Are you tired of your DIY projects falling apart when exposed to water? Do you need an adhesive that can withstand the elements? Look no further than water-resistant glue.

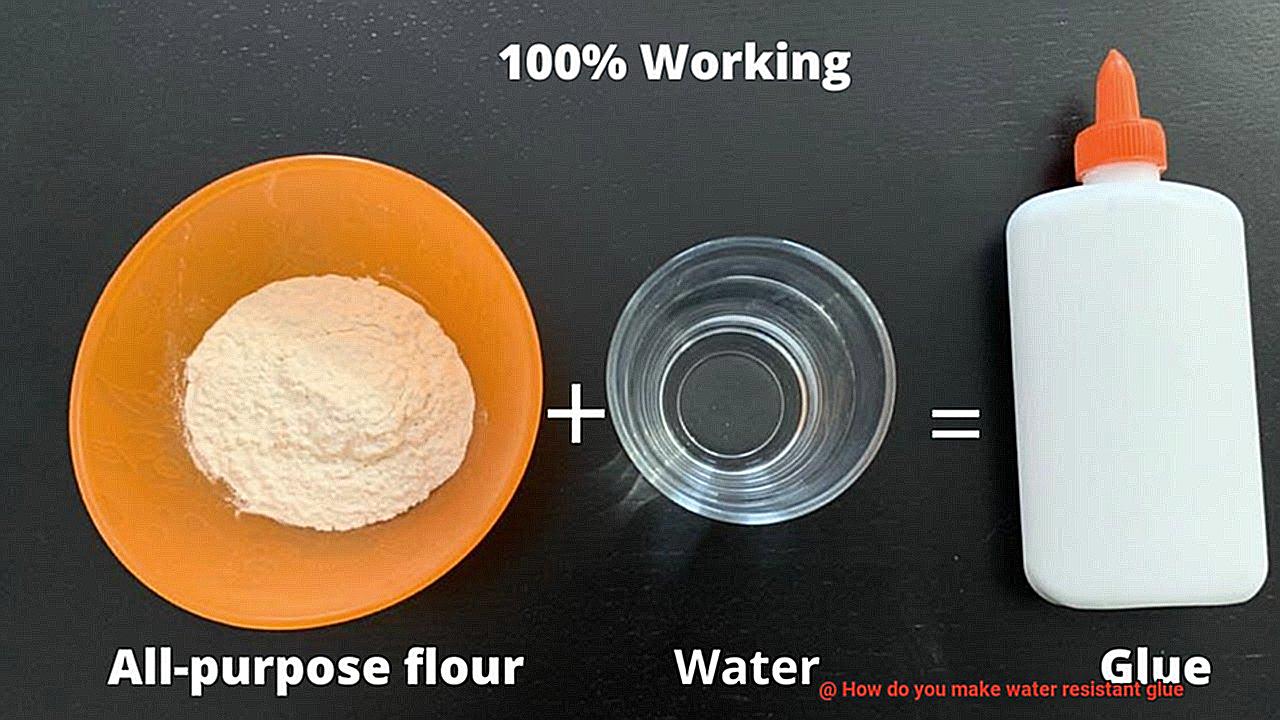

But how do you make it? Is it a complicated process involving obscure chemicals and equipment? Not at all. In fact, you only need three natural ingredients, which may already be sitting in your pantry.

In this post, we’ll explore the science behind water-resistant glue and explain why it’s such a game-changer for any project that requires durability. We’ll also guide you through the simple steps to make your own high-quality adhesive from scratch.

By the end of this post, you’ll have a newfound appreciation for natural adhesives and their superior performance compared to store-bought options. So let’s dive into the world of water-resistant glue and discover how easy it is to create a robust adhesive that can stand up to anything Mother Nature throws its way. Get ready to be amazed.

What is Water-Resistant Glue?

Contents

Water-resistant glue is a specialized adhesive designed to withstand exposure to water without losing its bonding properties. This type of glue is essential in various applications, including woodworking, construction, and even boat building.

One of the key features of water-resistant glue is its resistance to water. This means that it won’t break down or lose its bonding strength when exposed to moisture, making it an ideal choice for outdoor furniture or marine applications.

There are various types of water-resistant glue available on the market, each with its unique properties and characteristics. Polyurethane glue, for example, is a popular choice for outdoor applications because of its excellent resistance to water and ability to bond with a variety of materials, including wood, plastic, metal, and stone.

Epoxy glue is another popular option that can bond with ceramics and glass. Its ability to bond with a wide range of materials makes it an excellent choice for many applications that involve exposure to water.

Cyanoacrylate glue, also known as superglue, is a fast-drying adhesive that can bond to various surfaces, including plastics and metals. Although not specifically designed for water resistance, cyanoacrylate glue can still provide a strong bond even when exposed to moisture.

When selecting a water-resistant glue, it’s crucial to consider the specific application and desired level of water resistance needed. There are several methods for making water-resistant glue, including adding a waterproofing agent to a regular adhesive or using synthetic polymers like cyanoacrylate or epoxy.

