Books are more than just ink on paper; they’re portals to new worlds, gateways to knowledge, and cherished companions. But what keeps these literary treasures intact? The answer lies in the glue that binds them together. With countless adhesives vying for attention, finding the best glue can be overwhelming. Fear not. In this article, we’ll reveal the ultimate glue that guarantees a bond so strong, your books will stand the test of time.

When it comes to choosing a binding glue, flexibility, strength, and longevity are key considerations. You’ve likely heard of popular options like PVA and EVA glues – they’re commonly used in bookbinding. While both have their merits, there’s one glue that outshines them all: enter PUR (polyurethane reactive) glue.

Why is PUR glue the crème de la crème? It boasts unparalleled strength and flexibility, ensuring your book’s pages stay put while still allowing for easy flipping. Unlike its counterparts, PUR creates a molecular bond with paper fibers, resulting in an unbreakable connection that won’t budge over time. Plus, it can weather extreme temperatures without breaking a sweat.

But here’s the catch – using PUR glue requires specialized equipment and techniques that may pose challenges for DIY bookbinders or those lacking professional tools. However, don’t let that deter you. The end result is worth every ounce of effort. Books bound with PUR glue boast unmatched durability and resilience.

In our upcoming articles, we’ll dive deeper into the application process and explore alternative options for various bookbinding projects. So buckle up as we embark on an exhilarating journey to uncover the secrets behind achieving flawlessly bound books through the wise choice of the ultimate binding adhesive. Get ready to make your books last a lifetime.

Polyvinyl Acetate (PVA) Glue: Advantages and Disadvantages

Contents

- 1 Polyvinyl Acetate (PVA) Glue: Advantages and Disadvantages

- 2 Animal Glue: Benefits and Challenges

- 3 Epoxy Resin Glue: Pros and Cons

- 4 Cyanoacrylate Glue: Strengths and Weaknesses

- 5 Factors to Consider When Choosing the Right Glue for Bindings

- 6 Advantages of Using PVA, Animal, Epoxy Resin, and Cyanoacrylate Glues

- 7 Common Mistakes to Avoid When Selecting a Binding Glue

- 8 Tips for Applying Different Types of Binding Glues

- 9 Conclusion

In the world of binding projects, finding the right glue is crucial for achieving a strong and durable bond. Among the many options available, Polyvinyl Acetate (PVA) glue stands out as a popular choice due to its versatility and ease of use. In this article, we will explore the advantages and disadvantages of using PVA glue for binding purposes, allowing you to make an informed decision for your next project.

Advantages of PVA Glue:

- Strong Bond: PVA glue excels at creating a robust bond between various materials, including paper, cardboard, fabric, wood, and certain plastics. This makes it suitable for a wide range of binding projects, from intricate crafts to sturdy woodworking.

- Quick Drying Time: Unlike other glues that may take hours to dry, PVA glue sets relatively fast, usually within 15-30 minutes. This allows for efficient workflow, particularly when working on multiple binding projects simultaneously.

- Non-Toxic and Easy Cleanup: PVA glue is generally safe to use as it is non-toxic when dry. This makes it ideal for projects involving children or when working in enclosed spaces. Furthermore, its water-soluble nature enables easy cleanup with just water, ensuring a mess-free and convenient working environment.

Disadvantages of PVA Glue:

- Limited Water Resistance: While PVA glue offers excellent adhesion on various materials, it lacks strong resistance against moisture or water exposure. Over time, the bond created by PVA glue may weaken or dissolve when faced with water or high humidity. Therefore, it may not be the best choice for projects requiring long-term durability in wet environments.

- Susceptibility to Heat: PVA glue is sensitive to heat and can weaken or break when subjected to high temperatures. This makes it less suitable for bindings that may come into contact with heat sources, such as books or documents that might be exposed to direct sunlight or hot environments.

