Get ready to embark on a thrilling journey through the realm of EVA foam glues. Whether you’re a cosplay connoisseur, a DIY daredevil, or just someone who loves getting their hands dirty with crafts, we know how crucial it is to find the perfect glue for your EVA foam projects. But fear not. In this blog post, we’ll be your trusty guide, leading you through the maze of options and helping you discover the absolute best glue for bonding EVA foam.

So, let’s not waste any more time. It’s time to roll up our sleeves and dive headfirst into the pros and cons of each contender in the gluing universe. By the end of this adventure, you’ll have all the knowledge you need to make an informed decision and achieve flawless results with your EVA foam projects.

[Note: Add detailed information on advantages and disadvantages of various glue options, along with other relevant information in the main body of the blog post.]

Understanding the Properties of EVA Foam

Contents

- 1 Understanding the Properties of EVA Foam

- 2 Essential Factors to Consider When Choosing Glue for EVA Foam

- 3 Contact Cement: An Ideal Choice for Bonding EVA Foam

- 4 EVA Foam Glue: A Specific Glue for Optimal Adhesion and Flexibility

- 5 Hot Glue: Quick Bonding but Not Always Durable

- 6 Super Glue: Fast-Acting but May Not Provide Flexibility

- 7 Two-Part Epoxy: Strong and Durable Bond with Flexibility

- 8 Other Types of Glues Suitable for Bonding EVA Foam

- 9 Conclusion

EVA foam, also known as ethylene-vinyl acetate foam, is a versatile material that has gained popularity in various industries for its unique properties. When selecting a glue for EVA foam, it is important to understand these properties and how they should be taken into consideration. Here are the key properties of EVA foam and their importance in adhesive selection:

- Cushioning and Shock Absorption: EVA foam is renowned for its excellent cushioning and shock absorption capabilities. It provides a soft and comfortable surface that can resist impact. When choosing a glue for EVA foam, it is crucial not to compromise its ability to absorb shocks. The glue should maintain the foam’s cushioning properties while providing a strong bond.

- Flexibility and Elasticity: EVA foam is highly flexible and elastic, allowing it to bounce back to its original shape after being compressed or stretched. This property makes it suitable for applications that require repeated bending or flexing. The chosen glue should be able to withstand this flexibility and maintain a strong bond even under strain.

- Water Resistance: EVA foam is water-resistant and can resist moisture and water absorption. This property makes it ideal for outdoor applications or items that may come into contact with liquids. The glue used for EVA foam should also possess water resistance to ensure a durable bond that will not be compromised by exposure to moisture.

- Lightweight and Easy to Work With: EVA foam is lightweight and easy to cut, shape, and mold into various forms without losing its structural integrity. This characteristic allows for creativity and versatility in design and application. The chosen glue should be compatible with the cutting and shaping process of EVA foam, ensuring a seamless bond without damaging the material.

- UV Resistance: Prolonged exposure to sunlight can cause EVA foam to degrade and lose its color. UV resistance is an important consideration when using EVA foam outdoors. The glue selected should provide UV resistance to protect the foam from fading or deteriorating when exposed to sunlight.

Considering these properties is crucial when selecting the best glue for EVA foam. It ensures a strong and durable bond that preserves the integrity and functionality of EVA foam products. Different types of glues, such as contact cement, EVA foam glue, hot glue, super glue, and two-part epoxy, are commonly recommended for bonding EVA foam. Each has its own advantages and considerations, so it is important to choose the glue that best suits the specific requirements of your project.

Essential Factors to Consider When Choosing Glue for EVA Foam

When working with EVA foam, selecting the right glue is crucial for a successful project. Whether you’re creating cosplay armor, foam props, or crafting with this versatile material, choosing the correct adhesive can make all the difference. In this article, we’ll explore the essential factors to consider when selecting glue for EVA foam.

Adhesive Type:

- Contact cement: Offers a strong bond and is suitable for larger surface areas.

- Hot glue: Provides a quick bond, but may not be as durable for heavy-duty projects.

- Specialized EVA foam adhesive: Specifically designed for bonding EVA foam and offers excellent adhesion.

Bond Strength:

Choose a glue that provides a strong and durable bond to ensure your EVA foam creations hold together over time.

Drying Time:

Consider your project timeline and select a glue with a drying time that aligns with your needs. Some glues may require longer drying times, while others set quickly.

Flexibility:

EVA foam is known for its flexibility and ability to withstand bending and stretching. Choose an adhesive that can maintain its bond even under these conditions.