For those who prefer natural materials, animal hide or fish bone glue can also be used to create water-resistant adhesives. These traditional glues have been used for centuries in woodworking and boat building.

Advantages of Water-Resistant Glue

Water-resistant glue has emerged as a revolutionary adhesive that can tackle even the toughest conditions. Its popularity has skyrocketed over the years, and for good reason. In this article, we will explore the advantages of using water-resistant glue and why it’s worth considering for your next project.

Advantage #1: Resilience Against Moisture and Humidity

Water-resistant glue is the perfect adhesive for applications where moisture is a concern. It’s an excellent option for woodworking, boatbuilding, outdoor construction, and any other project that may be exposed to water. Unlike traditional adhesives, water-resistant glue maintains its bonding strength, even when exposed to high levels of humidity or moisture.

Advantage #2: Unmatched Bonding Strength

One of the most significant advantages of water-resistant glue is its strength. It forms a bond stronger than traditional adhesives, making it ideal for more demanding applications. Whether you’re building furniture or constructing a house, water-resistant glue can get the job done.

Advantage #3: Flexibility at its Finest

Water-resistant glue is more flexible than other types of adhesives, ensuring its durability. This feature makes it an excellent choice for use on materials that may expand or contract due to changes in temperature or humidity. The flexibility of this type of glue ensures that your project remains strong even when subjected to different weather conditions.

Advantage #4: Longevity in Strength

Water-resistant glue is less likely to break down or deteriorate over time, making it a valuable investment for any project. This means that it can help prolong the life of your project or product, ensuring it remains structurally sound for many years. This can be especially important in applications where safety is a concern.

Methods for Making Water-Resistant Glue

As an expert in the methods for making water-resistant glue, let me share with you some of the different options available.

One popular method is using synthetic resins such as urea-formaldehyde, phenol-formaldehyde, and melamine-formaldehyde. These resins can be customized to achieve specific properties, such as faster curing time, higher strength, and resistance to temperature changes. This method offers unmatched strength and resilience against moisture and humidity, making it a versatile option for various applications.

Another method is adding fillers and additives to traditional adhesives like PVA and epoxy. Fillers such as silica or clay can improve the strength and adhesion of the glue while also reducing shrinkage and cracking. Additives like waxes or oils can improve flexibility and resistance to water. This method provides an easy way to upgrade your existing adhesives without having to switch to a completely new product.

For those looking for a natural and eco-friendly option, natural polymers may be the way to go. Animal hide glue has been used for centuries in woodworking due to its excellent water resistance. While plant starches such as cornstarch or potato starch can be modified to form a water-resistant adhesive by adding borax or other chemicals. Not only are these options sustainable, but they also offer unique properties that may be beneficial for certain projects.

Adding a Waterproofing Agent to Regular Adhesive

Adding a waterproofing agent to regular adhesive is a brilliant way to create water-resistant glue that can stand up to moisture and humidity. This simple process involves mixing the adhesive with a waterproofing agent to create a stronger bond that can withstand the elements.

