Are you ready to tackle a plumbing project but unsure if ABS pipe can be connected to PVC? You’re not alone – this is one of the most frequently asked questions in the world of DIY plumbing. The answer isn’t a simple “yes” or “no,” as it depends on several factors.

ABS and PVC pipes may look alike, but they have different properties and chemical compositions. This makes connecting them a bit challenging, and it’s essential to understand the nuances before attempting it.

In this post, we’ll take a deep dive into the world of ABS and PVC pipes. We’ll explore whether it’s possible to connect them, discuss the differences between the two materials, highlight the importance of using the right glue, and provide tips for ensuring a safe and leak-free joint. Plus, we’ll weigh the pros and cons of using ABS versus PVC pipes so that you can make an informed decision about which type is right for your project.

Whether you’re an experienced DIYer or just starting out, this guide will equip you with everything you need to know about connecting ABS pipe to PVC – safely and correctly.

What is ABS Pipe?

Contents

- 1 What is ABS Pipe?

- 2 What is PVC Pipe?

- 3 Similarities and Differences between ABS and PVC

- 4 Transition Cement: The Needed Adhesive to Connect ABS and PVC Pipes

- 5 How to Connect ABS Pipe to PVC Using Transition Cement

- 6 Benefits of Connecting ABS and PVC Pipes

- 7 Disadvantages of Connecting ABS and PVC Pipes

- 8 Alternatives to Connecting ABS and PVC Pipes

- 9 Conclusion

ABS, short for Acrylonitrile Butadiene Styrene, is a thermoplastic pipe that has become a go-to choice for various plumbing applications. Its ability to withstand high temperatures and resist chemicals makes it an ideal choice for hot water supply lines and industrial settings where harsh chemicals are present.

Manufactured by extruding a thermoplastic material through a die, ABS pipe typically comes in black and has a smooth surface that resists corrosion. It’s available in sizes ranging from ½ inch to 6 inches in diameter, giving you plenty of choices when selecting the right size for your project.

One of the main benefits of ABS pipe is its ease of installation. With the ability to be easily cut with either a handsaw or power saw, it can be joined together using solvent cement. ABS pipe fittings come in various shapes and sizes, including elbows, tees, couplings, and adapters, making it easy to customize your plumbing system.

It’s important to note that while ABS pipe can be connected to PVC using the appropriate materials and techniques, it may not always be the best solution for every plumbing project. In some cases, it may be more appropriate to use pipes and fittings made from a single material rather than attempting to connect two different types of plastic together.

When using ABS pipe for your plumbing needs, make sure to follow the manufacturer’s instructions carefully when using transition cement to connect it with PVC pipes. This will ensure a strong and secure connection that will last for years to come.

What is PVC Pipe?

PVC pipe, or polyvinyl chloride pipe, is a type of plastic pipe that is made from a combination of vinyl resin and stabilizers. This unique blend of materials gives PVC pipe its exceptional strength and durability while making it resistant to corrosion and chemical damage. In addition, PVC pipe is available in various sizes and thicknesses, making it ideal for a wide range of applications such as water distribution, sewage systems, drainage, electrical conduit, and insulation.

One of the most significant advantages of PVC pipe is its affordability. Compared to other materials like copper and steel, PVC pipe is much cheaper and easier to install. Additionally, its lightweight nature makes it perfect for DIY projects as it can be effortlessly handled and transported.

However, like any other material, PVC pipe does have its drawbacks. While it is a recyclable material, certain additives and stabilizers used in its production can make the recycling process difficult. Furthermore, when exposed to high temperatures or fire, PVC pipe can release toxic chemicals.

Despite these drawbacks, PVC pipe remains a popular choice for many plumbing and construction projects due to its affordability, durability, and versatility. It’s a great option for those who want a budget-friendly solution without compromising on quality.

Similarities and Differences between ABS and PVC

If you are in need of plastic pipes for your plumbing or construction project, you may have encountered two commonly used types: ABS and PVC. While there are some similarities between these two materials, there are also notable differences that should be taken into account before making a purchase.

Let’s start with the similarities between ABS and PVC pipes. Both types of plastic are lightweight and easy to install, making them ideal for DIY projects. They are also resistant to corrosion, which is crucial for water supply systems. Additionally, both ABS and PVC pipes come in various sizes and shapes to meet your specific plumbing needs.

