Got a shoe that needs fixing or some materials that need bonding?

You’re gonna want an adhesive that can handle the job. That’s where Shoe Goo and Gorilla Glue come in.

These bad boys are known for their strength and durability, but which one is really the toughest? In this blog post, we’re gonna break it down for you.

We’ll compare Shoe Goo and Gorilla Glue, looking at what they bring to the table. So whether you’re a DIY pro or just need a reliable adhesive, we’ve got you covered.

Let’s find out which one is the real deal.

Characteristics of Shoe Goo

Contents

- 1 Characteristics of Shoe Goo

- 2 Characteristics of Gorilla Glue

- 3 Comparing the Strength of Shoe Goo and Gorilla Glue

- 4 Applications for Shoe Goo

- 5 Applications for Gorilla Glue

- 6 Factors that Affect Bond Strength

- 7 Surface Preparation and Curing Time

- 8 Pros and Cons of Shoe Goo vs Gorilla Glue

- 9 Conclusion

Fortunately, Shoe Goo offers the solution to extend the lifespan of your cherished footwear. This blog post will delve into the various characteristics of Shoe Goo that make it the ultimate adhesive for shoe repairs.

Flexibility and Durability:

Shoe Goo stands out for its impressive flexibility, setting it apart from other adhesives prone to cracking or breaking under pressure. With Shoe Goo, your shoe repairs can withstand bending, stretching, and twisting without compromising their bond.

This makes it perfect for repairing soles that experience constant movement and stress, ensuring your shoes stay intact even during intense activities.

Resistance to Water and Solvents:

Say goodbye to worries about your shoes falling apart after stepping in a puddle or getting caught in the rain. Shoe Goo exhibits remarkable resistance to water and most solvents, ensuring that your repairs remain strong even in wet conditions. Whether you’re traversing rain-soaked streets or accidentally spill a drink on your shoes, Shoe Goo has got you covered.

Versatility:

Living up to its name, Shoe Goo is incredibly versatile. It can adhere to a wide range of materials commonly found in shoes, including leather, rubber, fabric, and vinyl. Whether you need to repair running shoes, dress shoes, sneakers, or even heels, Shoe Goo is up to the task.

Seamless Repairs:

Nobody wants their shoe repairs to be glaringly obvious or unsightly. That’s why one of the most appealing characteristics of Shoe Goo is its ability to dry clear. Once your repairs are complete, there will be no visible marks or residue left behind. Your shoes will look as good as new without any evidence of the repair work.

Strong Bond:

When it comes to adhesive strength, Shoe Goo reigns supreme. It provides a powerful bond that can withstand heavy use, ensuring that your repairs hold up over time. However, it’s crucial to follow the manufacturer’s instructions for optimal results, as the strength of Shoe Goo may vary depending on the specific application and the materials being bonded.

Characteristics of Gorilla Glue

Look no further than Gorilla Glue. With its impressive characteristics, this adhesive is a go-to choice for both household repairs and professional projects.

One of the standout features of Gorilla Glue is its polyurethane-based formula. Made from a unique combination of chemicals, this adhesive forms an incredibly strong bond when cured. From wood to metal, glass to foam, Gorilla Glue can securely bond a wide range of materials.

Waterproof and weather-resistant, Gorilla Glue is built to last. Whether you’re repairing something indoors or tackling an outdoor project, this adhesive won’t let you down. No need to worry about your repairs coming undone when exposed to moisture or humidity. Gorilla Glue holds strong, rain or shine.

One characteristic that sets Gorilla Glue apart is its expansion as it cures. This unique quality allows the adhesive to fill in any gaps or voids in the material being bonded, ensuring a tight and secure connection. However, it’s important to apply the glue carefully to avoid excessive foaming.

Once fully cured, Gorilla Glue dries to a tan color that can be sanded, painted, and stained to match your desired finish. Whether you’re working on furniture or crafts, this adhesive can be easily customized to meet your needs.

When it comes to strength, Gorilla Glue surpasses expectations. It can withstand heavy loads and stress with ease, making it the ideal choice for both everyday repairs and professional projects. Say goodbye to weak adhesives that buckle under pressure.

While curing time varies depending on factors such as temperature and humidity, Gorilla Glue typically takes 24 hours to fully cure. However, keep in mind that longer curing times may be necessary for specific applications or under certain conditions. Patience is key when working with this powerful adhesive.

Comparing the Strength of Shoe Goo and Gorilla Glue

When it comes to shoe repairs, having the right adhesive is crucial. In the world of footwear fixes, two heavyweights often come to mind: Shoe Goo and Gorilla Glue. Both adhesives have their strengths, but how do they compare when it comes to strength?

