Looking to give your plastic chair a touch of elegance or transform a plain storage bin into a stylish statement piece? Adhering fabric to plastic can breathe new life into everyday items. Don’t worry, it’s easier than you think. We’ve got you covered with a comprehensive guide to make your project a breeze.

Materials:

- Plastic surface: chair, storage bin, or any other object

- Suitable fabric: lightweight cotton, polyester, or blend

- Adhesive: fabric glue or heavy-duty spray adhesive

- Scissors or rotary cutter

- Measuring tape or ruler

- Optional: upholstery-weight thread and needle for added durability

Safety Precautions:

- Ensure good ventilation when using adhesive, especially in confined spaces.

- Work in a well-lit area to avoid accidents while cutting fabric.

- Protect surfaces with newspapers or a drop cloth when using spray adhesive.

Step-by-Step Guide:

- Preparation: Thoroughly clean the plastic surface to remove dirt, grease, or dust that could affect adhesion.

- Measuring and cutting: Measure the area you want to cover with fabric. Add extra inches for allowances. Trim the fabric using scissors or a rotary cutter according to measurements.

- Applying adhesive: Follow the manufacturer’s instructions and apply fabric glue or spray adhesive evenly onto the plastic surface. If using fabric glue, wait for it to become tacky; if using spray adhesive, follow curing time recommendations.

- Positioning the fabric: Gently lay the cut fabric on the adhesive starting from one end and smoothing it down as you go across the surface. Avoid wrinkles or bubbling by being careful.

- Bonding: Apply pressure along the entire fabric area for a strong bond between the fabric and plastic surface. Use a roller or press down firmly with your hands.

- Finishing touches: Neatly trim any excess fabric along the edges using scissors or a rotary cutter. For added durability, sew a topstitch along the edges using upholstery-weight thread and needle.

- Drying time: Allow the adhesive to cure according to the manufacturer’s instructions, which could range from a few hours to overnight. Avoid moving or using the object until the adhesive is fully dry.

Now that you have all the steps at your fingertips, go ahead and give your plastic items a fabulous fabric makeover.

What is Fabric Glue and How Does it Work?

Contents

- 1 What is Fabric Glue and How Does it Work?

- 2 Benefits of Using Fabric Glue

- 3 Double-Sided Tape: An Easy and Quick Solution

- 4 Advantages of Using Double-Sided Tape

- 5 Spray Adhesive: Another Option for Bonding Fabric to Plastic

- 6 Benefits of Using Spray Adhesive

- 7 Heat Bonding: A Strong Bond with Heat Activated Adhesives

- 8 Sewing: Ideal for Heavy or Thick Fabrics

- 9 Conclusion

Fabric glue is a versatile adhesive that allows you to bond fabric to plastic surfaces with ease. Whether you’re repairing a torn garment, creating fabric-based decorations, or upholstering furniture, fabric glue can provide a quick and convenient solution without the need for sewing or stitching.

One of the key properties of fabric glue is its adhesive strength. It is formulated to create a strong and durable bond between the fabric and plastic materials. This allows the bonded fabric to withstand regular use and movement without compromising the adhesion. However, it’s important to note that the adhesive strength may vary depending on the specific brand and type of fabric glue used.

Fabric glue is typically a liquid adhesive that dries clear and flexible. This means that once the glue is applied and dried, it becomes virtually invisible, allowing the fabric to maintain its original appearance. The flexibility of fabric glue is crucial, especially when working with fabrics that require some degree of stretch or movement, such as clothing or upholstery materials.

When applying fabric glue, it’s essential to ensure that both the fabric and plastic surfaces are clean and free from any dust or debris. This helps to maximize the bond strength and longevity. Once the surfaces are clean, the glue can be applied directly onto the plastic surface in thin and even layers. It’s important not to apply too much glue, as this can result in excess seepage or uneven bonding.

After applying the glue, firmly press the fabric onto the plastic surface, making sure there are no air bubbles or wrinkles. The bond between the fabric and plastic will start to form within minutes, but it’s recommended to let the glue dry completely for a specified period. This can range from a few hours to overnight, depending on the specific brand and type of fabric glue used.

Fabric glue has several advantages over other methods of bonding fabric to plastic. Firstly, it provides a quick and easy solution for attaching fabric without the need for specialized equipment or sewing skills. This makes it accessible to a wide range of users, from beginners to professionals. Additionally, fabric glue creates a flexible bond that allows the fabric to move and stretch without compromising the adhesion. This is particularly important when working with fabrics that require some degree of flexibility, such as clothing or upholstery materials.

