Get ready for another wild ride as we delve into the captivating world of glue. Today, we’re tackling the burning question on everyone’s minds: just how long does it take for this sticky wonder to harden?

Whether you’re a crafty creator, a repair guru, or just someone who loves sticking things together (no judgment here), you know that waiting game can be nerve-wracking. But fear not, my friends. In this post, we’ll unravel the mysteries behind glue hardening and arm you with some essential tips to speed up the process.

From lightning-fast super glues to patient-as-a-saint wood glues, we’ll explore what makes each one tick and reveal their secret curing times.

Armed with this knowledge, you’ll be able to plan your projects like a pro and bid farewell to endless waiting.

So, buckle up and get ready for some mind-blowing revelations as we uncover the truth about glue hardening. Are you ready? Let’s dive in.

Types of Glue and Hardening Time

Contents

Glue is a fascinating substance that has the power to bond materials together. However, not all glues are created equal. Each type of glue possesses unique properties and requires a specific hardening time to achieve its maximum strength.

In this article, we will delve into the world of glue, exploring the different types available and their respective hardening times. Whether you’re a crafting enthusiast or a DIY guru, read on to discover which glue is the perfect match for your project.

White Glue: Crafty and Reliable

White glue, also known as school glue or PVA glue, is a versatile adhesive that finds its place in crafts and general household use. It’s like a superhero lurking in your craft drawer.

When using white glue, it’s important to exercise patience as it typically takes around 24 hours to fully harden and unleash its full bonding power.

So, whether you’re creating a beautiful paper craft or mending a broken vase, give white glue the time it needs to work its magic.

Super Glue: The Flash of Adhesives

Super glue is the Flash of the glue world. It’s famous for its lightning-fast drying time. Within seconds, this adhesive can bond materials together, creating an immediate hold. But don’t be fooled by its quick-drying abilities.

While super glue may appear dry on the surface, it can take up to 24 hours to reach its full strength. So, if you’re fixing a broken toy or crafting delicate jewelry, exercise patience and let super glue become super strong.

Epoxy Glue: The Dynamic Duo

Epoxy glue is like Batman and Robin – a dynamic duo that saves the day. This adhesive consists of two components – a resin and a hardener – that must be mixed together before application. Once mixed, epoxy glue takes several hours to fully harden and cure.

The exact drying time can vary depending on the brand and product instructions, so make sure to follow them diligently. Epoxy glue is perfect for bonding metal, plastic, and even wood.

Wood Glue: The Carpenter’s Best Friend

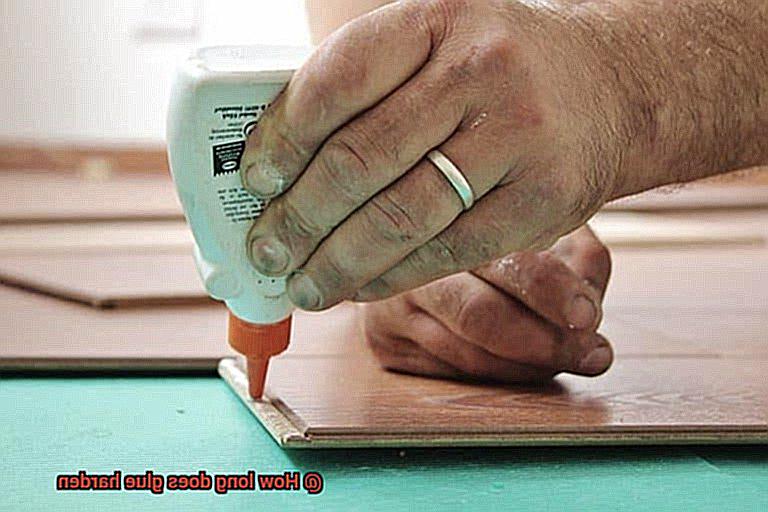

Wood glue is a carpenter’s secret weapon. It’s specially designed for bonding wood surfaces and creating sturdy joints. Like a patient friend, wood glue takes around 24 hours to fully cure and develop its maximum strength.