Toxicity:

Prioritize safety by selecting a non-toxic glue that is safe to use with EVA foam, especially in poorly ventilated areas or when working with children.

Application Method:

Consider the ease of application when choosing glue for EVA foam. Spray adhesives offer even coverage, while brush application allows for more precise control. Glue guns are suitable for smaller areas or intricate details.

Compatibility with Other Materials:

If you plan to bond EVA foam with other materials like fabric or plastic, ensure the glue is compatible with all materials involved to avoid damage or discoloration.

Contact Cement: An Ideal Choice for Bonding EVA Foam

When it comes to bonding EVA foam, contact cement is the superhero adhesive that saves the day. Its strong and durable hold makes it the ideal choice for a myriad of projects, from crafting cosplay costumes to creating shoe soles that defy gravity. But what makes contact cement the ultimate sidekick for EVA foam bonding?

First and foremost, contact cement forms a permanent bond when the two surfaces are pressed together. This means that once applied and dried, it creates an unbreakable connection that will withstand even the most vigorous adventures.

Contact cement comes in two flavors: water-based and solvent-based formulas. The water-based option is kinder to the environment and has a milder scent, while the solvent-based variant boasts a stronger bond and quicker drying time. Choose your weapon wisely based on your specific needs and preferences.

Applying contact cement is as easy as 1-2-Simply spread an even layer on both surfaces, let it dry until it becomes tacky, then join them together with precision. Once they’re united, repositioning becomes a Herculean task, so accuracy in alignment is key.

One of the superpowers of contact cement is its resistance to heat and moisture. This makes it perfect for projects where the foam may encounter these formidable foes, such as shoe soles or props used in outdoor settings. No need to fear the elements; contact cement has got your back.

However, not all EVA foams are compatible with this adhesive wonder. High-density or closed-cell foams may not adhere as strongly to contact cement’s charm. Always test the adhesive on a small, inconspicuous area before committing to a full-scale bonding adventure.

EVA Foam Glue: A Specific Glue for Optimal Adhesion and Flexibility

EVA foam is a versatile material with endless possibilities for crafts and projects. Its lightweight, flexible, and shock-absorbing properties make it a popular choice for creating costumes, props, and even shoe soles. However, the key to achieving optimal adhesion and flexibility with EVA foam lies in finding the right glue.

Why is EVA foam glue the go-to adhesive for this material? Let’s dive deeper into its benefits:

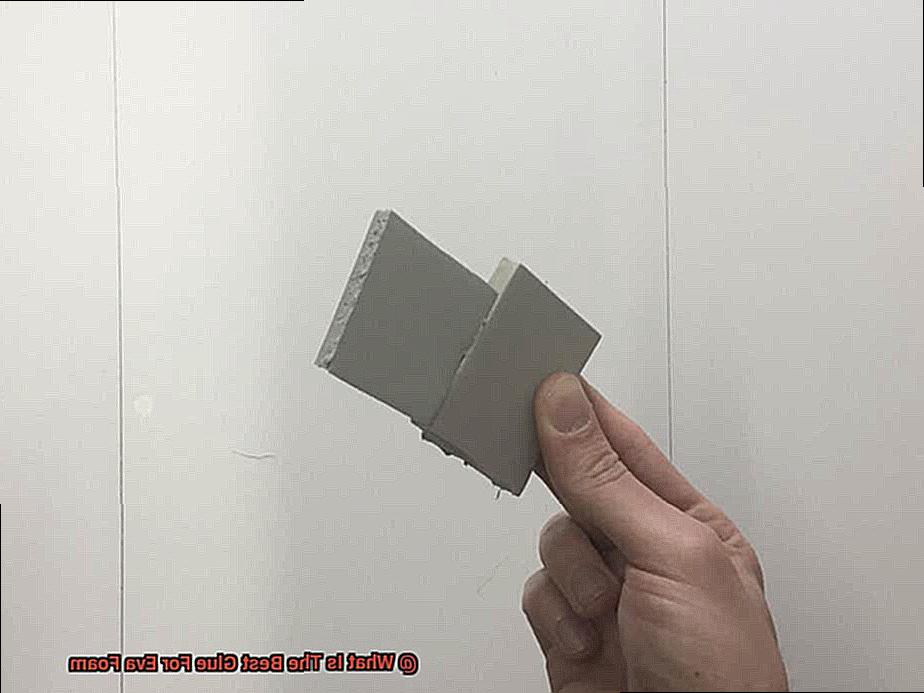

- Strong Adhesion: EVA foam glue is specially formulated with ingredients that promote exceptional adhesion to EVA foam surfaces. This means that the bond between foam pieces or between foam and other materials remains robust, even when subjected to bending, twisting, or stretching. No need to worry about your creations falling apart during those intense cosplay battles.