However, the composition of ABS and PVC pipes is one key difference. ABS pipes are made from acrylonitrile butadiene styrene, a thermoplastic polymer, while PVC pipes are made from polyvinyl chloride, another type of thermoplastic polymer. This means that ABS is generally more flexible than PVC, but also less heat-resistant.

Speaking of temperature resistance, this is another significant difference between ABS and PVC pipes. PVC can handle higher temperatures than ABS, up to 140°F compared to ABS’s 180°F limit. As a result, PVC is typically used for hot water supply lines, while ABS is preferred for drainage systems.

It is also important to note that connecting ABS and PVC pipes directly without a transition fitting is not recommended due to the different properties of these two materials. Transition fittings are specifically designed to join ABS and PVC pipes together safely and securely.

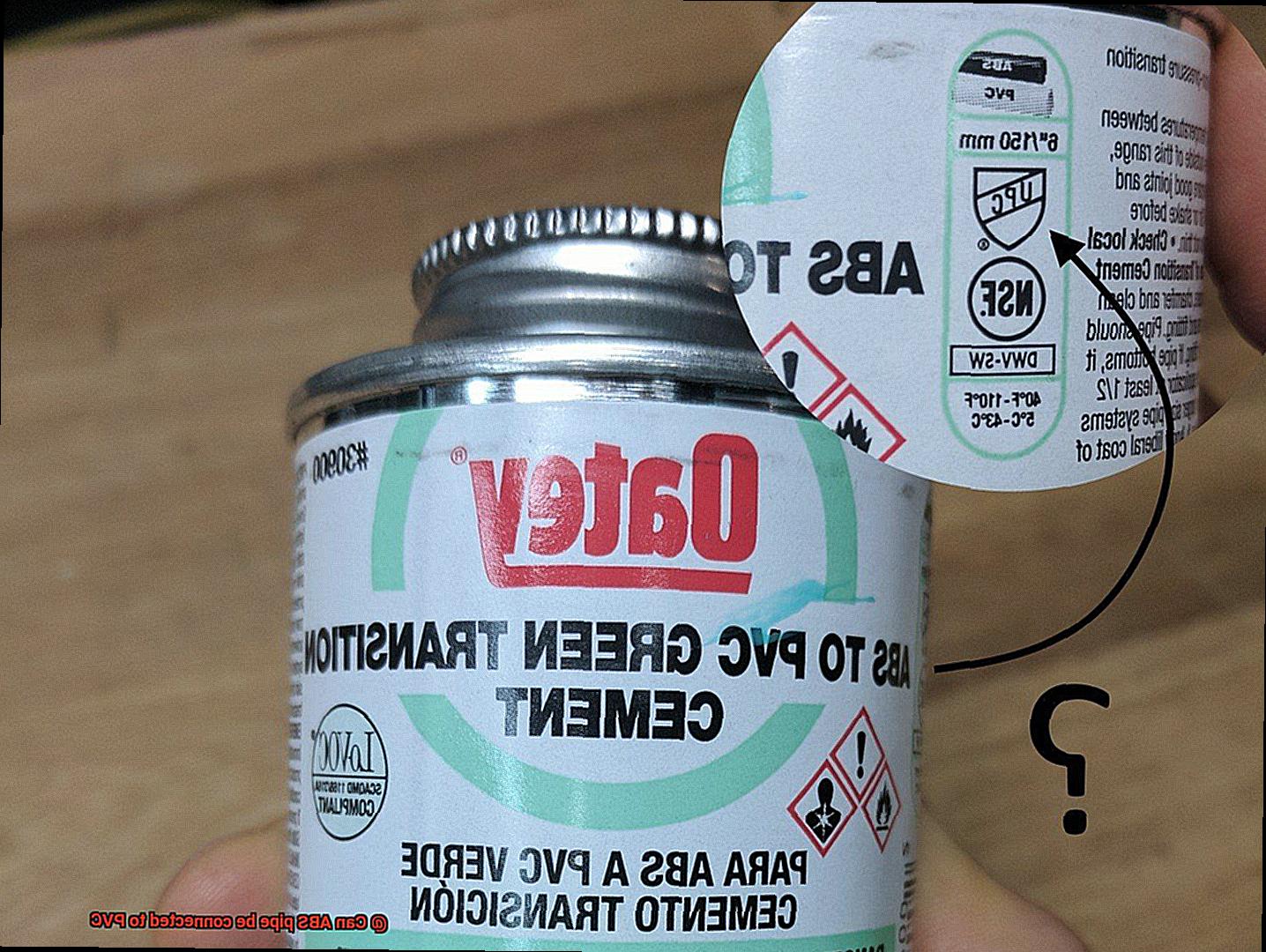

Transition Cement: The Needed Adhesive to Connect ABS and PVC Pipes

Connecting ABS and PVC pipes can be a tricky task, as traditional methods such as solvent welding are not effective. However, there is a solution – transition cement, a specific type of adhesive that is designed to connect these two types of pipes. But what exactly is it, and how does it work?

Transition cement works by softening the surface of the plastic, allowing it to fuse together when pressure is applied. This makes it an essential tool in connecting ABS and PVC pipes, which cannot be connected using regular adhesives. However, it’s important to use the correct type of transition cement for the specific materials being used, as not all adhesives are compatible with both ABS and PVC.

When using transition cement, following the manufacturer’s instructions carefully is crucial. This includes ensuring that both surfaces are clean and dry before applying the adhesive. The cement should be applied evenly to both surfaces and allowed to dry completely before connecting the pipes.

While transition cement can be an effective solution for connecting ABS and PVC pipes, it may not always be a permanent one. Over time, the adhesive can break down, potentially causing the connection to weaken or fail altogether. In some cases, it may be necessary to replace the entire section of piping rather than attempting to repair a connection made with transition cement.

To determine if transition cement is right for your project, consider factors such as the materials being used, the specific application, and your own level of expertise. If unsure about whether or not transition cement is the best option for your project, consult with a professional plumber.

How to Connect ABS Pipe to PVC Using Transition Cement

