Are you itching to know just how long the trusty Titebond Hide Glue can hold its ground? Well, you’ve stumbled upon the perfect place to quench your thirst for adhesive knowledge. So grab a cuppa, sit back, and let me be your adhesive sommelier as we uncover the secrets behind this glue’s remarkable durability.

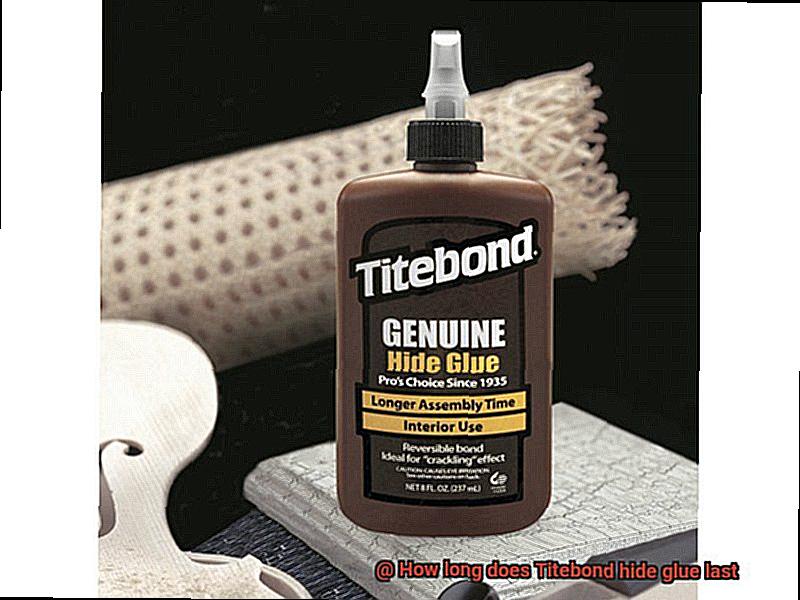

In a world where instant adhesives and modern marvels hog the spotlight, Titebond Hide Glue has quietly maintained its position as a reliable and timeless companion for woodworking enthusiasts and professionals alike. Composed of animal collagen and water, this adhesive has been keeping projects intact since its invention in the early 20th century.

But here’s the million-dollar question: how long can you expect this super glue to last? Buckle up, my friends, because we’re about to embark on a fascinating journey exploring the longevity and staying power of Titebond Hide Glue. From its composition and application to its ability to withstand the test of time, we’ll address all those burning questions that have been gnawing at your brain.

Whether you’re a seasoned woodworker seeking reassurance for your cherished creations or a curious DIYer eager to delve into the world of traditional adhesives, our exploration of Titebond Hide Glue’s lifespan will leave you armed with captivating insights and a newfound appreciation for this remarkable bonding agent.

So stick around (pun absolutely intended), as we dive headfirst into the realm of Titebond Hide Glue and unravel the secrets behind its long-lasting embrace. Your woodworking projects will thank you.

What is Titebond Hide Glue?

Contents

- 1 What is Titebond Hide Glue?

- 2 Factors Affecting the Longevity of Titebond Hide Glue

- 3 Proper Storage of Titebond Hide Glue

- 4 The Durability of Titebond Hide Glue

- 5 Application of Titebond Hide Glue

- 6 Curing Time for Titebond Hide Glue

- 7 Long-Term Performance of Titebond Hide Glue

- 8 Testing the Strength of Joints Bonded with Titebond Hide Glue

- 9 Conclusion

Derived from animal collagen, this traditional glue offers exceptional bonding properties and reversibility, making it ideal for various projects.

One of the unique characteristics of Titebond Hide Glue is its reversible nature. Unlike many other adhesives, hide glue can be easily softened and reactivated with heat and moisture. This means that if a joint needs to be disassembled or repaired, the glue can be loosened with hot water or steam, allowing for easy separation of the pieces without causing damage.

Titebond Hide Glue comes in different forms, including liquid, granular, and ready-to-use variants. Liquid hide glue is the most common form and is typically sold in bottles or containers. Granular hide glue requires mixing with water before use, while ready-to-use hide glue comes pre-mixed and does not require any additional preparation.

When it comes to the longevity of Titebond Hide Glue, proper storage is crucial. The key to prolonging its shelf life lies in ensuring that the glue remains tightly sealed and stored in a cool and dry environment, away from direct sunlight and extreme temperatures. Unopened bottles can last for several years under these conditions.