- Potential Yellowing Over Time: Over an extended period, PVA glue may start to yellow or darken, especially when exposed to direct sunlight or UV radiation. This can affect the aesthetics of light-colored materials, so it’s important to consider this factor when choosing PVA glue for your bindings.

Animal Glue: Benefits and Challenges

If you’re a bookbinding enthusiast or just someone curious about the world of adhesives, you’ve probably come across animal glue. Also known as hide glue, this traditional adhesive has been used for centuries in various applications, including bookbinding. In this article, we’ll explore the advantages and disadvantages of using animal glue, so you can gain a better understanding of its unique properties.

Let’s start with the benefits. One of the key advantages of animal glue is its strong bond. It has excellent adhesion properties, ensuring that book pages stay securely in place even with frequent use. This is particularly important for bindings that need to withstand the test of time, such as antique books or valuable manuscripts. The strong bond created by animal glue helps to prevent pages from becoming loose or detached, ensuring the longevity of the book.

Another benefit of animal glue is its reversibility. Unlike some modern synthetic adhesives, animal glue can be easily reversed if needed. This means that if repairs or changes are required in the future, the binding can be disassembled without causing damage to the pages or the spine. This reversibility is highly valued by conservators and collectors who prioritize the preservation of historical books and manuscripts.

In addition to its functional benefits, animal glue also offers a natural and traditional appeal to bookbinding. Many enthusiasts and artisans appreciate the authenticity and historical significance that comes with using animal glue. Additionally, animal glue is often favored for its compatibility with other traditional binding materials, such as parchment or vellum. Its compatibility with these materials ensures a cohesive and durable binding.

However, like any other adhesive, animal glue has its challenges. One of the main drawbacks is its sensitivity to temperature and humidity changes. Animal glue can soften or become brittle under extreme conditions, potentially leading to damage to the binding. To minimize this risk, it is important to store books bound with animal glue in a controlled environment.

Another challenge associated with animal glue is its preparation process. Animal glue typically comes in solid granules or flakes and needs to be dissolved in water prior to use. This requires careful measurement and proper temperature control to achieve the desired consistency. Additionally, animal glue has a relatively short working time once it is prepared, which means that bookbinders need to work efficiently to ensure a successful binding process.

In conclusion, animal glue offers several benefits for bookbinding, including its strong bond, reversibility, and compatibility with traditional materials. It appeals to those who value authenticity and historical significance in their bindings. However, it is important to consider the challenges posed by temperature sensitivity and the preparation process. Overall, animal glue remains a popular choice for bindings due to its unique properties and long-standing tradition in bookbinding practices.

Epoxy Resin Glue: Pros and Cons

Look no further than epoxy resin glue. This two-part adhesive offers a range of benefits, including incredible strength, versatility, and the ability to effortlessly fill gaps. However, before you dive into your next binding project, it’s crucial to weigh these advantages against a couple of potential drawbacks.

The Pros:

Unrivaled Strength:

Epoxy resin glue is renowned for its exceptional bonding strength. It creates a rock-solid bond that can withstand heat, chemicals, and moisture. This makes it the perfect choice for bindings that need to endure harsh conditions or frequent handling.

Limitless Versatility:

Wood, metal, plastic, glass – you name it, epoxy resin glue can handle it. Its ability to adhere to a wide range of materials makes it suitable for various types of bindings. From furniture repairs to securing metal brackets, epoxy resin glue is up to the task.

Gap-Filling Wizardry:

With its thick consistency, epoxy resin glue excels at filling in gaps and cracks in binding materials. This not only creates a stronger bond but also provides extra structural support. It’s particularly useful when dealing with uneven surfaces or repairing damaged bindings.

Patience is a Virtue:

No need to rush with epoxy resin glue. It provides you with ample time to position and adjust the binding before it sets. This is especially valuable for complex or intricate projects that require precise alignment. Take your time – epoxy resin glue has got your back.