Benefits of Using Fabric Glue

Fabric glue is a versatile, strong, and user-friendly adhesive that offers numerous benefits when it comes to sticking fabric to plastic. Whether you’re working on a craft project, repairing a garment, or creating accessories, fabric glue can be a game-changer. Let’s explore the advantages of using fabric glue in more detail.

First and foremost, fabric glue is incredibly versatile. It can be used to attach fabric to various types of plastic, including PVC, acrylic, and polypropylene. No matter what kind of plastic you’re working with, fabric glue has got you covered.

One of the biggest advantages of using fabric glue is its strong and durable bond. Once applied, it creates a permanent connection that can withstand regular wear and tear. Say goodbye to loose threads and weak stitches. With fabric glue, your fabric will stay firmly in place.

But that’s not all. Unlike other methods like sewing or using a hot glue gun, fabric glue leaves no visible stitches or messy residue. It provides a seamless finish that is perfect for projects where aesthetics are important. Your finished product will look clean and professional.

Using fabric glue is also a breeze. You don’t need any special skills or expertise to use it. Simply apply the glue onto the fabric and press it onto the plastic surface. The adhesive will dry clear and flexible, ensuring a seamless finish.

Another fantastic feature of fabric glue is its ability to withstand washing and dry cleaning. Fabrics attached with fabric glue can be safely laundered without the risk of the bond breaking or weakening. This makes it ideal for clothing or accessories that need regular cleaning.

Fabric glue is also resistant to moisture and humidity, making it suitable for outdoor or water-resistant projects. Whether you’re working on a raincoat or a beach bag, fabric glue can withstand exposure to rain, snow, or high humidity levels without deteriorating.

And here’s the best part – fabric glue is often non-toxic and safe for use on fabrics that come into contact with skin. So you can confidently attach fabric to plastic items that may be used in close proximity to the body, like clothing or accessories.

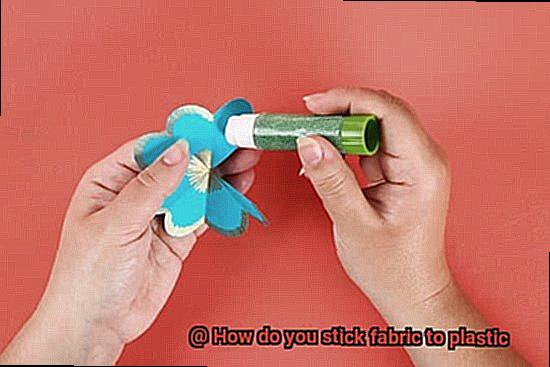

With fabric glue, you have a wide range of options to choose from. It comes in liquid, gel, and stick formats, allowing you to pick the type that best suits your project needs.

Last but not least, fabric glue offers a cost-effective solution for attaching fabric to plastic. It is generally more affordable than other methods like sewing or using specialized adhesives. So you can save money while still achieving a strong and seamless bond.

Double-Sided Tape: An Easy and Quick Solution

Struggling with fabric that just won’t stay put on a plastic surface? Look no further than double-sided tape, the ultimate superhero adhesive for sticking fabric to plastic. With its seamless and durable bond, this versatile adhesive option is the quick and easy solution you’ve been searching for.

The magic of double-sided tape lies in its design. This adhesive wonder features sticky goodness on both sides, allowing it to adhere to both the fabric and the plastic surface simultaneously. It’s like having a trusty sidekick that never lets you down.

But before you dive headfirst into this adhesive wonderland, there are a few things to keep in mind. First, make sure both the fabric and plastic surface are clean and free from any dirt or debris. This ensures maximum adhesion and a bond that lasts longer than a superhero movie marathon.

Using double-sided tape is a breeze. Just three simple steps: cut, apply, and press. Cut the desired length of tape, apply it to the fabric, remove the backing from one side, and press the fabric onto the plastic surface firmly. Remember to apply pressure along the entire length of the fabric for an unbreakable bond. Voila. Your fabric is now securely attached to the plastic.

Now, let’s talk about some advantages of this solution:

- Convenience: Double-sided tape is easy to use and readily available. No need for messy glues or complicated sewing techniques.

- Temporary Fix: Perfect for projects that require a quick fix or when you need to remove the fabric later without damaging either material.

- Compatibility: Double-sided tape comes in various widths, lengths, and strengths, making it suitable for different types of fabrics and plastics.

- Strength: For heavier fabrics or larger pieces, opt for stronger or wider double-sided tape to ensure a rock-solid bond.

- Extra Reinforcement: Combine double-sided tape with other adhesive options like fabric glue or spray adhesive for an unbeatable bond.