So, whether you’re building a wooden masterpiece or repairing furniture, give this glue the time it needs to unleash its full potential.

Contact Cement: The Mighty Hulk of Adhesives

Contact cement is like the Hulk of glues – strong and ready for heavy-duty tasks.

This adhesive is commonly used for bonding large surfaces, such as laminate countertops or flooring. While it dries relatively quickly, usually within 15 minutes to an hour, it can take up to 24 hours for the complete hardening process.

Wood Glue

Wood glue is a remarkable substance specifically formulated for bonding wood surfaces together. Whether you’re engaged in a woodworking project, constructing furniture, or involved in construction work, wood glue is the ultimate adhesive solution. But how does it actually work? Let’s dive deeper into the world of wood glue.

When it comes to wood glue, two main factors play a significant role in its drying time: temperature and humidity. Let’s start with temperature. Heat is the secret weapon of wood glue. Higher temperatures accelerate the drying process, allowing the glue to set faster.

So if you’re working in a toasty environment, rejoice. Your glue will dry in no time. On the other hand, cooler temperatures can slow things down, so if you find yourself gluing in a chilly workshop, be prepared for a slightly longer wait.

Now let’s talk about humidity. Wood glue is sensitive to moisture in the air, meaning humidity levels can affect the drying process. Low humidity levels speed up drying, while high humidity levels slow it down. If you’re in a dry climate, you’ll witness your wood glue harden more quickly. However, if you’re working in a humid area, exercise some patience.

To achieve exceptional results with wood glue, ensure an even layer of glue is applied to both surfaces being bonded. This guarantees a robust and uniform bond. And don’t forget to clamp the pieces together firmly after applying the glue. This maintains proper alignment and pressure for superior adhesion.

However, here’s the crucial part – even though wood glue may appear dry on the surface within 30 minutes to an hour, fully curing is essential before subjecting the joint to stress or load-bearing activities. Rushing this process can result in weak bonds that compromise your project’s integrity. So exercise patience and give your wood glue the time it needs to reach maximum strength.

Super Glue

With its lightning-fast curing time and formidable bonding strength, Super Glue is the go-to adhesive for quick fixes and instant repairs.

The secret behind Super Glue’s speedy curing process lies in the chemical reaction between its cyanoacrylate molecules and the moisture in the air. It’s a match made in bonding heaven. However, it’s essential to remember that clean and dry surfaces are crucial for a successful bond. Moisture can disrupt the curing process and weaken the bond, so make sure to prep your surfaces properly.

But let’s talk about time. Super Glue forms an initial bond within seconds of application, but don’t be fooled by its rapid performance. To achieve its maximum strength, it’s best to give it a minimum of 24 hours to fully cure. Patience is key when working on projects that will endure stress or load-bearing situations – give that bond time to reach its full potential.

Now, let’s delve into the factors that influence curing time. Temperature, humidity, and the materials being bonded all play significant roles. Generally, warmer temperatures expedite the curing process, while cooler temperatures may require a bit more waiting time. Low humidity levels are also advantageous for quick drying, but in humid areas, exercising patience is necessary.

In cases where you need an extra boost in curing time, accelerators or activators can come to the rescue. These magical products create an ideal environment for the glue to set, promoting faster curing. They are particularly useful when working with porous materials or in low-humidity conditions.

Epoxy Glue

Epoxy glue is a formidable adhesive known for its strength and versatility. Whether you’re working on construction projects, repairing furniture, or creating artwork, epoxy glue is a trusted choice. However, achieving optimal results requires understanding the factors that influence its hardening time. In this article, we will explore the world of epoxy glue, diving into how temperature, humidity, and adhesive layer thickness impact its curing process.