The Cons:

Curing Takes Time:

One drawback of epoxy resin glue is its longer curing time compared to other adhesives. Depending on the specific product and conditions, it may take several hours or even overnight for the adhesive to fully cure. If you’re working on a time-sensitive project, this could be a potential inconvenience.

Mixing Mastery:

Epoxy resin glue is a two-part adhesive that demands careful mixing of the resin and hardener components. Accurate measurements and thorough blending are essential for proper curing and optimal bond strength. Rushing or improper mixing can result in weak bonds or incomplete curing.

Safety First:

It’s important to note that epoxy resin glue contains chemicals that can be harmful if not handled properly. To minimize any potential health risks, follow safety precautions such as wearing gloves and working in a well-ventilated area.

Cyanoacrylate Glue: Strengths and Weaknesses

Embarking on a binding project can be as challenging as selecting the perfect book to read on a rainy day. In this blog post, we will delve into the strengths and weaknesses of using cyanoacrylate glue, also known as super glue, for bindings. So sit back, relax, and let’s explore the world of adhesive possibilities.

Strengths:

- Lightning-fast bonding: Cyanoacrylate glue is like the Flash of adhesives. It forms an almost instantaneous bond between binding materials, saving you valuable time and allowing you to proceed with your project without delay.

- Unmatched versatility: Like a chameleon, cyanoacrylate glue effortlessly adapts to various binding materials. Whether you’re working with paper, cardboard, leather, fabric, or certain plastics, this adhesive has your back.

- Herculean adhesive properties: When it comes to strength, cyanoacrylate glue is like the Hulk. It creates a bond that can withstand moderate stress and strain, ensuring that your bindings remain secure for the long haul.

- Tidy application: Say goodbye to sticky fingers and messy workstations. Cyanoacrylate glue comes in small bottles with precision applicators, making it easy to apply just the right amount without creating a sticky situation.

Weaknesses:

- Brittle bond: While cyanoacrylate glue is robust, it can be a bit like Mr. Glass from “Unbreakable.” The bond it creates is more prone to cracking or breaking over time, especially in situations where flexibility is required.

- Limited gap-filling ability: This adhesive isn’t the best problem solver when it comes to uneven surfaces or large gaps. It prefers tight fits like puzzle pieces and may not provide optimal results if your binding materials have irregularities.

- Moisture sensitivity: Cyanoacrylate glue is like a delicate flower when it comes to moisture. It’s crucial to ensure that your binding materials are dry and free from moisture before applying the glue. High humidity levels can also affect its shelf life and performance.

- Potential health hazards: Remember, with great power comes great responsibility. Cyanoacrylate glue emits fumes that can be irritating to the eyes, nose, and throat. So be sure to work in a well-ventilated area or don the appropriate protective gear to keep yourself safe.

Factors to Consider When Choosing the Right Glue for Bindings

Choosing the right glue for bindings is crucial to ensure that your books, journals, or other bound materials are sturdy and long-lasting. With so many options available, it can be overwhelming to determine which glue is best suited for your project. In this article, we will explore the key factors to consider when selecting the best glue for binding materials.

- Bond Strength: Look for glues specifically designed for binding applications that offer a strong and secure bond to keep the pages in place.

- Flexibility: Choose a glue that can maintain its bond even when the book is flexed or opened widely, preventing loose pages or cracked bindings over time.

- Drying Time: Find a balance between drying time and bond strength based on your project requirements. Fast-drying glues allow you to move quickly, but may have weaker bonds compared to slower drying options.

- pH Level: Opt for pH-neutral or acid-free glue to ensure longevity and preservation of your bindings, preventing discoloration or weakening of the pages over time.

- Application Method: Consider how you plan to apply the glue. Liquid glues allow for precise placement with brushes or applicators, while stick or tape glues offer convenience and ease of use for smaller projects.

- Compatibility: Ensure the glue you choose is compatible with the materials you are binding together. Different materials may require specific types of glue.