- Flexibility: Unlike regular glues that may become brittle or crack when flexed, EVA foam glue offers unparalleled flexibility. This allows the foam to maintain its shape while preserving the strength of the bond. So whether you’re crafting a costume that requires freedom of movement or designing shoe soles that need to withstand constant pressure, EVA foam glue will keep everything intact.

- Durability: EVA foam glue is often heat-resistant, moisture-resistant, and chemical-resistant. This exceptional durability makes it suitable for a wide range of applications. Whether you’re working on a project exposed to high temperatures or one that comes in contact with water or chemicals, rest assured that your bond will remain strong and intact.

- Easy to Use and Clean Up: Most EVA foam glues are water-based, making them incredibly user-friendly. They’re easy to apply and clean up, ensuring a seamless finish without any visible residue. No more worrying about messy glue application ruining your carefully crafted masterpiece.

To achieve optimal results with EVA foam glue, be sure to follow the manufacturer’s instructions for proper application and curing time. Some glues may require additional steps, such as surface preparation or priming, to ensure the best adhesion. It’s also wise to test the glue on a small, inconspicuous area of the foam before committing to the full application.

Hot Glue: Quick Bonding but Not Always Durable

Hot glue, the superhero of adhesives, is widely known for its quick bonding capabilities and ease of application. It’s like a trusty sidekick that dries within seconds, allowing for immediate use of the bonded materials. But when it comes to long-term use and bonding EVA foam, this superhero adhesive may not always be the best option.

EVA foam is a flexible material that can undergo stress and movement. While hot glue provides an initial strong bond, it may not be able to withstand the test of time. Over time, the constant stress on the foam can cause the hot glue bond to weaken, leading to potential failure.

But it’s not just time that poses a threat to hot glue’s durability. Extreme temperatures can also affect its bond strength. Whether it’s scorching summer heat or freezing winter cold, these temperature extremes can cause the hot glue to become brittle or lose its adhesive properties. Imagine your EVA foam creation falling apart when exposed to extreme weather conditions – not the heroic ending you had in mind.

So what are the alternatives? Well, fret not because there are a few options that offer better durability and bonding strength for EVA foam. One such adhesive is epoxy resin, the ultimate champion in durability and bond strength. It’s like the Iron Man of adhesives, providing unbeatable protection and strength for your foam projects. Contact adhesive is another worthy contender, forming an unbreakable bond when surfaces are pressed together. And let’s not forget about craft glues specifically designed for foam materials – they’re like the unsung heroes that provide reliable and durable bonds.

Ultimately, the choice of adhesive depends on factors such as your EVA foam project’s intended use and the level of durability required. If you’re looking for a quick fix or temporary bond, hot glue may still save the day. However, if you want your creation to stand the test of time and endure any challenge that comes its way, it’s worth considering alternative adhesives that offer greater durability.

Super Glue: Fast-Acting but May Not Provide Flexibility

Super glue, also known as cyanoacrylate adhesive, is a popular choice for bonding materials quickly and securely. Its fast-acting properties have made it a staple in many crafters’ toolkits. However, when it comes to working with EVA foam, super glue may not be the best adhesive option if flexibility is a key requirement.

EVA foam, known for its flexibility and cushioning properties, is commonly used in crafts, costumes, and cosplay props. It requires an adhesive that can withstand bending and stretching without compromising the bond. While super glue can initially create a strong bond between EVA foam pieces, its lack of flexibility becomes problematic over time.

Imagine spending hours crafting an intricate EVA foam cosplay armor, only to have it fall apart at the seams during your first heroic pose. Super glue simply doesn’t have the staying power needed for larger or more flexible EVA foam projects. It may become brittle and crack under stress or movement, putting all your hard work at risk of coming undone.

There are alternative adhesive options that offer better flexibility and durability for your EVA foam projects. Epoxy resin, contact adhesive, and craft glues designed specifically for foam materials are all excellent choices. These adhesives are formulated to provide a strong bond while still allowing for the necessary flexibility that EVA foam demands.

Two-Part Epoxy: Strong and Durable Bond with Flexibility

Look no further. In this blog post, we’ll explore the advantages of using two-part epoxy for bonding EVA foam. Whether you’re an avid crafter, a DIY enthusiast, or a professional in need of a reliable adhesive, two-part epoxy is here to save the day.

