When it comes to adhesives, the age-old question is, “Is epoxy stronger than glue?” As a DIY enthusiast or professional builder, you know that choosing the right adhesive can make or break your project. Adhesives are like the glue that holds everything together, from constructions to furniture repairs. But with so many options on the market, it’s hard to know which one reigns supreme.

Enter epoxy, the high-performance adhesive that boasts unrivaled strength and versatility. Used primarily in industries such as automotive and aerospace for decades, epoxy has recently become popular in construction, flooring, and electronics due to its incredible bonding strength. However, with great power comes a higher cost compared to regular glue, leading some to question its effectiveness.

So what’s the difference between epoxy and glue? In this blog post, we’ll explore their fundamental properties and applications to answer the ultimate question: Is epoxy stronger than glue? By the end of this post, you’ll have a clear understanding of why epoxy is worth every penny and how it outperforms regular glue in almost every way imaginable. So sit back and get ready to become an expert on adhesives.

What is Epoxy?

Contents

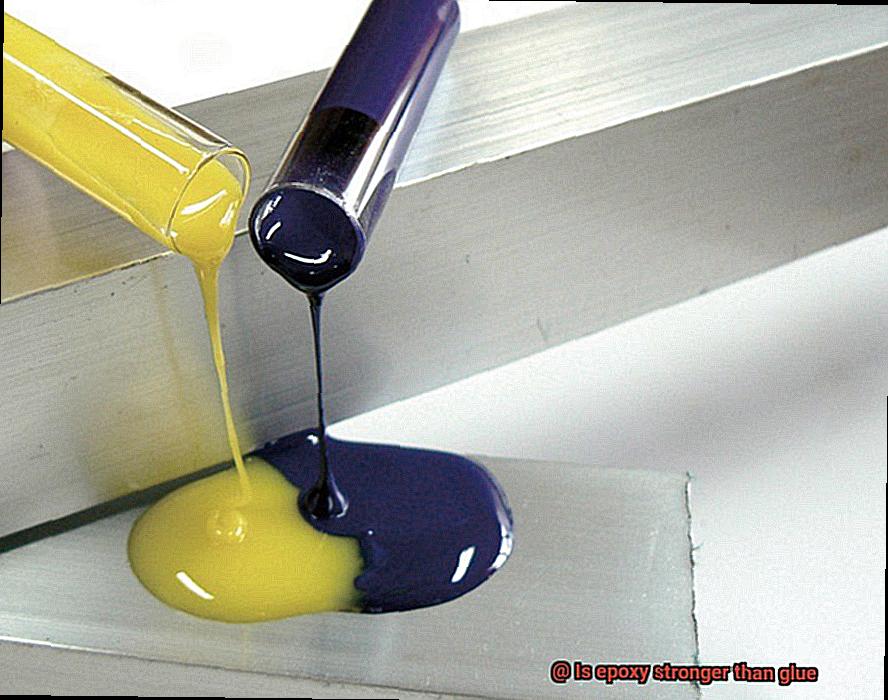

It is a two-part adhesive made of resin and hardener which, when combined, create a powerful and permanent bond. The magic of epoxy lies in its exceptional ability to penetrate surface pores, creating an unbreakable bond that is resistant to water, chemicals, and extreme temperatures.

Epoxy’s versatility and durability make it a popular choice for a wide range of applications. Here are just a few examples:

- Concrete Repair – Epoxy is an excellent solution for fixing cracks in concrete floors, walls or filling gaps because of its exceptional strength and durability.

- Woodworking – Epoxy is perfect for woodworking projects such as filling gaps or cracks in wood or as a finish for woodwork.

- Automotive Repair – Epoxy is commonly used in automotive repair for fixing dents and cracks in car bodies.

- Industrial Manufacturing – Epoxy is widely used in industrial manufacturing for bonding materials such as metal, plastic, and composite materials.

However, not all epoxies are created equal. Different formulations have varying properties such as cure time, viscosity, and maximum strength. It’s crucial to select the right epoxy for your specific application to achieve optimal results. While epoxy is an excellent choice for many applications, other types of adhesives may be better suited for certain projects such as polyurethane glue or cyanoacrylate (super glue).

What is Glue?

Glue is a versatile adhesive that can be made from natural substances such as animal hides and plant resins, or synthetic materials like polymers and cyanoacrylates.

It’s commonly used in a wide range of applications, from woodworking to electronics. Glues can be formulated to dry quickly or take longer to set, and some are water-resistant while others are not.