Once opened, it is recommended to use the glue within a year for optimal performance. Over time, exposure to air can cause the adhesive properties to degrade, resulting in weaker bond strength. Therefore, it’s important to keep the glue in airtight containers or bottles to minimize air exposure.

In terms of durability in woodworking projects, Titebond Hide Glue can maintain its bond strength for several decades when used correctly in well-executed projects. However, factors such as climate, humidity, and the type of wood used can influence its longevity. It’s essential to periodically inspect bonded joints for any signs of deterioration or weakness.

To maximize the shelf life of Titebond Hide Glue, it is recommended to follow best practices, such as using clean tools to prevent contamination and avoiding cross-contamination with foreign substances. Additionally, testing the glue on sample pieces or scrap materials before using it on important projects can help ensure desired results.

Factors Affecting the Longevity of Titebond Hide Glue

Titebond Hide Glue has been a favorite among craftsmen due to its exceptional bonding properties and ease of use. However, to ensure maximum longevity and long-lasting results, it is crucial to consider various factors that can affect its performance. In this article, we will delve into key factors that impact the longevity of Titebond Hide Glue, providing tips on how to overcome potential challenges.

Temperature and Humidity:

Extreme temperature fluctuations can cause Titebond Hide Glue to degrade or dry out faster. Similarly, high humidity levels can lead to mold or mildew growth, compromising the glue’s adhesive properties. To combat these issues, store the glue in a cool and dry place, shielded from direct sunlight and extreme temperatures. Additionally, consider using a dehumidifier or air conditioning in high humidity environments to maintain optimal conditions.

Application Technique:

Proper application techniques play a vital role in achieving long-lasting bonds with Titebond Hide Glue. Use a clean brush or roller to apply an even coat of glue onto the wood surface. Follow the manufacturer’s instructions for application and allow sufficient drying time for proper curing. By taking these extra steps, you ensure better adhesion and maximize longevity.

Wood Type:

Different wood types contain varying levels of natural oils or resins that can hinder adhesive bonding. Oily or resinous woods like teak or pine require preparation before applying Titebond Hide Glue. This preparation ensures better penetration and bond strength, ultimately enhancing longevity.

Exposure to Moisture:

Titebond Hide Glue is not waterproof; prolonged exposure to moisture weakens its bond over time. If constant water exposure or high humidity conditions are anticipated, consider using an adhesive with better water resistance. However, applying a protective finish over the glued joint can prolong its longevity when occasional exposure to moisture is expected.

Storage Conditions:

Proper storage is essential to maintain the longevity of Titebond Hide Glue. Store it in a cool, dry place, and tightly seal the container after each use to prevent drying out. By following these storage practices, you ensure that your glue maintains its adhesive properties for an extended period.

Proper Storage of Titebond Hide Glue

In the world of woodworking, the adhesive you choose can make or break your project. Titebond Hide Glue is renowned for its strong bonds and easy reversibility, but did you know that proper storage is essential for maintaining its effectiveness and prolonging its shelf life? In this article, we will explore the secrets of storing Titebond Hide Glue to ensure it remains in prime condition for all your woodworking endeavors.

Find the perfect spot:

Titebond Hide Glue is like a delicate flower; it thrives in a cool and dry environment, away from direct sunlight and extreme temperatures. Store it in a climate-controlled space, such as a workshop or storage cabinet, to prevent temperature fluctuations that can degrade its bonding properties.

Seal it tight:

Moisture is the enemy of hide glue, leading to clumping and reduced strength. Keep the glue container tightly sealed when not in use to prevent moisture absorption. If you notice thickening or exposure to moisture, fear not. A water bath can bring it back to life by restoring its original consistency.

Handle with care:

Hide glue is flammable, so keep it away from potential sources of ignition. While transferring it to an airtight container might seem like a good idea if the original packaging becomes compromised, remember that the original container is designed to preserve its quality.

Timing is everything:

Always check the expiration date of your Titebond Hide Glue. While it typically has a shelf life of one to two years, this can vary depending on storage conditions and other factors. If the glue has exceeded its expiration date or shows signs of degradation, discard it and invest in a fresh supply.

The Durability of Titebond Hide Glue

What sets this adhesive apart is its unique composition, derived from animal hide, specifically collagen. This natural ingredient imbues Titebond Hide Glue with its remarkable adhesive properties, capable of creating bonds that can withstand the test of time.