It’s important to note that double-sided tape may not be suitable for all fabrics and plastics. Test a small area first to ensure compatibility. And remember, this superhero adhesive is a temporary solution, so use it wisely.

Advantages of Using Double-Sided Tape

Tackling the challenge of sticking fabric to plastic can be a daunting task, but fear not. There is a superhero adhesive that will save the day – double-sided tape. In this blog post, we will explore the many advantages of using double-sided tape, from its easy application and versatility to its residue-free removal and invisible bond.

Advantage 1: Easy Application

Double-sided tape makes sticking fabric to plastic a breeze. Say goodbye to sewing or messy glue applications. With double-sided tape, all you need to do is peel off the backing paper from both sides, press the fabric onto one side, and attach it to the plastic surface. This quick and hassle-free process saves you time and effort, allowing you to focus on unleashing your creativity.

Advantage 2: Versatility

Double-sided tape is a true jack-of-all-trades when it comes to sticking fabric to plastic. It works seamlessly with various types of fabrics, including cotton, polyester, nylon, and more. Additionally, it adheres well to different plastic surfaces like acrylic, PVC, and polycarbonate. This versatility opens up a world of possibilities for your projects, whether you’re creating stunning crafts or giving your home a fresh look.

Advantage 3: No Residue

Nobody likes a sticky mess left behind after removing adhesive. Luckily, double-sided tape is designed to leave little to no residue when removed from surfaces. When sticking fabric to plastic, this advantage ensures that neither material will be damaged or left with any sticky residue. So go ahead and experiment without worrying about long-term consequences – remove or reposition your fabric as much as you want.

Advantage 4: Invisible Bond

Creating a clean and seamless appearance is crucial for many projects. Unlike traditional glue methods that may leave visible marks or lines, double-sided tape creates an invisible bond between the fabric and the plastic surface. The tape remains hidden between the layers, resulting in a professional finish and aesthetic appeal that will impress even the most discerning eyes.

Advantage 5: Temporary or Permanent Fixation

Not all projects require a permanent bond. Double-sided tape offers flexibility by providing options for both temporary and permanent fixation. If you need to make frequent adjustments or want to use the fabric for a short period, opt for temporary tape. On the other hand, if durability is paramount and you want a long-lasting bond, choose permanent tape. The choice is yours.

Spray Adhesive: Another Option for Bonding Fabric to Plastic

In this blog post, we’ll explore the advantages of using spray adhesive as a convenient and effective solution. Whether you’re a DIY enthusiast or a professional, this versatile adhesive offers a hassle-free way to bond fabric to plastic.

Versatility:

Spray adhesive is your go-to option for various fabrics, from cotton to delicate silk. It also bonds well with different types of plastics such as PVC, acrylic, and polyethylene. This versatility makes it suitable for a wide range of projects and applications. Whether you’re working on upholstery, crafting, or repairs, spray adhesive has got you covered.

Ease of Use:

Spray adhesive is incredibly user-friendly. With its canister and nozzle design, you can easily create a fine mist by spraying the adhesive onto the desired surfaces. The adhesive dries quickly, saving you time and effort in achieving a strong bond between the fabric and plastic. No more struggling with traditional glues or sewing methods – spray adhesive provides a convenient alternative.

Instructions for Success:

To ensure optimal results, it’s essential to follow the manufacturer’s instructions. First, ensure both surfaces are clean and free from any dust or debris. Next, spray the adhesive evenly onto both the fabric and plastic surfaces, holding the canister about 6-8 inches away for an even application. Be sure to achieve good coverage on both surfaces. Finally, allow the adhesive to dry for the recommended amount of time without touching or moving the fabric and plastic. This drying period is crucial for proper bonding.

Strong Bond:

Spray adhesive creates a durable bond between fabric and plastic. Its strong bonding properties make it ideal for various projects and applications. Whether you’re upholstering furniture, creating crafts, or fixing broken plastic items, spray adhesive provides a reliable solution. Say goodbye to weak bonds and hello to a long-lasting connection between fabric and plastic.

Benefits of Using Spray Adhesive

It’s time to discover the benefits of using spray adhesive. This convenient and versatile solution offers a range of advantages that will make your projects a breeze.

First and foremost, spray adhesive is incredibly easy to apply. Unlike traditional glues that require brushes or spreading tools, spray adhesives come in aerosol cans that allow for quick and even distribution. With just a few sprays, you can cover a large area, saving you time and ensuring an even application.

But ease of use is just the beginning. Spray adhesives are also known for their strong bonding capabilities. Once applied, they create a durable bond between fabric and plastic that can withstand stress and movement. This is particularly important when working on projects that involve constant use or regular wear and tear.