Certain types of glue are specifically designed for use with particular materials such as fabric or plastic. Did you know that epoxy is often considered the superhero of adhesives?

Epoxy has the ability to penetrate surface pores and create an unbreakable bond that can endure extreme temperatures and harsh chemicals.

Comparing the Strength of Epoxy and Glue

The battle between epoxy and glue has arrived. But which one should you choose for your project? Let me, an expert in comparing the strength of epoxy and glue, break it down for you.

First, let’s delve into the different types of glue. Wood glue is a versatile adhesive that’s perfect for woodworking projects where a strong bond is necessary but flexibility is also important. Superglue, on the other hand, is perfect for small repairs or quick-drying projects. If you’re working with non-porous materials, cyanoacrylate glue is your best bet.

Now, let’s talk about the superstar – epoxy. Epoxy is considered one of the strongest adhesives out there due to its ability to form a chemical bond with surfaces, creating an unbreakable hold. Additionally, it’s resistant to water and heat, making it ideal for heavy-duty applications.

But wait, not all epoxies are created equal. Depending on the specific formulation and intended use, some epoxies may be stronger or more durable than others. Be sure to carefully follow the manufacturer’s instructions to ensure optimal performance.

So, how do you choose between epoxy and glue? Consider the specific application. If you need a strong bond with some flexibility, go for wood glue. For quick repairs or small projects, superglue or cyanoacrylate glue may be best. And if you need superhero strength for heavy-duty applications, epoxy is your go-to.

Advantages of Using Epoxy

Its incredible strength, versatility, and resistance to moisture make it a superhero in the realm of adhesives. Here are some of the top advantages of using epoxy:

First and foremost, epoxy’s strength is unmatched. When it comes to heavy-duty applications, there’s no better choice than this adhesive. It can handle high levels of stress and strain without breaking down or losing its adhesive properties.

In addition to its strength, epoxy also has a longer curing time than traditional glue, which allows for a longer working time. This means you have more time to position your materials correctly before the adhesive sets, ensuring a perfect fit.

Once it sets, epoxy becomes impervious to moisture, making it ideal for use in wet environments or applications that require exposure to water. Its resistance to water and other liquids also means that it won’t break down or lose its adhesive properties over time.

Epoxy is incredibly versatile and can be used on a wide range of materials, including metal, wood, concrete, and plastic. This makes it useful for a variety of applications.

But perhaps one of the most significant advantages of using epoxy is its ability to fill gaps and cracks in materials. This makes it ideal for repairing damaged surfaces or creating a seamless bond between two uneven surfaces.

And last but not least, durability is a major advantage of using epoxy. It can withstand high levels of stress and strain without breaking down or losing its adhesive properties over time. This makes it an excellent choice for applications that require a strong and long-lasting bond.

Disadvantages of Using Epoxy

While it’s true that epoxy is a superhero of adhesives, with unmatched strength and durability, its disadvantages should be carefully considered before use.

Firstly, let’s talk about the toxicity of epoxy. It contains harmful chemicals that can cause skin irritation, respiratory problems, and even cancer. Safety should always be a top priority when handling epoxy. Protective gear is a must to avoid any negative health effects.

Secondly, unlike glue that dries quickly, epoxy takes much longer to cure. This can be problematic when working on time-sensitive projects or in low-temperature environments. You’ll need to factor in this curing time and plan accordingly.

Thirdly, working with epoxy can be challenging. Precise measurements and mixing ratios are required, and any errors can result in a weak bond or an incomplete cure. Once the epoxy has cured, it cannot be easily undone or removed without damaging the surface it was applied to.

Lastly, let’s talk about cost. Epoxy can be expensive compared to other types of adhesives. While it may be worth the investment for certain projects that require a strong bond and durability, it may not be practical for everyday use.

Advantages of Using Glue

Glue is a versatile adhesive that has been around for centuries and is a popular choice among consumers due to its numerous advantages. As an expert in this field, I can attest to the fact that using glue is a reliable way to bond materials together. Let’s dive into these benefits.

First and foremost, one of the most significant advantages of using glue is its ease of use. Unlike other bonding methods like welding that require specialized knowledge and equipment, most types of glue come in easy-to-use forms like liquid, paste, or spray. This feature makes it adaptable to different surfaces and materials, making it ideal for a range of applications. Additionally, most glues dry quickly, making the bonding process fast and efficient.