- Longevity: If durability is important, choose a glue known for its ability to withstand the test of time.

Now, let’s explore the different types of glues available for binding materials:

- PVA Glue: Offers a strong bond, dries clear, and is flexible when dry. Available in liquid and gel forms.

- Epoxy: Provides excellent bond strength and durability, ideal for materials requiring a strong hold like metal or plastic covers.

- Hot Glue: Quick and temporary bonding option, but may not be suitable for long-term use or materials needing flexibility.

- Acrylic Adhesive: Offers a strong bond and resistance to moisture and chemicals, commonly used in industrial bookbinding.

Advantages of Using PVA, Animal, Epoxy Resin, and Cyanoacrylate Glues

In this article, we will explore the unique advantages of using PVA glue, animal glue, epoxy resin, and cyanoacrylate glue for all your binding needs.

Let’s start with PVA glue, the jack-of-all-trades adhesive. This versatile glue is a favorite among bookbinders for a reason. It forms a strong bond with various materials like paper, cardboard, and fabric. Plus, it dries clear, so your bindings will look flawless. Not only is it strong, but it’s also non-toxic and water-soluble, making it safe and easy to clean up.

If you’re a fan of traditional methods, animal glue might be the perfect choice for you. It has stood the test of time in bookbinding for centuries. What makes it so special? Animal glue offers excellent adhesion strength, ensuring your bindings won’t budge. The best part? It’s reversible. So if you ever need to disassemble and reassemble your books, animal glue can be softened and reactivated with moisture. It also remains flexible when dry, allowing your bound materials to expand or contract without damage.

For heavy-duty applications that demand durability, epoxy resin is the go-to adhesive. This super-strong glue is known for its exceptional resistance to moisture, solvents, and heat. It’s perfect for materials that may face harsh conditions or frequent handling. And if you have uneven surfaces or gaps to fill, epoxy resin is your best friend. It bonds effectively and provides a strong connection even when things don’t fit perfectly.

Last but not least, we have cyanoacrylate glue, also known as super glue. This fast-acting adhesive forms an instant bond within seconds. If you need immediate results or have small binding projects, cyanoacrylate glue is your secret weapon. It works on various materials like plastic, metal, and wood and is resistant to moisture and temperature fluctuations.

Now that you know the advantages of each type of glue, how do you choose the right one? Consider the materials you’re working with, the desired strength and flexibility of your binding, and any specific conditions your bindings may face. And remember, a successful application is all about preparation. Clean and dry your surfaces, apply the glue evenly, and give it time to dry or cure properly.

Common Mistakes to Avoid When Selecting a Binding Glue

Today, we are delving into the world of binding glues and uncovering the common mistakes to avoid when selecting the perfect glue for your projects. So, grab a cup of coffee and prepare to glean some invaluable tips.

First and foremost, selecting the right binding glue is essential to ensure a robust and long-lasting bond. Choosing the wrong glue can lead to messy, weak, or even failed bindings. And let’s be honest, nobody wants that. So, let’s dive into the mistakes you should steer clear of.

- Mistake #1: Ignoring the material. Different materials require different types of glue. Whether you’re working with paper, cardboard, leather, or fabric, each material has unique adhesive needs. To achieve optimal adhesion, make sure to choose a glue specifically designed for the material you are working with.

- Mistake #2: Opting for a weak glue. Bindings often face stress and pressure. Selecting a glue with a strong bond is crucial to ensure your bindings stay intact over time. Using a weak glue can lead to loose or falling-apart bindings that will leave you feeling frustrated and disappointed.

- Mistake #3: Using too much or too little glue. Applying an excessive amount of glue can result in a messy appearance as it seeps through the pages. Conversely, using too little glue may not provide enough adhesive strength for a secure bind. Follow the manufacturer’s instructions and apply the appropriate amount of glue for a flawless result.

