Do you ever wonder how quickly PVA (polyvinyl alcohol) dissolves in water? As an expert, I’m thrilled to share with you some intriguing insights and information about this topic. Whether you’re a scientist, a curious student or just someone looking to learn something new, this blog post is for you.

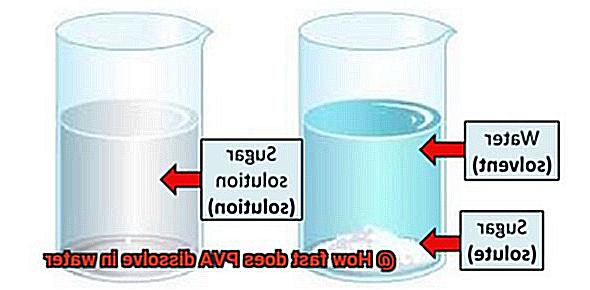

Let me start by telling you that PVA is a water-soluble polymer used in various applications such as adhesives, textiles and packaging. The speed at which it dissolves depends on several factors like concentration, temperature, pH levels and other substances present.

In this post, we’ll go deeper into the different factors that affect PVA’s dissolution rate in water and how you can manipulate them to control its breakdown speed. We’ll also explore some exciting applications of PVA such as its use in creating biodegradable plastics and as a coating for drug delivery systems.

So buckle up and join me on this adventure of learning and discovery as we explore the fascinating world of polymer science.

What is PVA?

Contents

Polyvinyl acetate, commonly known as PVA, is a synthetic polymer that is widely used in the manufacturing of various adhesives and coatings. This rubbery, odorless, and tasteless substance is water-soluble and was first discovered in Germany in 191It wasn’t until the 1930s when it started being used in the manufacturing of glue.

PVA is a versatile adhesive that can be used for many different purposes, including woodworking, paper crafts, and even bookbinding. What sets PVA apart from other adhesives is its ability to dry clear without yellowing over time, making it a popular choice for many. Additionally, PVA glue is non-toxic and easy to clean up with water, making it ideal for children’s crafts.

There are different types of PVA glue available on the market, such as white glue and school glue. White glue is usually thicker and stronger than school glue, which is designed for use in classrooms and for children’s crafts. Both types dissolve quickly in water, making them easy to clean up if spilled or if excess glue is applied.

However, several factors affect how fast PVA dissolves in water. The concentration of PVA in the water, temperature, and pH level can all affect the rate of dissolution. Higher concentrations and temperatures accelerate the dissolution process while acidic or alkaline solutions can cause PVA to break down more quickly. Therefore, it’s important to use distilled or deionized water with a neutral pH when testing the dissolution rate of PVA.

Factors Affecting the Dissolution Rate of PVA

PVA, a synthetic polymer widely used in adhesives, coatings, and films, has a complex dissolution process that depends on several factors. Let’s explore them in detail.

Temperature is the first factor that affects PVA’s dissolution rate. As the temperature increases, so does the kinetic energy of water molecules, breaking the hydrogen bonds between PVA molecules more easily. If you want to dissolve PVA quickly, heat up that water.

The second factor is pH. Low pH values cause PVA molecules to protonate and become less water-soluble. In contrast, high pH values cause PVA molecules to deprotonate and become more water-soluble. Keep that pH level in check to optimize your PVA’s dissolution rate.

Molecular weight is also critical to PVA’s dissolution rate. Higher molecular weight PVA has stronger intermolecular forces and is less soluble in water than lower molecular weight varieties. For faster dissolution rates, choose lower molecular weight varieties.

The degree of hydrolysis of PVA is another important factor. The extent to which the PVA molecule has been broken down into its constituent parts determines its polarity and water solubility. Higher degrees of hydrolysis mean more polar and water-soluble molecules that dissolve more easily in water.

Finally, concentration also plays a role in PVA’s dissolution rate. As the concentration of PVA in solution increases, the available surface area for water to interact with decreases, slowing down the dissolution rate. Therefore, for faster dissolution rates, use a lower concentration.

Concentration of PVA in Water

To use an analogy, it’s like cooking pasta – the more you add to the pot, the longer it takes to cook. But let’s dive deeper into this topic.

Temperature is a crucial factor affecting PVA solubility. Just as hot water cooks pasta quicker, increasing the temperature of the water can speed up the PVA dissolution process. At 50°C, a 10% PVA solution can dissolve within a minute, while a 20% solution takes only five minutes. So, if you’re in a rush, heating up your water is key.

Additionally, pH levels have a significant impact on PVA solubility. Acidic or neutral solutions dissolve PVA more easily than alkaline solutions. If you try to dissolve PVA in a basic solution like soap or detergent, you might face difficulty getting it to dissolve completely.

However, other factors also affect the dissolution rate of PVA. Stirring or agitation of the solution, particle size, and other substances present in the solution can all influence how quickly PVA dissolves.

Temperature of Water

PVA glue is a water-based adhesive that is widely used in various crafts, woodworking, and more. When mixed with water, it dissolves to create a solution that can be applied to different surfaces. And temperature plays a crucial role in this process.

The warmer the water, the faster PVA glue will dissolve. This is because heat increases the molecular motion of water molecules, which in turn accelerates the rate of diffusion of the PVA molecules. It’s like boiling pasta – the hotter the water, the faster it cooks.

However, using extremely hot water can have a negative impact on the glue. It can break down or become too thin, which can affect its adhesive properties. Therefore, it’s recommended to use room temperature water (about 20-25°C) for dissolving PVA glue. This provides a good balance between speed and effectiveness.