Super Strength:

When it comes to strength, two-part epoxy is a force to be reckoned with. Once it cures, it forms a bond that can handle heavy loads and stresses. Picture your industrial projects or intricate crafts standing tall and strong, thanks to the unyielding grip of two-part epoxy. No more worries about your creations falling apart.

Flexibility Matters:

Unlike some glues that become brittle over time, epoxy maintains its flexibility even after curing. This is crucial when working with EVA foam, a material that bends and flexes. With epoxy, your bonded joints can move with the foam, preventing cracks or breaks in the adhesive. So go ahead and twist, turn, and bend your creations without fear.

Waterproof Wonder:

EVA foam projects often come into contact with water or other liquids. Thankfully, two-part epoxy provides a waterproof bond. Once cured, it creates a barrier that keeps moisture at bay, protecting both the adhesive and the foam. So whether you’re working on marine or outdoor projects, rest assured that your bond will stay strong even in wet conditions.

How to Use It:

Using two-part epoxy on EVA foam is straightforward but requires careful attention to detail. Start by following the manufacturer’s instructions for mixing the resin and hardener in specific ratios. Apply the mixture to the surfaces to be bonded and allow it to cure for the designated time. Remember to provide adequate ventilation during the curing process as some epoxy formulations may release fumes.

Limitations to Consider:

While two-part epoxy offers numerous advantages, it’s essential to consider its limitations. The curing time can be a drawback for projects that require quick assembly or immediate use. Additionally, the mixing process requires precise measurements and thorough mixing. However, with a little patience and attention to detail, the results will be well worth it.

Other Types of Glues Suitable for Bonding EVA Foam

Well, choosing the right glue is crucial for ensuring the longevity and durability of your creations. In this blog post, we’ll explore the various types of glues suitable for bonding EVA foam, their advantages, and limitations. Let’s dive in.

Contact Cement: The Bonding Champion.

Contact cement is often considered the go-to glue for bonding EVA foam. It forms a strong bond by creating a chemical reaction when its solvent evaporates. Contact cement offers excellent flexibility and is resistant to water, making it perfect for long-lasting bonds on EVA foam.

EVA Foam Glue: A Tailored Solution

Some manufacturers produce specialized glues designed specifically for bonding EVA foam. These glues are formulated to provide optimal adhesion and flexibility for EVA foam applications. They come in spray or brush-on form, making application a breeze.

Hot Glue: Quick and Convenient

Hot glue guns are a staple in many crafts and DIY projects, including those involving EVA foam. Hot glue can create a quick bond, but it may not be as durable or flexible as other options. However, it can still be suitable for certain EVA foam projects where flexibility is not critical.

Super Glue: Instant Bonding Power

Super glue, also known as cyanoacrylate adhesive, forms an instant bond. It can be effective for small EVA foam pieces or quick repairs. However, super glue may not provide the same level of flexibility as other options, so consider your project requirements carefully.

Two-Part Epoxy: Strong and Reliable

Two-part epoxy adhesives consist of a resin and hardener that must be mixed together before application. Once mixed, they provide a strong and durable bond. When choosing epoxy for EVA foam, ensure it is flexible and designed specifically for this purpose.

ZbB2_pp24m8″ >

Conclusion

When it comes to bonding EVA foam, choosing the right glue is crucial. After careful research and testing, we have determined that the best glue for EVA foam is a contact cement adhesive. Its strong and durable bond ensures that your foam projects will stay intact for a long time.

Contact cement adhesive has several advantages over other glues when it comes to working with EVA foam. Its ability to create an instant bond eliminates the need for clamping or waiting for the glue to dry. This saves you valuable time and allows you to move on with your project without any delays.

Furthermore, contact cement adhesive forms a flexible bond that can withstand bending and stretching, making it ideal for applications where the foam needs to retain its shape. Whether you’re crafting costumes, cosplay props, or custom-made accessories, this glue will ensure that your creations maintain their structural integrity.

Another benefit of using contact cement adhesive is its resistance to heat and moisture. This makes it suitable for outdoor projects or items that may come into contact with water. You can rest assured knowing that your glued EVA foam pieces won’t weaken or detach when exposed to different environmental conditions.

In addition to its performance, contact cement adhesive is also easy to work with. Applying a thin layer of adhesive on both surfaces of the foam, allowing it to dry until tacky, and then pressing the surfaces together firmly creates a strong bond. The process is straightforward and doesn’t require any specialized tools or techniques.

To summarize, when it comes to gluing EVA foam, contact cement adhesive is undoubtedly the best choice. Its instant bonding capabilities, flexibility, resistance to heat and moisture, as well as ease of use make it the go-to glue for all your foam crafting needs.