The secret to Titebond Hide Glue’s durability lies in its interaction with various materials. Particularly effective on porous surfaces such as wood, paper, and fabric, this glue forms a strong bond when applied correctly and allowed to dry. Unlike some other glues that become brittle or lose their adhesive properties over time, Titebond Hide Glue remains flexible and resilient. It adapts to the natural movements and changes in the material it adheres to without cracking or breaking.

Woodworking enthusiasts will find Titebond Hide Glue to be a reliable companion for their projects. Wood has a tendency to expand and contract with fluctuations in humidity and temperature, but fear not. This adhesive rises to the challenge. Its durability and flexibility make it the perfect choice for woodworking endeavors, ensuring that the bond remains secure even as the wood naturally shifts.

Another noteworthy feature of Titebond Hide Glue is its reversibility. In situations where modifications or repairs are needed down the line, this adhesive shines. Applying heat and moisture will loosen the bond, allowing for alterations without damaging the original material. It’s like having a glue that’s both strong and forgiving.

Application of Titebond Hide Glue

If you’re searching for a glue that can endure stress, provide an unyielding bond, and be effortlessly disassembled or repaired, you’ve come to the right place.

Before we delve into the application process, let’s quickly review what makes Titebond Hide Glue so exceptional. Derived from animal hides, this adhesive is composed of collagen, which grants it unparalleled bonding strength and durability. It’s ideal for woodworking projects that may necessitate future adjustments or repairs.

Now, let’s get down to business. The application process for Titebond Hide Glue is refreshingly straightforward. Here’s a step-by-step guide to assist you:

- Prepare the glue: Titebond Hide Glue is available in powdered form, so you’ll need to mix it with water. The recommended ratio is one part glue to two parts water. Allow the mixture to sit for at least 45 minutes to fully dissolve and activate.

- Clean the surfaces: Ensure that the surfaces you’re bonding are immaculate and devoid of any dirt or contaminants that could disrupt the bond.

- Apply the glue: With a brush or roller, apply a thin layer of glue to both surfaces being bonded. Exercise caution not to over-apply the glue as it can result in excessive squeeze-out.

- Let it dry: The drying time for Titebond Hide Glue varies depending on factors such as temperature and humidity, but typically dries within 24 hours. Patience is paramount.

- Clamp it together: Once the glue is applied, firmly clamp the pieces together to guarantee a robust bond. Appropriate clamping pressure is vital for a successful outcome.

- Clean up excess glue: Before the glue fully sets, any excess can be cleaned up with warm water. Removing any squeeze-out ensures a cleaner finish.

That’s it. With these simple steps, you’ll harness the power of Titebond Hide Glue and forge enduring bonds in your woodworking projects.

Remember, Titebond Hide Glue can be stored for an extended period if kept in a cool, dry place and properly sealed. However, for optimal performance, it’s advisable to use it within two years of purchase.

Curing Time for Titebond Hide Glue

When it comes to Titebond Hide Glue, patience is key. While the initial setting time is a mere 10-15 minutes, don’t be fooled – that’s not the full curing time. Oh no, my friend, you’ll have to wait a bit longer for that. The complete curing process can take anywhere from 24 hours to several days.

Why such a wide range, you ask? Well, it all depends on a few factors. Firstly, temperature plays a big role. If you’re working in warmer conditions, the glue will dry faster. On the other hand, lower temperatures can slow down the curing process. Humidity also has its say – higher humidity levels can extend the drying time, while lower levels speed it up.

To ensure a bond that will stand the test of time, it’s crucial to give Titebond Hide Glue enough time to fully cure before subjecting it to stress or load-bearing activities. Don’t rush it. You don’t want to risk weaker bond strength or potential failure of your adhesive joint.

Here’s a pro tip: Use clamps or other forms of pressure during the curing process. This helps squeeze out any excess glue, reduces air pockets, and enhances the adhesive contact between surfaces. The result? A rock-solid bond that even Thor would be proud of.

Once fully cured, Titebond Hide Glue becomes a force to be reckoned with. It can withstand heat, solvents, and moisture like a champ. That’s why it’s a go-to choice for woodworking projects that require long-term durability.

Remember to store your Titebond Hide Glue properly to maintain its effectiveness. Keep it in a cool, dry place and seal it tightly to prevent moisture absorption or evaporation. And before you embark on your next bonding adventure, check the expiration date on the packaging to ensure you’re using fresh glue.

