allows your carbon fiber components to remain lightweight and agile, without compromising their structural integrity.

- Aesthetically Pleasing Results: Super glue dries clear, leaving behind a virtually invisible bond. This is particularly advantageous for carbon fiber applications where aesthetics are important. Whether you’re working on a sleek automotive design or a cutting-edge aerospace project, the transparent nature of super glue ensures that the bond doesn’t detract from the overall appearance of the carbon fiber part, resulting in a seamless and professional finish.

Disadvantages of Using Super Glue on Carbon Fiber

Using super glue on carbon fiber can have several disadvantages that make it less than ideal for this material. Carbon fiber is a lightweight and incredibly strong material that requires a specialized adhesive to ensure a strong and durable bond. Super glue may not provide the necessary strength for carbon fiber surfaces, potentially leading to failures or damages.

Flexibility is another drawback of using super glue on carbon fiber. Carbon fiber components often require flexibility to withstand stress, vibrations, and movements. However, super glue tends to harden and become brittle over time, making it prone to cracking or breaking when subjected to flexing or bending forces. This lack of flexibility compromises the structural integrity of carbon fiber components.

Super glue also lacks resistance to extreme temperatures. Carbon fiber is commonly used in applications with high temperatures, such as aerospace or automotive industries. Super glue may not have the necessary heat resistance to maintain its strength and integrity in these conditions. It can soften, melt, or lose its adhesive properties when exposed to extreme heat, leading to bond failure and component damage.

Chemical resistance is another crucial factor when choosing an adhesive for carbon fiber. Carbon fiber components are often exposed to various chemicals or solvents in industrial or manufacturing settings. Unfortunately, super glue may not have the necessary chemical resistance to withstand these substances. This can result in a weakened bond or complete failure of the adhesive when exposed to chemicals, compromising the stability and reliability of carbon fiber components.

In addition to its functional drawbacks, super glue can also negatively impact the appearance of carbon fiber. Carbon fiber is renowned for its sleek and sophisticated look, and any visible residue or damage caused by using super glue can significantly diminish its aesthetic appeal. Removing super glue from carbon fiber surfaces without causing further damage can be a challenging task, further adding to the disadvantages of using this adhesive on this material.

Lastly, the lack of reversibility is a significant disadvantage when it comes to using super glue on carbon fiber. In some cases, it might be necessary to remove or replace certain carbon fiber components. However, super glue can be difficult to remove without damaging the carbon fiber itself. This lack of reversibility can make repairs or modifications more complicated and costly.

Alternatives to Super Glue for Bonding Carbon Fiber

When it comes to bonding carbon fiber, super glue falls short in providing the necessary strength and durability for this high-performance material. Fortunately, there are alternative options available that offer stronger, more reliable bonds. In this article, we will delve into these alternatives and discuss their advantages and disadvantages.

Epoxy Resin:

- Consists of a resin and a hardener.

- Provides excellent bonding strength, durability, and resistance to chemicals and heat.

- Widely used in industries such as aerospace and automotive.

- Withstands stresses and strains to maintain a strong bond between carbon fiber surfaces.

Structural Adhesive:

- Specifically formulated for high-strength bonding applications.

- Ensures a durable and reliable bond between carbon fiber surfaces.

- Varieties include methacrylate adhesives (high bonding strength and flexibility) and polyurethane adhesives (strong bond with good impact resistance and flexibility).

- Commonly employed in construction, aerospace, and automotive industries.

Mechanical Fasteners:

- Bolts, screws, rivets, or clips can be used as an alternative to adhesive bonding.

- Establishes a dependable connection between carbon fiber parts.

- Allows for easy disassembly and reassembly if needed.

- Requires careful drilling to avoid weakening the carbon fiber structure.

wVmHDLPc2YA” >

Also Read: How to Glue Carbon Fiber to Rubber

Conclusion

Yes, you can use super glue on carbon fiber. Carbon fiber is a strong and lightweight material commonly used in various industries, including aerospace and automotive. When it comes to bonding carbon fiber, using super glue can be an effective option. Super glue, also known as cyanoacrylate adhesive, forms a strong bond that can withstand the rigors of everyday use.

However, it’s important to note that not all super glues are suitable for use on carbon fiber. It’s recommended to choose a super glue specifically formulated for bonding plastics and composites. These types of super glues have special additives that enhance adhesion to carbon fiber surfaces.

Before applying the super glue, make sure the carbon fiber surface is clean and free from any dirt or debris. You can use rubbing alcohol or acetone to clean the surface thoroughly. Once the surface is clean, apply a small amount of super glue to one of the surfaces you want to bond together.

Press the two surfaces firmly together and hold them in place for a few minutes to allow the adhesive to set properly. Keep in mind that carbon fiber has a smooth and glossy surface, which may require some pressure during bonding to ensure maximum contact between the surfaces.

After the adhesive has cured, it’s essential to check if the bond is strong and secure. Give it a gentle tug or apply some force to see if there are any signs of weakness or separation. If everything looks good, you can proceed with confidence knowing that your carbon fiber parts are securely bonded.

In conclusion, using super glue on carbon fiber is possible and can provide a reliable bond when done correctly. Just remember to choose a suitable adhesive formulated for plastics and composites, clean the surface thoroughly before bonding, apply pressure during bonding, and check for strength after curing.