Let’s start with Shoe Goo, a specialized adhesive designed specifically for shoe repairs. This stuff lives up to its reputation. Known for its flexibility and durability, Shoe Goo is a reliable choice for fixing worn-out soles, repairing damaged heels, and mending other shoe parts. It forms a strong bond on rubber, leather, fabric, and other shoe materials. When it comes to handling the stresses and movements associated with shoes, Shoe Goo is a solid option.

Now let’s turn our attention to Gorilla Glue, the superhero of adhesives. This versatile adhesive can bond almost any surface together with incredible strength. From wood to metal to ceramics and even foam, Gorilla Glue does it all. It expands as it cures, creating a tight hold that can withstand heavy loads and stress. While not specifically designed for shoe repairs like Shoe Goo, Gorilla Glue can still provide a strong and durable hold on shoe parts.

It’s important to note that the strength of both adhesives also depends on the application and the surface they are being used on. Shoe Goo may excel in bonding certain types of shoe materials like rubber or leather, while Gorilla Glue may perform better on other surfaces like wood or metal.

Ultimately, the choice between Shoe Goo and Gorilla Glue depends on your specific needs. If you’re primarily looking for a shoe repair adhesive, Shoe Goo’s specialized formulation makes it an excellent choice. However, if you require a versatile adhesive that can bond various materials, Gorilla Glue may be more suitable.

Remember, the strength of an adhesive is not solely determined by the brand but also by proper application and preparation of the surfaces being bonded. So, make sure to clean, dry, and align the surfaces before applying the adhesive for a stronger bond.

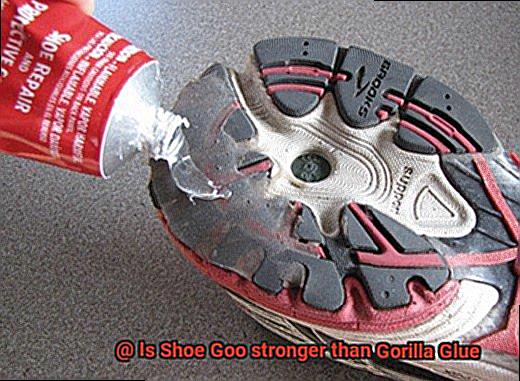

Applications for Shoe Goo

Picture this: you’re strutting down the street, feeling confident and stylish in your favorite pair of shoes, when disaster strikes. Suddenly, your shoes fall victim to a worn-out sole or a detached heel. But fear not, my fellow shoe enthusiasts, because Shoe Goo is here to save the day.

Shoe Goo is not your ordinary adhesive. It’s a superhero in a tube, specifically designed for repairing and protecting shoes. With its strong bonding properties and flexible nature, Shoe Goo is the ultimate weapon against shoe disasters.

Let’s dive into its primary mission: shoe repairs. Shoe Goo has the power to mend holes, seal cracks, and reinforce weak areas on your beloved footwear. Whether it’s a worn-out sole or a loose insole, Shoe Goo can securely bond these components back in place, ensuring a durable repair that can withstand daily wear and tear.

Shoe Goo isn’t limited to just shoe repairs. It has an entire arsenal of other applications that make it an essential tool in any DIY enthusiast’s workshop.

For starters, Shoe Goo can be used as a protective coating on shoe soles. By applying a layer of Shoe Goo, you can prevent premature wear and tear, ensuring that your shoes last even longer. Its thick and flexible nature creates a durable barrier that guards against abrasion and impact.

But why stop at shoe repairs? Shoe Goo is also perfect for creating custom shoe modifications. Need extra traction or grip on the soles of your shoes? Just apply a textured layer of Shoe Goo and voila. You’ll be ready to conquer any terrain, whether it’s skateboarding at the park or hiking up a mountain.

And guess what? Shoe Goo isn’t confined to just shoes. It can also repair other types of footwear, such as boots, sandals, and athletic shoes. Its strong bonding properties make it effective for fixing various materials, including leather, rubber, canvas, and fabric.

But wait, there’s even more. Shoe Goo can be your trusted sidekick in everyday household repairs. It can bond materials like rubber, vinyl, plastic, and fabric, making it suitable for fixing items such as inflatable toys, raincoats, backpacks, and even upholstery.

Applications for Gorilla Glue

Prepare to meet the superhero of adhesives – Gorilla Glue. Renowned for its unmatched strength and durability, this adhesive is a must-have for a wide range of applications.

Whether you’re a woodworking enthusiast, a DIY aficionado, or simply someone who loves to get creative, Gorilla Glue has got you covered. Join me as we explore the various ways this versatile adhesive can be used.