Long-Term Performance of Titebond Hide Glue

In this pursuit, Titebond Hide Glue shines as the ultimate solution that combines strength, durability, and reliability like no other.

Resisting the Elements:

Titebond Hide Glue boasts exceptional resistance to moisture, setting it apart from other options. Whether your masterpiece graces an indoor space or an outdoor patio, this glue remains steadfast even in damp conditions. It defies water and humidity, maintaining its strength and integrity, ensuring your creations withstand the test of time.

Temperature? No Problem.

Extreme temperature changes can wreak havoc on weaker glues, but not on Titebond Hide Glue. This remarkable adhesive thrives in scorching heat and freezing cold alike, refusing to lose its adhesive properties. Your wooden masterpieces will stay strong and intact, regardless of the challenging weather conditions they face.

The Secret Ingredient:

What gives Titebond Hide Glue its impressive long-term performance? It’s all thanks to its composition. Crafted from animal collagen, this glue forms a bond that is not only robust but also flexible. It effortlessly withstands stress, movement, and frequent use without breaking a sweat – or a joint. So go ahead and put your woodworking projects through their paces – Titebond Hide Glue is up for the challenge.

Reversibility for Repairs:

Life happens, and sometimes we need to disassemble or modify our woodworking projects. Luckily, Titebond Hide Glue is reversible. This means that if you ever need to make repairs or adjustments down the road, you can easily undo the bond created by this glue. It’s like having a safety net for your creations, allowing for flexibility and adaptability.

Proper Application for Optimal Results:

To unleash the full potential of Titebond Hide Glue, proper application and curing time are essential. Follow the manufacturer’s instructions carefully, paying attention to temperature, humidity, and clamping time. By doing so, you’ll ensure that the glue fully cures, creating an unbreakable bond that will stand the test of time.

Testing the Strength of Joints Bonded with Titebond Hide Glue

In this section, we will delve into the various methods used to test the strength of joints bonded with Titebond Hide Glue. By exploring these methods and understanding the factors that influence their results, readers will gain a comprehensive understanding of this powerful woodworking adhesive.

Methods of Testing:

Stress Test:

The stress test subjects the joint to a specific amount of pressure or force, assessing its stability and resistance to deformation. This method provides insight into how well the adhesive can withstand external stress and strain without compromising the joint’s integrity.

Shear Test:

The shear test applies a twisting or pulling force to the joint, measuring its strength against shearing forces commonly encountered in woodworking applications. This test highlights the adhesive’s ability to resist these forces and maintain a strong bond.

Factors Influencing Results:

Type of Wood:

Different wood species possess varying densities and surface characteristics that impact joint strength. Hardwoods generally offer better bonding surfaces due to their higher density and tighter grain structure, resulting in stronger joints.

Surface Preparation:

Proper surface preparation is crucial for achieving robust bonds. Surfaces must be clean, dry, and free from contaminants such as dust or oil. Roughening or scoring the surface enhances adhesive penetration and increases bond strength.

Application Technique:

The application technique significantly affects bond strength. Applying an even layer of glue, ensuring proper coverage on both surfaces, and using adequate clamping pressure are essential factors that directly influence joint strength.

Qk11FJMLUUc” >

Conclusion

In conclusion, Titebond Hide Glue is the ultimate adhesive for woodworking projects that demand long-lasting strength. Made from a blend of animal collagen and water, this traditional glue boasts exceptional bonding properties and reversibility, setting it apart from other options.

When stored in a cool, dry place, Titebond Hide Glue can endure for years on end. However, once opened, it’s best to use the glue within a year to guarantee optimal performance. Exposure to air can gradually deteriorate its adhesive qualities, so be sure to tightly seal the glue in airtight containers or bottles.

Don’t forget that external factors like temperature, humidity, wood type, and moisture levels can also influence how long Titebond Hide Glue lasts. By ensuring proper storage conditions and applying the glue with precision, you’ll maximize its shelf life while achieving bonds that withstand the test of time.

One of the standout features of Titebond Hide Glue is its ability to adapt to natural movements and fluctuations in wood without cracking or breaking. This flexibility ensures durability over time—a crucial characteristic for any woodworking project.

All things considered, Titebond Hide Glue is an adhesive that transcends generations with its unwavering strength and versatility. Whether you need a bond that lasts or one that can be easily disassembled or repaired when necessary, this reliable glue has got you covered.