Do you ever wonder if wood glue is strong enough to hold a box together?

Well, I’m here to tell you that it’s not a trivial concern. As someone who loves woodworking, I’ve spent countless hours experimenting with different adhesives to find the answer.

And today, I’m excited to share my expertise with you. In this blog post, we’ll explore the different types of wood glue and how to apply them properly.

So, let’s dive into the world of wood glue strength and discover just how tough this adhesive can be.

Wood Glue

Contents

- 1 Wood Glue

- 2 Types of Wood Glue

- 3 Factors to Consider When Choosing Wood Glue for Box Construction

- 4 Quality and Strength of Different Types of Wood Glue

- 5 Proper Application Technique for Maximum Bonding Strength

- 6 Other Factors That Impact the Strength of the Bond

- 7 Design and Construction of the Box Matter Too

- 8 Reinforcing Joints with Additional Methods

- 9 Conclusion

Wood glue is a remarkable adhesive that boasts a plethora of benefits when it comes to bonding wood surfaces together. Crafted specifically for woodworking projects, furniture making, and carpentry, this versatile adhesive is an essential tool in the arsenal of every woodworker and carpenter.

The beauty of wood glue lies in its ability to create a bond stronger than the wood itself. It achieves this through the magic of chemical bonding, as it penetrates the pores of the wood and forms a strong connection with the cellulose fibers present within. This bond is not to be taken lightly, as it can withstand the test of time and endure even the harshest conditions.

When it comes to choosing the right wood glue, there are various options available. White or yellow polyvinyl acetate (PVA) glues are commonly used for general woodworking applications and offer excellent strength. Epoxy glues bring exceptional durability and strength to the table, but they require careful mixing and curing time. For those seeking waterproof properties and the ability to bond different materials, polyurethane glues are the go-to choice.

While wood glue has commendable strength, other factors must be considered as well. The type of wood being used, the quality of the glue, and the application technique all contribute to the overall bond strength. Additionally, it’s important to take into account the design and construction of the project. If weak points or multiple joints are present, reinforcing with screws or nails may be necessary.

Types of Wood Glue

Wood glue is an essential adhesive for box-making projects, and there are various types available, each with its own advantages and disadvantages. Here are the different types of wood glue commonly used for box-making projects:

PVA Glue

Polyvinyl acetate (PVA) glue is the most commonly used wood glue for box-making projects. It offers a strong bond and is versatile in its applications. PVA glue is easy to clean up and non-toxic, making it safe to use. It dries clear, which is ideal when the glue may be visible in the final project. PVA glue also comes in different formulations, such as regular, waterproof, and extended open time, providing options based on specific project requirements.

Polyurethane Glue

Polyurethane glue, like Gorilla Glue, is another popular option for bonding wood in box-making projects. It forms a strong bond that is resistant to water, heat, and solvents. This type of glue expands as it cures, filling gaps and creating a strong joint. However, it requires moisture to activate the curing process, so dampening the wood surfaces before applying the glue is necessary.

Hide Glue

Hide glue is a traditional adhesive made from animal collagen. It has several advantages, including a long open time that allows for adjustments during assembly. Hide glue also has excellent reversibility, meaning glued joints can be easily disassembled by applying heat and moisture. However, hide glue requires special preparation and application techniques compared to modern wood glues.

Epoxy Glue: Epoxy glue consists of two components: resin and hardener.

Cyanoacrylate Glue

Cyanoacrylate glue, commonly known as super glue or CA glue, is a fast-setting adhesive that forms an instant bond. It works well for small repairs and bonding small wooden parts together. However, it may not be suitable for larger woodworking projects like box construction due to its limited gap-filling properties and brittleness.

Factors to Consider When Choosing Wood Glue for Box Construction

Choosing the right wood glue for box construction requires careful consideration of several factors. Here are the key factors to keep in mind:

- Type of Wood: Different types of wood have different porosities and absorbencies. Some woods, like oak or ash, have open pores that readily absorb glue, while others, such as maple or birch, have closed pores that require a specific type of glue. It’s crucial to select a wood glue that is compatible with the type of wood you are working with to ensure a strong bond.

- Size and Weight of the Box: The size and weight of the box play a significant role in determining the appropriate wood glue. For smaller or lighter boxes made from materials like plywood or particleboard, a standard wood glue may suffice. However, for larger or heavy-duty boxes, it is advisable to use a stronger adhesive, such as epoxy or polyurethane glue, which offer superior bonding strength.