Woodworking Wonder:

Calling all carpenters and woodworkers. Gorilla Glue will be your new best friend in the workshop. Seamlessly bonding wood pieces together? Check. Filling gaps and repairing broken furniture? Check. With Gorilla Glue, weak joints and loose pieces will be a thing of the past. Your projects will stand the test of time with this adhesive’s unbeatable strength.

Construction Champ:

The construction industry swears by Gorilla Glue’s exceptional properties. When it comes to securely bonding heavy-duty materials like stone, metal, and concrete, this adhesive takes the crown.

Building a patio or securing fixtures in place? Gorilla Glue is your go-to choice for a rock-solid finish that withstands the test of time.

Automotive Ace:

Car troubles? Fear not. Gorilla Glue comes to the rescue in the automotive world too. Fixing cracks in car parts? Consider it done. Attaching trim pieces and sealing leaks? Gorilla Glue is your reliable solution.

Bid farewell to costly repairs and say hello to an adhesive that keeps your vehicle running smoothly.

Arts and Crafts Extraordinaire:

Calling all artists and crafters. Gorilla Glue is your secret weapon for creating masterpieces. Its ability to bond various materials like fabric, plastic, and foam is unparalleled.

Designing jewelry, crafting decorative items, or bringing imaginative ideas to life? Gorilla Glue will hold everything together beautifully, giving your creations a lasting perfection.

Household Hero:

Have you ever accidentally broken a favorite dish or mug? Gorilla Glue is here to save the day. Its adhesive power extends to ceramic and glass, allowing you to repair those sentimental items with ease. Even fixing aquariums and other fragile objects becomes a breeze with Gorilla Glue’s strength and reliability.

DIY Delight:

Get ready to unleash your creativity with Gorilla Glue on your side in DIY projects. Building small-scale models or designing custom modifications? This adhesive will be your trusty companion throughout the entire process. Let your imagination run wild – Gorilla Glue can handle it all.

Factors that Affect Bond Strength

Look no further than Shoe Goo and Gorilla Glue. These adhesives are renowned for their exceptional bond strength, ensuring your repairs and projects last a lifetime. But what secrets lie behind their superpower? Let’s dive in and explore the factors that contribute to their incredible bonding capabilities.

Surface Preparation:

Just like superheroes need a clean slate to work their magic, Shoe Goo and Gorilla Glue require clean and dry surfaces for optimal bonding. Dust, dirt, oil, or moisture can hinder the adhesives’ ability to create a strong bond. Thoroughly cleaning the surfaces beforehand unleashes the full potential of these adhesive superheroes.

Adhesive Compatibility:

Every superhero has its kryptonite, and the same goes for adhesives. Shoe Goo specializes in shoe repairs, excelling on various materials like rubber, leather, and fabric. Meanwhile, Gorilla Glue is a versatile adhesive that bonds different materials such as wood, metal, ceramic, and more. Understanding the compatibility of each adhesive with your materials is crucial for achieving maximum bond strength.

Application Method:

Even superheroes require precision when applying their powers, and the same goes for adhesives. Following the specific application instructions provided with Shoe Goo and Gorilla Glue is essential. Applying too much or too little adhesive weakens the bond. Ensuring even coverage across the entire bonding surface is vital for consistent strength.

Curing Time:

Patience is a virtue that even superheroes possess. Curing time refers to the period it takes for the adhesive to dry completely and reach its maximum strength. Rushing this process can result in weaker bonds, so exercise some patience and let the adhesive work its magic.

Environmental Conditions:

Just like superheroes operate differently in various environments, adhesives are also affected by their surroundings. Temperature, humidity, and exposure to moisture can impact performance. To ensure optimal bond strength, follow the manufacturer’s recommendations regarding temperature and humidity ranges during application and curing.

Surface Preparation and Curing Time

When it comes to glue, surface preparation and adhering to the recommended curing time are the secret ingredients that make adhesive superheroes like Shoe Goo and Gorilla Glue truly powerful. In this blog post, we’ll dive into the importance of these two crucial steps and provide an in-depth analysis of how they can make or break your bonding projects.

Surface Preparation:

- Cleaning: Before applying any glue, it’s essential to clean the surfaces to be bonded. Use a mild detergent and a clean cloth to remove dirt, dust, and oils that could hinder adhesion.

- Roughening: To enhance bonding strength, roughen the surfaces slightly using sandpaper or a file. This creates more surface area for the glue to grip onto.

Curing Time:

- Shoe Goo: This adhesive typically requires 24 hours to cure completely. Factors like temperature and humidity can affect curing time. During this period, avoid stressing the bond or exposing it to water or extreme temperatures.

- Gorilla Glue: While Gorilla Glue sets within 1-2 hours, it needs a full 24 hours to cure and reach maximum strength. Take similar precautions as with Shoe Goo during this period.