Temperature: A Catalyst for Cure Time

Temperature plays a significant role in epoxy glue’s hardening time. Warmer temperatures accelerate the curing process, while colder temperatures slow it down. The chemical reaction between the resin and hardener is exothermic, releasing heat. Consider two scenarios:

- Quick Fix in Summer: Repairing a broken ceramic mug on a sunny summer day means faster curing due to the higher ambient temperature. Sip your favorite beverage from the mug sooner.

- Patience in Winter: Picture yourself fixing a wooden chair leg in the middle of winter. The colder temperature slows down the curing process, demanding patience for a strong bond.

Humidity: Moisture Management Matters

Humidity affects epoxy glue’s hardening time as it relies on moisture in the air for the chemical reaction to occur:

- Low Humidity Conditions: Dry environments or heated indoor spaces during winter can slow down curing due to lack of moisture. Some epoxy glues offer accelerators or activators to introduce moisture for faster curing.

- High Humidity Conditions: Conversely, high humidity speeds up curing as moisture facilitates the chemical reaction. However, excessive humidity can weaken the bond, requiring a careful balance.

Adhesive Layer Thickness: Thin vs. Thick

The thickness of the adhesive layer also impacts hardening time:

- Thin Layers: Applying epoxy glue thinly exposes more surface area to air, allowing quicker moisture absorption and faster curing. Ideal for delicate materials or quick fixes.

- Thick Layers: Thicker layers take longer to cure due to limited exposure to air and moisture. Patience is key as the epoxy glue slowly cures from the outer layer towards the center for a strong bond.

Factors That Can Influence Hardening Time

In this article, we will delve deep into the factors that can influence the hardening time of glue.

By examining the type of glue, temperature, humidity, substrate material, application thickness, and mixing ratios, we will gain a comprehensive understanding of what affects the drying and hardening process.

Type of Glue:

Different types of glues possess unique characteristics that contribute to their varying hardening times. For instance, cyanoacrylate (super glue) sets within seconds, while epoxy glues may require hours or even days to reach full cure.

Understanding the properties and capabilities of different glue types empowers users to select the most suitable adhesive for their specific project requirements.

Temperature:

Temperature plays a crucial role in the hardening process of glue. Higher temperatures accelerate drying, while lower temperatures slow it down. Extreme temperatures can compromise adhesive performance and weaken bonds.

It is imperative to ascertain the optimal temperature range recommended by the manufacturer for achieving the desired results.

Humidity:

The level of humidity in the surrounding environment significantly impacts the hardening time of glue. Higher humidity levels prolong drying as excess moisture impedes evaporation, while low humidity speeds up the process.

Some glues are specifically formulated to perform better in specific humidity conditions, making it essential to consider this factor when selecting an adhesive.

Substrate Material:

The material onto which glue is applied can exert a profound influence on hardening time. Porous materials like wood or paper absorb moisture from the glue, resulting in longer drying times.

Conversely, non-porous materials like glass or metal facilitate faster drying. Using the appropriate glue for specific substrates ensures optimal curing times and enhances bond strength.

Application Thickness:

The thickness of the glue layer has a direct impact on drying time. Thicker layers require more time to dry as a larger amount of moisture needs to evaporate. Adhering to the manufacturer’s instructions regarding the recommended application thickness ensures optimal drying and hardening results.

Mixing Ratios (for certain glues):

Certain glues, such as two-part epoxy adhesives, necessitate precise mixing ratios of two components prior to application. Deviating from these ratios can impede the chemical reaction responsible for hardening, leading to incomplete drying or prolonged curing times. Accurate measurement and meticulous mixing are crucial for achieving successful bonding outcomes.

Temperature and Humidity Levels

Glue is a remarkable adhesive that serves a multitude of purposes, from bonding delicate crafts to constructing sturdy buildings. However, have you ever wondered why glue takes varying amounts of time to harden? The answer lies in the captivating relationship between temperature and humidity levels.

In this blog post, we will delve into the intricate interplay of these environmental factors and how they influence the hardening process of glue.