- Intended Use of the Box: Consider how the box will be used. If it will be primarily for decorative purposes or light storage, a regular wood glue may be suitable. However, if the box will be subjected to frequent movement or heavy loads, like a toolbox or storage chest, it is essential to choose a wood glue that can withstand these conditions.

- Drying Time: Wood glues vary in their drying time, which can range from as quick as 30 minutes to several hours or even overnight. Consider your project timeline and choose a wood glue that aligns with your needs. Additionally, some glues require clamping during the drying process, so factor in the time needed for clamping as well.

- Water Resistance: If your box is likely to be exposed to moisture or humidity, selecting a water-resistant or waterproof wood glue is crucial. These types of glues provide added protection against moisture-related damage and ensure the longevity of your box.

- Personal Preference: Finally, personal preference and familiarity with a specific brand or type of wood glue can influence your decision. If you have had success with a particular glue in the past and trust its performance, it may be worth sticking with what you know. Nevertheless, it’s always beneficial to explore different options and consider the specific requirements of your box construction project.

Quality and Strength of Different Types of Wood Glue

Yellow Woodworking Glue:

Yellow woodworking glue, also known as carpenter’s glue or aliphatic resin glue, is a popular choice for woodworking projects due to its strong bond and ability to withstand stress and pressure. This type of glue forms a tight and durable bond that can hold even under heavy loads. It is also water-resistant when dry, making it suitable for both indoor and outdoor applications. Yellow woodworking glue is easy to work with and provides excellent adhesion, making it a go-to option for many woodworkers.

PVA Glue:

PVA glue, often referred to as white glue or school glue, is another commonly used wood adhesive. It is non-toxic and easy to use, making it popular among DIY enthusiasts and hobbyists. PVA glue forms a strong bond by penetrating into the wood fibers and creating a chemical bond as it dries. While not as strong as yellow woodworking glue, PVA glue is suitable for most woodworking projects that do not require heavy-duty strength. It is ideal for bonding smaller pieces of wood together or for general crafts and projects.

Epoxy Glue:

Epoxy glue is known for its exceptional strength and durability. It consists of two parts – a resin and a hardener – that must be mixed together before application. Once mixed, epoxy glue creates a strong chemical bond between wood surfaces. This type of glue is ideal for heavy-duty applications such as furniture construction or bonding different types of materials together. Epoxy glue provides superior strength and can withstand heavy loads and extreme conditions. However, it requires longer curing times compared to other types of wood glue.

Polyurethane Glue:

Polyurethane glue, also known as expanding foam glue, offers excellent water resistance and can bond well with different materials, including wood. As it cures, it expands, filling gaps and creating a strong bond.

Polyurethane glue is particularly useful for projects that require a waterproof or weather-resistant bond. However, it can be messy to work with and requires careful application. Despite its messiness, polyurethane glue provides a strong and reliable bond that can withstand various conditions.

Proper Application Technique for Maximum Bonding Strength

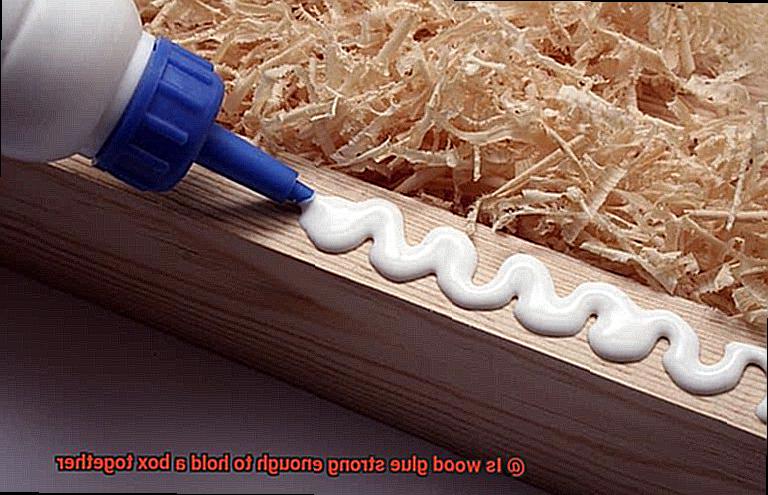

The proper application technique for achieving maximum bonding strength involves several key steps. First, surface preparation is crucial. Before applying wood glue, make sure the surfaces to be bonded are clean, dry, and free from any dust, debris, or grease. This can be done by wiping the surfaces with a clean cloth or using a mild cleaning solution if necessary. Additionally, ensure that the surfaces fit together tightly without any gaps.