Another advantage of spray adhesive is its versatility. Whether you’re working with lightweight or heavy fabrics, or different types of plastics such as PVC, acrylic, or polypropylene, there’s a spray adhesive available that can effectively adhere to these materials. This flexibility allows you to tackle a wide range of projects without worrying about whether the adhesive will work with your specific materials.

One of the most frustrating aspects of using adhesives is waiting for them to dry. Thankfully, spray adhesives have a quick drying time, allowing you to move on with your project without delays. This is especially beneficial for time-sensitive projects or when you need to proceed to the next step without waiting around.

When using spray adhesive, you can also expect minimal residue left behind on the fabric or plastic surface. Unlike some other adhesives that can leave clumps or smears, spray adhesives provide a clean and even application. This ensures a neat and professional finish to your project, without any unsightly marks or blemishes.

But what if you make a mistake or need to make adjustments? That’s where the repositionable feature of some spray adhesives comes in handy. With this feature, you can adjust the fabric placement even after it has been initially applied. This saves time and prevents mistakes, ensuring you achieve the desired result.

Lastly, spray adhesives are widely available. You can find them in most craft stores, hardware stores, and online retailers. With a wide range of brands and options to choose from, you can select a spray adhesive that best suits your specific needs and preferences.

Heat Bonding: A Strong Bond with Heat Activated Adhesives

Have you ever marveled at the seamless union of fabric and plastic, wondering how they stick together without a single stitch or seam? The secret lies in the remarkable technique known as heat bonding, powered by the incredible properties of heat activated adhesives. This method creates an unbreakable bond between fabric and plastic, making it the go-to choice for industries ranging from automotive to fashion, upholstery to manufacturing.

So, how does heat bonding work? Allow me to take you on a journey through the intricate details.

First and foremost, heat activated adhesives are specially crafted compounds that spring into action when exposed to heat. These adhesives typically come in the form of films or pellets, which can be effortlessly melted and applied to both fabric and plastic surfaces.