But what if you’re dealing with particularly thick or stubborn glue? Warming up the water slightly can help speed up the dissolution process. However, it’s crucial to avoid using boiling water as it can damage the glue.

Temperature isn’t the only factor to consider when working with PVA glue. Other factors such as concentration, surface type, and application method can also affect its performance. For best results, follow best practices for handling and using PVA glue.

To sum it up, temperature does affect how quickly PVA glue dissolves in water, but it’s just one factor to consider. By using room temperature water and following best practices for handling PVA glue, you can ensure optimal results every time.

pH Level of Water

The pH scale ranges from 0 to 14, with 7 being neutral. pH levels below 7 are acidic, and levels above 7 are alkaline. To dissolve PVA glue effectively, it’s best to use water with a pH level between 6.5 to 7.5, which falls within the neutral range.

Using water that is too acidic or too alkaline can cause problems when dissolving PVA glue. If the water is too acidic, the glue may break down and lose its adhesive properties, rendering it ineffective. Conversely, if the water is too alkaline, the glue may become sticky and clump together, making it harder to dissolve.

To ensure you’re using water with the right pH level, you can use a pH testing kit to measure your water’s acidity or alkalinity. If your water falls outside of the optimal range, you can adjust it by adding small amounts of baking soda to raise the pH or vinegar to lower the pH.

It’s worth noting that using room temperature water is crucial when working with PVA glue. Just like pasta, high temperatures can cause the glue to become ineffective.

Using Distilled or Deionized Water with a Neutral pH

Let’s start with the basics. PVA is a water-soluble polymer used as a glue or adhesive in various applications. When testing its dissolution rate in water, it’s essential to eliminate any potential sources of interference that could affect the results.

This is where distilled or deionized water comes into play. Distilled water is created by boiling water and collecting the steam, leaving behind any impurities such as minerals, bacteria, or chemicals. Deionized water, on the other hand, goes through an ion exchange process that removes all charged ions from the water, including mineral ions. Both forms of water are incredibly pure and free of contaminants.

Using distilled or deionized water with a neutral pH ensures that there are no acidic or basic conditions that could alter the dissolution rate of PVA. By eliminating any factors that could affect the dissolution rate, accurate and reliable results can be obtained.

To summarize, here are some key reasons why using distilled or deionized water with a neutral pH is crucial when testing PVA dissolution rates:

- It eliminates any potential sources of interference, such as impurities or minerals in regular tap water.

- It ensures that there are no acidic or basic conditions that could alter the dissolution rate of PVA.

- It provides pure and neutral water, which is essential for obtaining accurate and reliable results.

Accelerating the Dissolution Process

Whether you’re working on a project that requires a quick drying time or simply need to dissolve a large amount of PVA quickly, there are a few ways to accelerate the dissolution process.

One effective method is to increase the temperature of the water. While PVA is soluble in water at room temperature, heating the water can speed up the process. However, it’s important to note that excessive heat can degrade the PVA and make it less effective. Therefore, it’s recommended to use warm water instead of hot water when attempting to accelerate dissolution.

Another way to speed things up is by increasing the surface area of the PVA. Breaking up the PVA into smaller pieces or using a powdered form allows more water molecules to come into contact with the PVA, which accelerates dissolution.

Agitation also plays an important role in accelerating the dissolution process. Whether you’re stirring or shaking, moving the mixture around constantly brings fresh water molecules into contact with the PVA. This helps break down the bonds between polymer chains and speeds up dissolution.

Last but not least, adding an alkaline substance like baking soda to the water can help accelerate dissolution. By increasing the pH of the water, the alkaline substance helps break down polymer chains in the PVA.

Slowing Down the Dissolution Process

Trying to slow down the dissolution process of PVA glue can be tricky, but luckily there are several effective methods you can try.

If you’re looking for a simple solution, start by using cold water instead of warm or hot water when dissolving the glue. The colder temperature slows down the movement of water molecules, making it more difficult for them to break apart the PVA molecules and ultimately slowing down the dissolution process.

Another method to consider is adding a thickener to your PVA glue. Thickening agents increase the viscosity of a liquid, making it thicker and less likely to flow. This makes it more difficult for water molecules to penetrate and break apart the PVA molecules, effectively slowing down the dissolution process.

Mixing PVA glue with a substance that is less soluble in water than PVA can also help slow down the dissolution process. Cornstarch is a great option, as it is less soluble in water than PVA and can help thicken the mixture.

Lastly, reducing the surface area of the PVA glue can be effective in slowing down the dissolution process. You can achieve this by applying a thicker layer of glue or using a surface that has been pre-treated with a sealant or primer.

RTS_hPXzrBk” >

Conclusion

To wrap up, PVA (polyvinyl alcohol) is a versatile polymer that dissolves in water and finds use in many applications such as adhesives, textiles, and packaging. However, the speed at which it dissolves depends on various factors like concentration, temperature, pH levels, and other substances present.

Temperature is a critical factor affecting PVA solubility. While higher temperatures can accelerate dissolution, excessive heat can also degrade the PVA and affect its effectiveness. Optimal results are achieved by using room temperature water.

The pH level of the water also plays a significant role in PVA solubility. Maintaining a neutral pH between 6.5 to 7.5 ensures effective dissolution of PVA glue. Using distilled or deionized water guarantees accurate and reliable results.

Factors like surface area, agitation, thickening agents, and other substances present can either speed up or slow down the dissolution process of PVA glue.

As an expert in polymer science, I hope this blog post has provided you with intriguing insights into how fast PVA dissolves in water.