Another advantage of using glue is its strength. Different types of glues offer varying degrees of bonding strength, but generally, they provide a strong and durable hold. Polyurethane and cyanoacrylate are two types of glue that are known for their incredible bonding strength. However, it’s important to note that the strength of the bond may vary depending on the type of material being bonded, the environmental conditions, and the application method used.

Glue is also a versatile adhesive that can be used for various applications. It can bond materials such as wood, plastic, metal, and paper. There are also specialized glues available for specific applications such as fabric glue for textiles and ceramic glue for pottery. This versatility makes it an ideal adhesive choice for a range of projects.

Moreover, using glue is a cost-effective solution compared to other bonding methods like welding or mechanical fastening. Glue is readily available in most hardware or craft stores at an affordable price, making it accessible to individuals with varying budgets. Additionally, since glue doesn’t require any specialized equipment or tools, it eliminates the need for expensive machinery that other bonding methods might require.

Lastly, using glue is a cleaner alternative to other bonding methods. Welding produces fumes and debris while mechanical fastening requires drilling holes or creating joints that may weaken the material over time. Glue doesn’t produce any harmful by-products and doesn’t require any additional tools or equipment. This feature makes it a more environmentally friendly option for those looking to reduce their carbon footprint.

Disadvantages of Using Glue

In this article, we will explore the disadvantages of using glue and why it may not always be the best option for your project.

Firstly, let’s consider limited strength. Although glue can be strong, it is not as durable as other adhesives such as epoxy. This means that it may not be suitable for heavy-duty projects or for materials that need to withstand a lot of stress. If you’re looking for a long-lasting bond, you might want to consider using a different type of adhesive.

Another drawback of using glue is its drying time. Depending on the type of glue you use, it may take some time for it to dry. This can be frustrating if you need to complete your project quickly. Therefore, if you’re working on a tight deadline, you might want to opt for a quicker drying adhesive.

Now let’s focus on messy application. Applying glue can be messy and difficult to control, especially when working with small pieces or intricate designs. The excess glue can end up sticking to your hands or on the material itself, which can be hard to clean up. This can mar the appearance of your project and make it look unprofessional.

Moreover, many glues have a limited shelf life which means that they may not be effective if they are too old. This means that if you don’t use the glue quickly enough, it may not work properly when you need it. Thus, it is essential to check the expiration date before using any adhesive.

Lastly, removing glue can be a daunting task. If you make a mistake or need to remove the glue for any reason, it can be very difficult to do so without damaging the material. This can be especially problematic if you’re working with delicate materials that can easily tear or break.

Tips for Choosing the Right Adhesive

Choosing the right adhesive for your project is essential to ensure a strong and reliable bond. Here are five key factors to consider when selecting an adhesive:

Compatibility with Materials

One of the most crucial factors to consider is the compatibility of the adhesive with the materials you will be bonding. Different adhesives work better on certain materials than others, so it’s important to choose an adhesive that can bond both surfaces effectively.

Strength

Consider the strength of the bond required for your project. If you’re looking for a temporary fix, a weaker adhesive like white glue or hot glue may be sufficient. However, for a permanent and strong bond, epoxy or polyurethane adhesives are a better choice.

Viscosity

The viscosity of the adhesive is another important factor to consider. A thin adhesive may be better suited for delicate pieces, while thicker adhesives may be needed for larger surfaces.

Drying and Curing Time

Some adhesives dry quickly but take longer to fully cure, while others may take longer to dry but cure more quickly. This is an important consideration if you need your project to be ready to use quickly or if you need a stronger bond that will withstand heavy use over time.

Environmental Factors

Temperature and humidity can affect how well an adhesive bonds, so it’s important to choose an adhesive that can withstand the environmental conditions it will be exposed to.

djtKXkTqPUI” >

Conclusion

In summary, the verdict is in: epoxy reigns supreme as the stronger adhesive when compared to glue. Its unique ability to seep into pores and form an unbreakable bond that can withstand harsh conditions such as water, chemicals, and extreme temperatures make it the go-to choice for heavy-duty applications in industries like aerospace and automotive.

It’s important to note that not all epoxies are created equal, so it’s crucial to choose the right one for your specific project needs. On the other hand, while glue has been a reliable adhesive for centuries and offers benefits such as affordability and ease of use, its strength may not be sufficient for high-stress projects or materials.

When selecting an adhesive, several factors must be taken into account. These include compatibility with materials, required strength, viscosity of the adhesive, drying and curing time needed, and environmental factors.