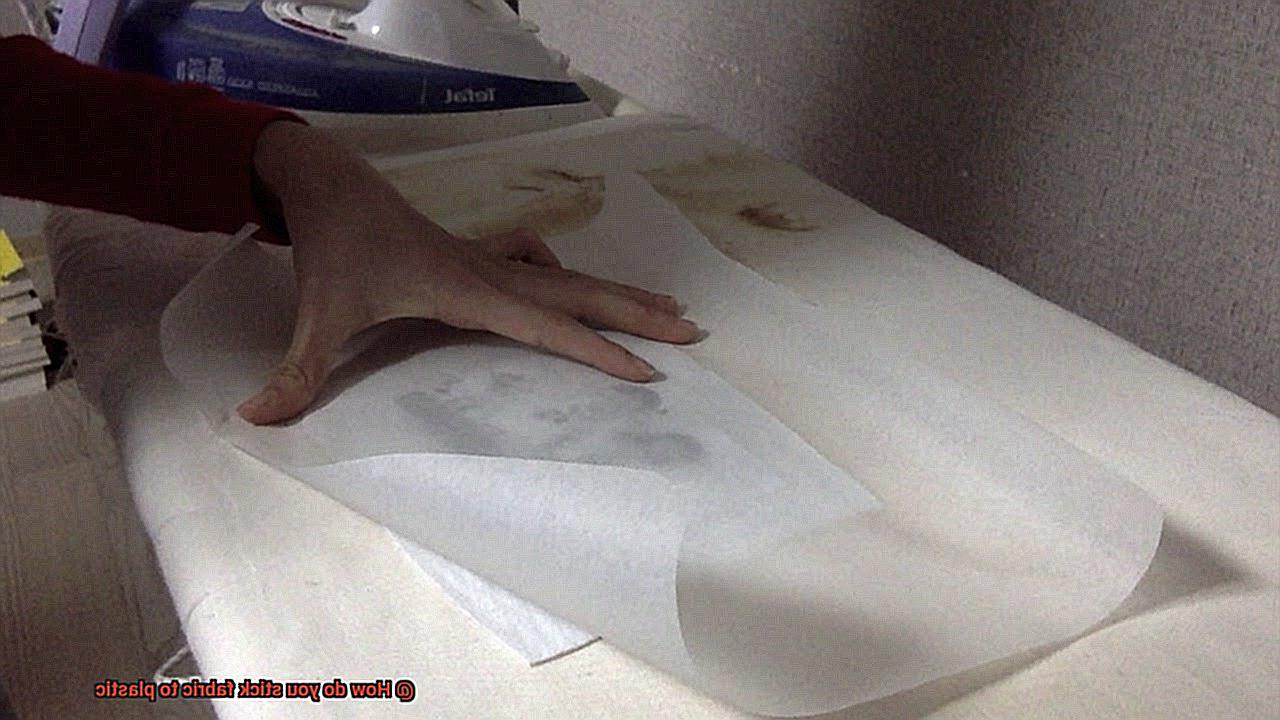

To activate the adhesive, the magic of heat presses or irons comes into play. By applying these instruments to the fabric and plastic surfaces, a symphony of heat and pressure ensues, causing the adhesive to melt and fuse the two materials together. This dynamic duo ensures an unyielding bond that can withstand even the harshest conditions.

Heat bonding works wonders for fabrics that cannot be sewn or may be weakened by traditional stitching methods. Delicate fabrics with intricate designs find solace in this technique, as it affords them a clean and professional finish without any visible traces of needlework on either the fabric or plastic surface.

Selecting the right heat activated adhesive is paramount for achieving a strong bond. Each adhesive boasts unique strengths and properties, necessitating careful consideration to find the perfect match for your specific fabric and plastic combination. Additionally, certain adhesives are tailored to bond specific types of fabrics or plastics, further emphasizing the importance of compatibility.

Embracing heat bonding allows for unparalleled flexibility in design and application. This method enables you to bond fabrics of different shapes, sizes, and types to various plastics, unlocking a world of limitless creativity and innovation across multiple industries.

However, it is crucial to follow guidelines and instructions meticulously when utilizing heat activated adhesives for heat bonding. Failure to do so may result in weak bonds or damage to the materials, compromising the integrity of your work. Therefore, it is imperative to read and comprehend the instructions provided.

Sewing: Ideal for Heavy or Thick Fabrics

When it comes to heavy or thick fabrics, sewing is the ideal method for creating a strong and durable bond with plastic. Whether you’re working on a project that requires the two materials to be joined together or you simply want to experiment with different fabric and plastic combinations, sewing provides the perfect solution. Here’s why:

- Appropriate Needle and Thread: Sewing heavy or thick fabrics to plastic requires the use of specialized tools. Heavy-duty needles, such as denim or leather needles, are designed to penetrate tough materials without breaking or bending. This ensures that you can sew through the layers of thick fabric and plastic with ease. Additionally, using strong and durable threads like nylon or polyester will withstand the strain of sewing heavy fabrics to plastic, ensuring a long-lasting bond.

- Preparing the Materials: Before you start sewing, it’s essential to prepare both the fabric and plastic. Clean them thoroughly to remove any dust or debris that could interfere with the sewing process. This step is crucial for achieving smooth and precise stitches.

- Securing the Materials: To prevent any shifting or misalignment during sewing, use pins or clips to hold the fabric and plastic together securely. This will ensure that they stay in place and maintain their desired position throughout the stitching process.

- Stitch Length and Tension: Sewing heavy fabrics to plastic requires some adjustments in stitch length. Opt for a longer stitch length to accommodate the thickness of the materials and prevent puckering or bunching. Additionally, adjusting the tension on your sewing machine will help ensure smooth stitching through both layers.

- Sew Slowly and Carefully: Heavy or thick fabrics can put strain on your machine’s motor if sewn too quickly. It’s important to take your time and sew slowly and carefully. By doing so, you’ll achieve better results and avoid potential damage or frustration.

- Finishing Touches: Once you’ve finished sewing, give your project a clean and professional finish by trimming any excess fabric or thread. Secure the ends of the stitching with a few backstitches or knots to prevent unraveling and ensure longevity.

Conclusion

When it comes to sticking fabric to plastic, there are a few effective methods you can try. One option is using fabric glue specifically designed for bonding fabric to plastic surfaces. This adhesive is usually strong and durable, ensuring that the fabric stays securely attached.

Another method is using double-sided tape or adhesive sheets. These products have adhesive on both sides, allowing you to easily stick the fabric to the plastic surface. They are convenient and provide a temporary bond that can be easily removed if needed.

If you’re looking for a more permanent solution, consider using heat-activated adhesive films or fusible webbing. These materials require heat application, such as ironing, to bond the fabric and plastic together. They create a strong bond that withstands washing and regular use.

For small fabric pieces or embellishments, you can also use hot glue. This versatile adhesive works well on various surfaces, including plastic. Just be careful not to apply too much heat as it can damage certain types of fabrics.

In conclusion, sticking fabric to plastic doesn’t have to be a daunting task. With the right adhesive and technique, you can achieve a secure and long-lasting bond between these two materials.