- Mistake #4: Rushing the drying process. Patience is key here. Failing to allow sufficient drying time can weaken the adhesive bond and compromise durability. Take heed of the instructions provided and give your glue ample time to dry and cure properly.

- Mistake #5: Neglecting environmental factors. Some glues may not fare well in high humidity or extreme temperatures. Consider where your bindings will be stored or used and select a glue that can withstand those conditions. Don’t let environmental factors sabotage the longevity of your bindings.

By avoiding these common mistakes, you can ensure that your bindings are not only strong and durable but also visually pleasing. Take the time to research and choose the right glue for your specific needs. Trust me, it’s worth the effort.

Tips for Applying Different Types of Binding Glues

Choosing the right glue is essential for creating strong and lasting bindings in bookbinding projects. With various types of binding glues available, each with its own unique properties, it’s important to understand how to apply them effectively. In this article, we will explore different types of binding glues and provide tips for their application, ensuring successful and durable bindings.

PVA Glue:

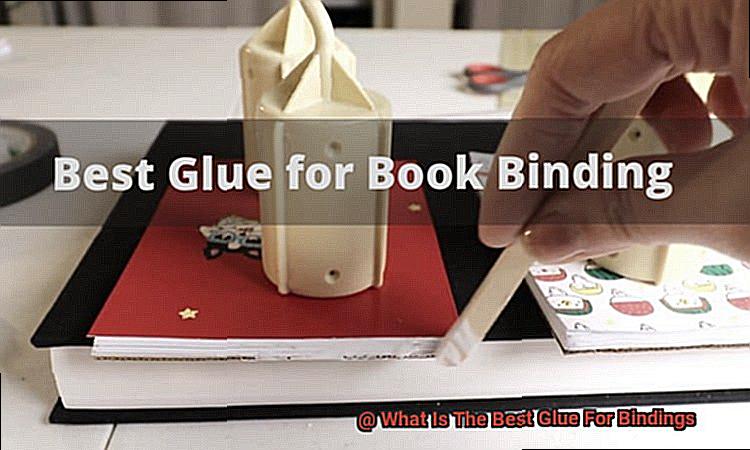

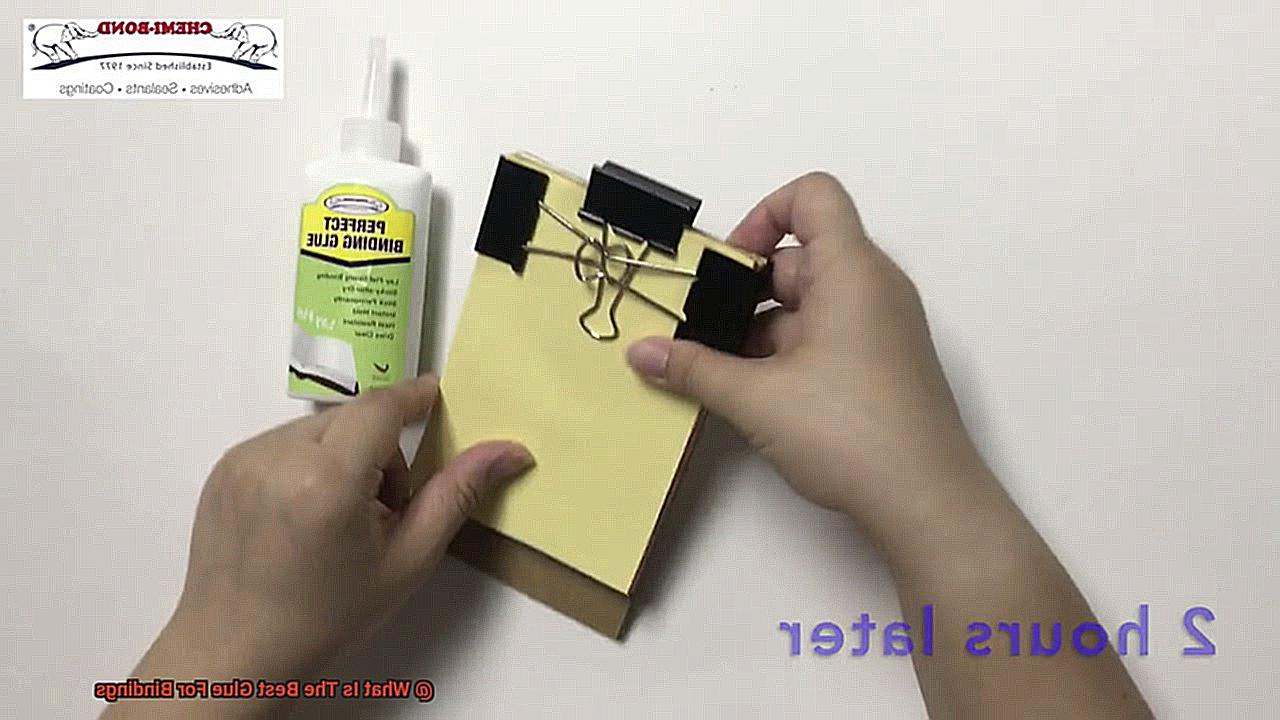

PVA glue, also known as white glue or wood glue, is a popular choice due to its water-based composition and strong bonding capabilities. To apply PVA glue, evenly spread a layer on both surfaces using a brush or roller. Firmly press the surfaces together and use clamps or weights to hold them in place until the glue dries completely.

Hot Glue:

Hot glue is a fast and strong adhesive suitable for various materials like fabric, plastic, and wood. When applying hot glue, work swiftly as it dries rapidly. Apply a thin and even layer on one surface and immediately press the two surfaces together. Be cautious not to overapply hot glue, as it can create a messy and bulky binding.

Epoxy Glue:

For heavy-duty bindings or materials requiring extra strength, epoxy glue is an excellent choice. Follow the manufacturer’s instructions carefully when applying epoxy glue. Mix equal amounts of resin and hardener on a clean surface, apply the mixture to the surfaces needing bonding, and press them firmly together. Secure the bond with clamps or weights until the epoxy cures completely.