Applying the right amount of glue is also essential. It is important to apply an adequate amount of wood glue for maximum bonding strength. Too little glue may result in weak bonding, while too much glue can lead to excessive squeeze-out and messy joints. To achieve the perfect amount, apply a thin, even layer of glue to both surfaces using a brush or a small roller. Spread the glue evenly across the entire surface, covering all areas that will be bonded.

Once the glue is applied, clamping and pressure are necessary for a strong bond. Clamping the wood pieces firmly together ensures that the glue spreads evenly and makes proper contact with both surfaces. The amount of pressure required depends on the type of wood and the size of the project. In general, use clamps or weights to provide consistent pressure across the entire joint.

Allow sufficient drying and curing time for the bond to reach maximum strength. The drying time can vary depending on factors such as temperature, humidity, and the type of wood glue used. Consult the product label or manufacturer’s instructions for recommended drying and curing times. It is crucial to avoid applying excessive force or stress on the bonded joint before it has fully cured.

Finally, finishing and sealing the project is important to protect the glued joint and enhance its overall strength. Once the wood glue has dried and cured, sand the surface smooth and apply a suitable wood finish or sealant. Allow it to dry thoroughly to add an extra layer of protection and prevent moisture from weakening the bond over time.

Other Factors That Impact the Strength of the Bond

When it comes to the strength of a bond using wood glue, there are several factors that come into play. First and foremost, the quality of the wood glue itself is crucial. Opting for a high-quality wood glue specifically designed for bonding wood can make a significant difference. Cheaper glues may lack the necessary adhesive properties, resulting in weaker bonds.

The technique used to apply the glue is equally important. It’s essential to apply an even layer of glue to both surfaces being bonded, ensuring full coverage. Uneven application or leaving gaps can weaken the bond, so attention to detail is key.

Curing time is another critical factor. Allowing the glue sufficient time to cure is crucial for achieving a strong bond. Rushing the process by moving or stressing the glued pieces before the glue has fully cured can compromise the strength of the bond.

The moisture content of the wood being bonded also plays a role. Wood that is too dry or too wet may not bond as effectively with wood glue. Therefore, checking and ensuring an appropriate moisture level in the wood before applying the glue is essential.

The design and construction of the joints in the box also impact bond strength. Strong, well-fitting joints provide more surface area for bonding and increase overall strength.

Considerations should also be given to the age and storage conditions of the wood glue itself. Wood glue has a shelf life, so using expired or improperly stored glue can result in weaker bonds. Checking expiration dates and storing glue in a cool, dry place is critical.

Design and Construction of the Box Matter Too

When it comes to constructing a box, you might think that wood glue alone is enough to hold it together. But, in reality, the design and construction of the box are crucial factors that can make or break its strength. So, let’s dive into the details and find out why these factors matter so much.

First and foremost, the type of joint used in constructing the box plays a significant role in determining the strength of the glue joint. There are several common joints to consider, each with its own advantages and considerations. Let’s take a closer look:

Butt Joints:

These joints are simple and straightforward, where two pieces of wood are joined together by gluing their ends. However, relying solely on wood glue may not provide enough strength for long-term durability. To reinforce butt joints, it’s often necessary to use nails or screws.

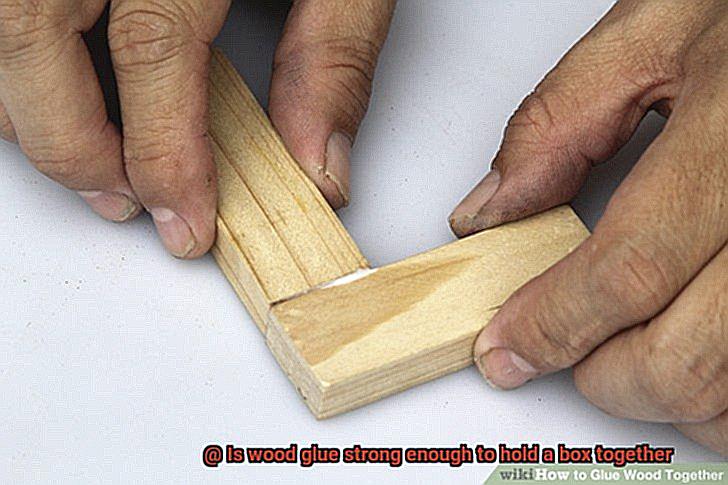

Miter Joints:

If you’re looking for a stronger bond, miter joints are an excellent choice. They provide more surface area for the glue to adhere to, thanks to the angled cuts that create a larger contact area. This makes miter joints ideal for gluing boxes together.

Dovetail Joints:

When it comes to both mechanical and adhesive strength, dovetail joints are hard to beat. These interlocking joints offer exceptional stability and durability and are commonly used in high-quality furniture and boxes.

Finger Joints:

Similar to dovetail joints but easier to make, finger joints are another popular choice for box construction. They provide a large surface area for glue to adhere to, ensuring a strong bond.

In addition to joint design, the surface area and wood quality also play vital roles in box construction. A well-designed and properly constructed box will have joints that maximize the contact area between the pieces of wood.

This increased surface area allows for better adhesion of the wood glue, resulting in a stronger bond. Moreover, the quality of the wood used is crucial. Solid hardwoods like oak, maple, and walnut tend to have better gluing properties than softwoods like pine or fir.

But it doesn’t stop there. Proper preparation and clamping are equally important for a strong bond. Before applying glue, make sure the wood surfaces are clean, dry, and free from any contaminants that may hinder adhesion.

And when clamping the joints together, exerting even pressure across the joint is essential. This will help squeeze out excess glue and create a tight bond.

Lastly, don’t rush the drying and curing process. Allowing sufficient time for the glue to dry and cure is crucial for achieving optimal strength.

Follow the manufacturer’s instructions regarding drying time to ensure the bond reaches its maximum potential. Remember, patience is key when it comes to glue.

Reinforcing Joints with Additional Methods

Reinforcing joints with additional methods is a crucial step in ensuring the strength and longevity of wooden boxes. While wood glue alone can provide a solid hold, incorporating reinforcement techniques can take the stability to new heights.

One method of reinforcing joints is through the use of mechanical fasteners, such as screws or nails. These sturdy components secure the joints tightly, adding extra strength and security. When using screws, it’s important to pre-drill pilot holes to prevent the wood from splitting. Nails, on the other hand, should be driven in at an angle to maximize their holding power.

Another effective technique for reinforcing joints is the use of dowels or biscuits. Dowels are cylindrical wooden rods that are meticulously inserted into pre-drilled holes in the joint. Once in place, they are often glued to provide additional strength and stability.

Biscuits, on the other hand, are small oval-shaped pieces of compressed wood that fit neatly into matching slots cut into the joint. Like dowels, biscuits are also glued in place to reinforce the joint.

In some instances, metal brackets or corner braces can be employed to reinforce joints. These durable metal components are typically secured with screws or nails, delivering added support and stability to the joints. With a range of sizes and shapes available, brackets and braces can be tailored to fit different joint configurations.

For heavy-duty applications or when an extra layer of reinforcement is desired, wood splines or keys can be used. Splines are thin strips of wood that are carefully inserted into a groove cut across the joint.

Once securely placed, they are glued to create a robust bond between the two pieces of wood. Keys, similar to splines but with a wedge-like shape, are inserted into a slot cut on one side of the joint and then driven in with a mallet to create a tight fit.

While these additional methods undoubtedly enhance joint strength, it’s important not to overlook the significance of the wood glue used. Opting for a high-quality wood glue specifically designed for bonding wood is vital to ensure a strong and durable hold. Additionally, proper surface preparation, including ensuring clean and dry surfaces, is imperative for optimal bonding.

gPsBLealwwY” >

Conclusion

In conclusion, wood glue is indeed strong enough to hold a box together.

Its adhesive properties create a bond that can withstand the stresses and strains of everyday use. Whether you’re building a small jewelry box or a sturdy storage container, wood glue provides the necessary strength and durability.

So rest assured, when it comes to assembling your wooden creations, wood glue is up to the task.