Importance of Surface Preparation:

- Enhances adhesion: Proper cleaning and roughening create an optimal bonding surface, allowing the glue to grip tightly.

- Maximizes bond strength: A strong bond relies on a clean surface free from contaminants that could weaken adhesion.

- Ensures durability: By preparing the surface correctly, you set the foundation for a long-lasting bond that withstands stress and environmental factors.

Adhering to Recommended Curing Time:

- Strengthens bond: Rushing through curing compromises bond strength and durability.

- Prevents premature failure: Allowing the adhesive to fully cure ensures maximum strength, preventing premature failure in the bonded area.

Pros and Cons of Shoe Goo vs Gorilla Glue

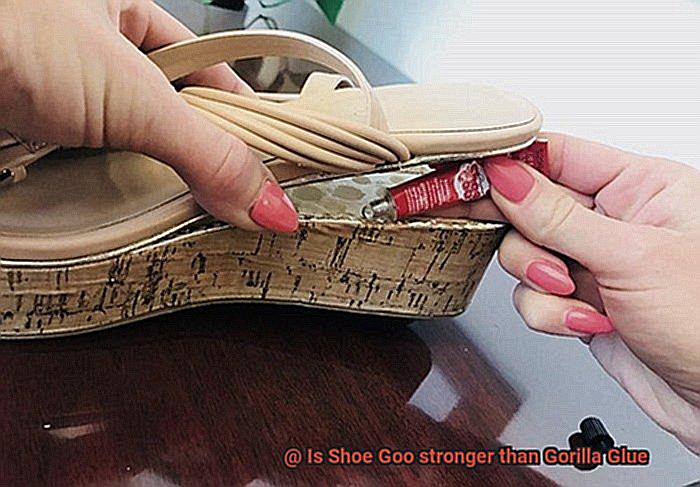

Shoe repairs can be a hassle, but with the right adhesive, you can save your favorite pair of shoes from retirement. Two popular choices for shoe repairs are Shoe Goo and Gorilla Glue. Let’s dive into the pros and cons of these glues to help you make an informed decision.

Shoe Goo is specifically designed for shoe repairs, making it a reliable choice for fixing soles, heels, and other shoe parts. It boasts exceptional strength and durability, able to withstand heavy usage and wear.

With its flexible nature, Shoe Goo can move with the shoe material without cracking or losing adhesion, which is essential for shoes that undergo frequent bending or twisting.

Additionally, its water-resistant properties ensure that your repaired shoes stay dry even in wet conditions. Application is a breeze with its convenient tube and easy-to-use applicator tip.

However, Shoe Goo does have some drawbacks. Its long curing time of up to 24 hours or more can be inconvenient if you need a quick repair or don’t have any spare shoes to wear in the meantime. Furthermore, Shoe Goo’s effectiveness may be limited when used on materials other than shoes.

On the other hand, Gorilla Glue offers versatility beyond shoe repairs. It can bond a wide range of materials like wood, metal, plastic, and fabric. Its strong bond creates long-lasting adhesion that fills gaps and creates a tight seal. Gorilla Glue also has a relatively fast curing time, drying within 1-2 hours.

When it comes to cost, both glues are reasonably priced for their performance and durability. However, Gorilla Glue may offer more value due to its versatility and ability to tackle various repair projects.

R_r53OCHYKU” >

Conclusion

In the battle of Shoe Goo versus Gorilla Glue, it’s clear that Shoe Goo reigns supreme. This powerful adhesive is a force to be reckoned with, surpassing the strength and durability of Gorilla Glue.

When it comes to repairing shoes, Shoe Goo is the ultimate savior. Its unmatched bond can withstand the toughest conditions, ensuring your shoes stay intact even in the face of extreme wear and tear.

But don’t just take my word for it. The proof lies in its incredible performance. With Shoe Goo, you can say goodbye to loose soles and frayed edges. It forms a resilient barrier that not only fixes but also reinforces your beloved footwear.

On the other hand, Gorilla Glue falls short in comparison. While it may have its uses in various applications, when it comes to shoe repair, it simply doesn’t measure up. Its adhesive properties pale in comparison to the mighty Shoe Goo.

So why settle for anything less than the best? Choose Shoe Goo for all your shoe repair needs and experience unparalleled strength and longevity. Don’t let your favorite pair of shoes suffer – trust in Shoe Goo’s unrivaled power to keep them going strong for years to come.

In conclusion, when pitted against each other, there’s no denying that Shoe Goo emerges as the victor. Its exceptional strength and durability make it the go-to choice for shoe repairs, leaving Gorilla Glue trailing behind.