Connecting ABS pipe to PVC using transition cement can be a tricky process, but it is definitely achievable with the right tools and techniques. Here are five steps to help you connect ABS pipe to PVC using transition cement.

Step 1: Clean the Pipes

Before beginning the process of connecting ABS pipe to PVC using transition cement, make sure that both pipes are clean and free from any debris or contaminants. Clean the surfaces where you will be applying the cement with a rag or paper towel and some rubbing alcohol.

Step 2: Apply Transition Cement

Apply a generous amount of transition cement to the end of the ABS pipe. Be sure to apply the cement evenly and cover the entire surface area of the pipe. Follow the manufacturer’s instructions carefully, as the application process may vary depending on the brand of cement you are using.

Step 3: Insert ABS Pipe into PVC Fitting

Once the cement has been applied, insert the ABS pipe into the PVC fitting or pipe. Twist the pipe slightly to ensure that it is fully seated in the fitting or pipe. Hold the pipe in place for several seconds to allow the cement to set.

Step 4: Repeat for Additional Pipes

Repeat this process for any additional ABS pipes that need to be connected to PVC. Ensure that each connection is fully seated and held in place for several seconds before moving onto the next one.

Step 5: Allow Cement to Dry Completely

Once all of the connections have been made, allow the cement to dry completely before using the pipes. This will ensure that a strong and reliable bond is formed between the two types of plastic pipes.

It is important to note that while transition cement is designed to bond ABS and PVC together, it may not be suitable for every application. For example, if you are connecting pipes that will be carrying hot or pressurized fluids, you may need to use a different type of adhesive or connector. It is always a good idea to consult with a professional plumber or contractor before attempting any DIY plumbing projects.

Benefits of Connecting ABS and PVC Pipes

When it comes to plumbing, connecting different types of pipes can be a challenge. Two common types of plumbing pipes that are widely used in residential and commercial plumbing systems are ABS and PVC pipes. Although it is generally not recommended to connect ABS and PVC pipes directly, there are certain benefits to doing so that may surprise you.

One of the main benefits of connecting ABS and PVC pipes is the ability to use existing plumbing systems. This is particularly beneficial if you have an older plumbing system that uses ABS pipes, but you want to upgrade your fixtures or appliances that require PVC pipes. By simply connecting the two types of pipes using a special adapter or coupling, you can save both time and money compared to having to replace your entire plumbing system.