Fabric Glue:

Designed specifically for bonding fabric materials, fabric glue should be applied sparingly on the edges or seams of the fabric pieces to be bonded. Firmly press the pieces together and allow the glue to dry completely before handling the fabric.

Rubber Cement:

Rubber cement is a unique type of adhesive that remains tacky even after drying, making it suitable for temporary bindings or repositionable projects. Apply a thin layer of rubber cement to the surfaces needing bonding and press them together firmly. Allow the glue to dry completely before handling the bound item.

Conclusion

When it comes to finding the best glue for bindings, there are a few key factors to consider. You want a glue that is strong, durable, and long-lasting. It should be able to withstand wear and tear, as well as temperature changes. Additionally, it should dry clear and not leave any residue or marks on the pages.

One of the top contenders in this category is bookbinding glue. This type of glue is specifically designed for binding purposes and offers excellent adhesion. It is flexible enough to allow for easy opening and closing of the book without compromising its strength.

Another popular option is PVA glue (polyvinyl acetate). PVA glues are known for their versatility and ability to bond different materials together effectively. They dry quickly and provide a strong bond, making them suitable for binding various types of books.

For those who prefer a more traditional approach, animal-based glues such as hide glue or bone glue can also be used for bindings. These glues have been used in bookbinding for centuries and offer good adhesion properties.

In terms of application, it is important to apply the glue evenly along the spine of the book using a brush or roller applicator. Excess glue should be wiped away before it dries to ensure a clean finish.

Ultimately, the best glue for bindings will depend on your specific needs and preferences. It’s always a good idea to test different options on sample pages before committing to one type of glue. Remember that proper preparation and technique are just as important as choosing the right adhesive.