Temperature: Catalyzing Quick Bonding

Temperature plays a pivotal role in the glue hardening process. Each type of glue has an optimal temperature range for curing, typically indicated on the packaging or in the manufacturer’s instructions. Higher temperatures hasten drying, facilitating rapid bond formation.

Yet, caution must be exercised, as excessively high temperatures can weaken bonds or render the glue brittle.

Conversely, lower temperatures impede curing, prolonging the time required for complete hardening.

Humidity: Dampening Drying Time

Humidity levels also impact glue hardening. In humid conditions, airborne moisture interferes with the drying process, prolonging curing time. This occurs because moisture impedes the evaporation of solvents or water content in glue, which is essential for hardening. Different glues exhibit varying sensitivities to humidity levels, necessitating specific conditions for optimal bonding.

Achieving Optimal Results

To ensure proper glue hardening, it is imperative to work in an environment with controlled temperature and humidity levels. This can be accomplished by operating in a well-ventilated area with moderate temperature and humidity control. However, when faced with extreme conditions, precautions can be taken. Utilizing a dehumidifier or air conditioner helps reduce humidity levels, while heat sources like hairdryers or cautiously used heat guns expedite hardening in colder temperatures.

Striking the Perfect Balance

While higher temperatures or lower humidity levels accelerate hardening, it is crucial to strike a balance. Excessive heat or extremely low humidity can compromise bonding strength and overall durability. Thus, understanding the optimal conditions for specific glue types is essential to achieve reliable and lasting bonds.

Following Manufacturer Instructions

First and foremost, let’s talk about drying time. Different glues have different recommended drying times. Some may dry in a jiffy, while others may require a bit more patience. By knowing the specific drying time for your glue, you can avoid any premature bonding disasters and ensure a strong and lasting connection between your materials.

But that’s not all. Temperature and humidity also play a vital role in how well your glue performs. Extreme temperatures or high humidity can throw off the drying process, resulting in a weaker bond. So, it’s important to take note of the ideal temperature and humidity conditions stated in the instructions. Your glue will thank you later.

Now, let’s move on to application. The manufacturer’s instructions might include guidelines on how much glue to use or its recommended thickness. Following these guidelines ensures that you achieve that perfect balance between too little and too much adhesive. You want just enough to create a strong bond without any excess gooey mess.

Here’s a pro tip for you: resist the urge to rush the drying process by applying excessive heat or force. Patience is key. Trust me, waiting for that glue to fully harden naturally will save you from potential bonding mishaps or damage to your materials.

And remember, if you find yourself scratching your head over any aspect of the instructions, don’t fret. Contacting the manufacturer directly is an excellent move. They’re there to provide specific guidance and address any concerns you may have.

Tacky or Sticky Feel After Hardening

Glue possesses the magical ability to bond materials together, but sometimes it leaves us grappling with a sticky situation. That infuriating moment when you think your glue has solidified, only to discover it still clings to your fingers.

Today, we embark on a journey to uncover the secrets behind this perplexing phenomenon and arm you with effective strategies to conquer the stickiness head-on.

The Type of Glue:

Not all glues are born equal, my friends. Take, for instance, the infamous PVA glue. This type of adhesive is notorious for drying with a persistent tacky feel. When PVA glue hardens, it forms a flexible film that retains its stickiness. In contrast, glues like epoxy or super glue set into a firm, non-tacky texture that defies any sticky expectations.

Environmental Conditions:

Just as we humans are influenced by our surroundings, glue too succumbs to environmental factors during the drying process. Humidity and temperature play significant roles in determining the final texture of your adhesive masterpiece.

High levels of humidity can impede drying and result in a frustratingly sticky finish. So, if you find yourself working amidst humid conditions, prepare yourself for potential tackiness.

Solutions to the Stickiness:

For those plagued by hardened but unwaveringly sticky glue, fret not. We offer you tried-and-true methods to combat this sticky conundrum. One solution involves applying a thin layer of clear varnish or sealant over the dried glue.