Another advantage of connecting ABS and PVC pipes is the increased flexibility in plumbing design. The ability to use both types of pipes allows plumbers to create more versatile plumbing systems that can accommodate different types of fixtures and appliances. This is particularly useful in commercial buildings where there may be a variety of plumbing needs.

In addition to the above benefits, connecting ABS and PVC pipes can also help reduce the risk of leaks and other plumbing problems. When properly connected using the appropriate materials, these pipes can create a tight seal that prevents water from leaking out. This not only helps prevent damage to your home or property, but it also reduces the need for costly repairs down the line.

Overall, although proper installation techniques must be followed when connecting ABS and PVC pipes, there are certainly benefits to doing so. To summarize, here are some key advantages:

- Ability to use existing plumbing systems

- Increased flexibility in plumbing design

- Reduced risk of leaks and other plumbing problems

Disadvantages of Connecting ABS and PVC Pipes

While combining these two materials may seem like an easy solution to your plumbing needs, there are several disadvantages that you need to consider before making any decisions.

The first drawback to connecting ABS and PVC pipes is their difference in expansion and contraction rates. These two materials expand and contract at different rates when exposed to changes in temperature. This means that the joint between the two pipes can weaken over time, leading to leaks or even complete failure. The consequences of such failures can be costly and time-consuming to repair.

Another disadvantage of connecting ABS and PVC pipes is the risk of chemical reactions between the two materials. ABS is more resistant to chemicals than PVC, and if certain chemicals are present in the system, they can cause damage to the PVC pipe. This can weaken the joint over time, leading to leaks or even failure. Such damages can compromise the integrity of your plumbing system and pose significant health hazards.

In addition, ABS and PVC pipes have different physical properties such as stiffness and impact resistance. These differences mean that the joint between them may not be as strong as a joint made with pipes of the same material. This weakness can be especially problematic if the pipes are carrying pressurized water or other fluids, which can cause serious leaks or bursts.

Finally, it’s essential to note that connecting ABS and PVC pipes may not be up to code in some areas. Local building codes may require that pipes of the same material be used for specific applications, and using different types of pipes may violate these codes. Failing to adhere to these codes could result in legal penalties and jeopardize your safety.

Alternatives to Connecting ABS and PVC Pipes

While traditional methods involve cement glue designed for each specific type of pipe, there are other options available that can be just as efficient.

One alternative is to use a mechanical coupling, which connects the two pipes together without the need for messy glue. These couplings consist of two pieces that fit over the ends of the ABS and PVC pipes and are secured in place with screws or clamps. They’re an excellent choice for DIY projects since they’re easy to install and remove.

Another option is to use transition fittings specifically designed to connect ABS and PVC pipes. These fittings have one end that fits over the ABS pipe and another end that fits over the PVC pipe, creating a secure connection between the two. They’re a reliable choice for professionals and DIY enthusiasts alike.

It’s crucial to note that while these alternatives can be effective, they may not be suitable for all plumbing applications. It’s always best to consult with a professional plumber or contractor before attempting any DIY plumbing projects, especially when it comes to connecting different types of pipes.

fT3Ic18xupw” >

Conclusion

In conclusion, the question of whether ABS pipe can be connected to PVC requires careful consideration and attention to detail. While these two types of plastic pipes share some similarities, they also have notable differences in composition and properties. Therefore, it’s crucial to use the appropriate glue or transition cement when joining them together.

ABS pipe is a thermoplastic polymer that boasts high-temperature resistance and chemical resistance, making it ideal for hot water supply lines and industrial applications. On the other hand, PVC pipe is affordable, durable, and versatile due to its combination of vinyl resin and stabilizers.

Transition cement works by softening the surface of the plastic and bonding them together under pressure. However, proper installation techniques must be followed to ensure a strong and reliable bond between ABS and PVC pipes.

While there are benefits to connecting ABS and PVC pipes – such as increased flexibility in plumbing design and reduced risk of leaks – there are also drawbacks to consider. These include differing expansion rates, potential chemical reactions between materials, weaker joints compared to same-material joints, and possible code violations.

If you’re planning a DIY plumbing project involving ABS or PVC pipes or need to upgrade your existing plumbing system without replacing it entirely, consulting with a professional plumber or contractor is essential. This will ensure that your project adheres to safety regulations while being efficient and up-to-code.

In summary, connecting ABS pipe to PVC is possible but should be done with caution.