This acts as a shield, sealing in the stickiness and bestowing upon you a smoother finish. Another effective technique involves gently sanding the surface using fine-grit sandpaper, which eradicates excess stickiness and grants a more gratifying texture.

Choosing the Right Glue:

If you aspire to achieve a non-tacky finish from the outset, consider handpicking glues specially formulated for this purpose. Crafters and woodworkers, rejoice. Some glues cater to your needs by maintaining a level of flexibility or adhesion even after drying. Opting for glues that dry clear, smooth, and non-tacky will spare you any post-hardening surprises.

Patience is Key:

Remember, my fellow glue enthusiasts, patience is a virtue when it comes to drying. Embrace the wisdom bestowed upon you by the glue gods and adhere diligently to the manufacturer’s instructions. Grant the adhesive ample time to solidify completely before handling or applying pressure. Different types of glues boast varying drying times, so exercise caution and peruse those instructions meticulously.

Waiting Until Fully Cured Before Applying Stress or Loads

Today, I will share crucial information about glue that will help you achieve the best results. We’ll dive into the topic of waiting until glue is fully cured before applying stress or loads, and why this step is so important in your adhesive adventures.

Glue is all about creating that perfect bond that can withstand any stress or load. But did you know that applying stress or loads to glue before it’s fully cured can weaken or even break the bond? That’s right. The curing process is what transforms glue from a liquid state to a solid state, forming those strong bonds we all desire. So, let’s get into the nitty-gritty details.

First things first, different types of glue have different curing times. Some may only take a few minutes to cure, while others may take hours or even days. It’s crucial to consult the manufacturer’s instructions or product specifications to determine the specific curing time for the glue you’re using. Remember, patience is key.

Now, let’s talk about why waiting for full curing is so important. When you wait for glue to fully cure, it develops its maximum bonding strength. This means that if you jump the gun and apply stress or loads too soon, you risk compromising the structural integrity of the glued surfaces. And nobody wants a failed bond, right?

External factors can also influence the curing time of glue. Temperature, humidity, and ventilation all play significant roles here. Higher temperatures generally speed up the curing process, while lower temperatures slow it down. Similarly, higher humidity levels can extend curing times, while lower levels can speed it up. So keep these factors in mind when planning your adhesive projects.

Now that we understand the importance of waiting until glue is fully cured let’s talk about how long we should wait. The waiting time can vary depending on the type of glue and the specific application. For quick-drying glues, waiting a few minutes may be sufficient, but for more complex applications or stronger adhesives, waiting several hours or even overnight may be necessary. Remember, patience is a virtue.

U0hhFjjW5EU” >

Conclusion

The hardening time of glue can vary depending on the type and brand you are using. Generally, it takes anywhere from a few minutes to several hours for glue to fully harden. However, it’s important to note that different factors such as temperature, humidity, and the materials being glued together can affect this process.

In some cases, fast-drying glues can set in as little as 30 seconds, providing quick and convenient bonding solutions. These types of glues are commonly used for small repairs or craft projects where immediate results are desired.

On the other hand, there are also slow-drying glues that require more time to fully harden. These glues are often used in woodworking or construction applications where strong and long-lasting bonds are necessary. It may take several hours or even overnight for these glues to reach their maximum strength.

During the hardening process, it’s essential to ensure that the glued surfaces remain undisturbed and properly aligned. Applying pressure or clamping the pieces together can help achieve a secure bond and improve overall drying time.

Moreover, it’s crucial to follow the manufacturer’s instructions for optimal results. Different glues have specific recommendations regarding application techniques, drying times, and curing conditions. By adhering to these guidelines, you can ensure that your glue hardens effectively and provides reliable bonding.

In conclusion, while there is no one-size-fits-all answer to how long glue takes to harden, understanding the characteristics of your chosen adhesive and considering external factors will help you achieve successful bonding outcomes.