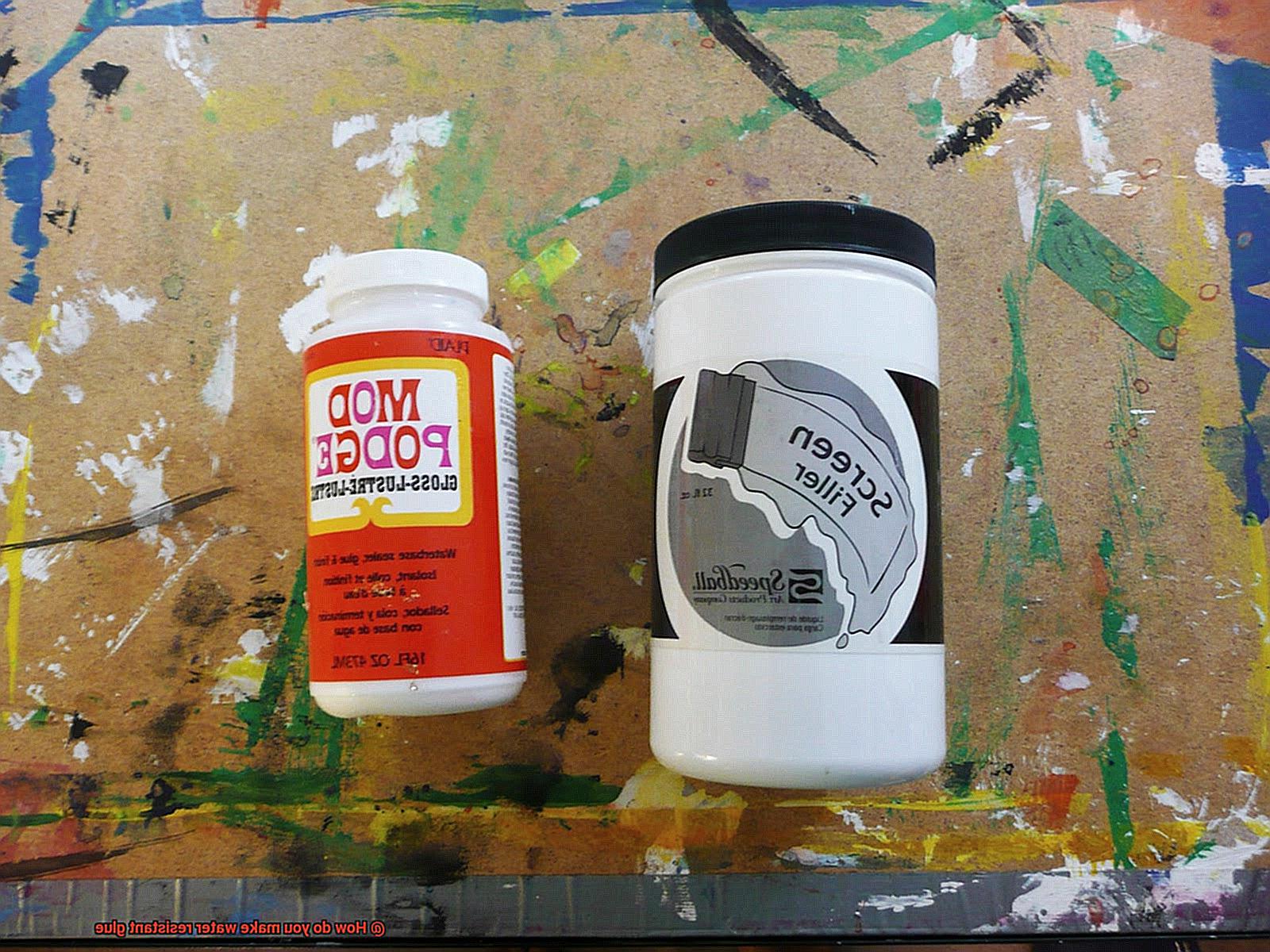

Silicone is one of the most popular waterproofing agents used to create water-resistant glue. Known for its water-repelling properties, silicone can be added to different types of adhesives like epoxy, polyurethane, and PVA glue. Another option is latex, which is commonly found in paint and can be added to wood glue and PVA glue.

To make water-resistant glue using silicone or latex, you will need to mix a small amount of the waterproofing agent with your adhesive until it forms a smooth and consistent mixture. The amount of waterproofing agent you add will depend on the type of adhesive and the level of water-resistance you want to achieve.

When adding a waterproofing agent to regular adhesive, it’s essential to follow the manufacturer’s instructions carefully. Adding too much or too little waterproofing agent can negatively affect the bond’s strength and durability. Therefore, it’s crucial to mix the adhesive with the waterproofing agent until it forms a uniform mixture without any clumps or inconsistencies.

Using Synthetic Polymers

Let’s explore the different types of synthetic polymers that are used in creating water-resistant glue.

First up is polyvinyl acetate (PVA), which is a popular choice for woodworking and carpentry projects. PVA glue is known for its strong bonding capability and resistance to water. The best part? It’s easy to use, dries clear, and can be sanded or painted over once it has dried.

Next on the list is polyurethane glue, which is known for its ability to create a strong bond even when exposed to water, heat, or chemicals. It’s often used in construction projects, particularly when bonding materials such as wood, metal, or plastic.

And finally, we have epoxy resin – a two-part adhesive that creates a strong bond that is resistant to water and chemicals. Epoxy glue is commonly used in marine applications such as boat building and repair.

When it comes to making water-resistant glue, choosing the right type of synthetic polymer is crucial. Each type offers unique advantages depending on the project and materials being bonded. Whether you’re a professional or DIY enthusiast, using synthetic polymers like PVA, polyurethane, or epoxy resin can help you create a bond that will last for years to come.

Using Natural Materials

Using natural materials to make water-resistant glue is a fantastic choice for those who are environmentally conscious. Not only do these natural glues produce a strong and durable adhesive, but they also have a lower carbon footprint than synthetic adhesives.

Let’s explore some of the various natural materials that can be used to create water-resistant glue. One of the most common natural materials used is animal hide or bone. Hide glue has been utilized for centuries in woodworking and musical instrument making. To make hide glue, animal hides or bones are boiled in water until they break down into a gelatinous substance. The glue dries quickly and forms a strong bond that is resistant to water.

Another natural material that can be used to make water-resistant glue is tree sap or resin. This type of glue has been used by indigenous cultures for thousands of years and is still used today in some traditional crafts. The resin is collected from trees and heated until it becomes a sticky liquid. The liquid is then mixed with other natural materials such as honey or beeswax to create a strong adhesive.

Egg whites, milk, and soy are additional natural materials that can be used to create water-resistant glue. Egg white glue is made by separating the egg white from the yolk and whisking it until it becomes frothy. The frothy mixture is then applied to surfaces and allowed to dry. Milk glue is made by mixing casein protein found in milk with an alkaline substance such as vinegar or baking soda. Soy glue is made by extracting protein from soybeans and mixing it with other natural materials to create an adhesive.

Using natural materials for your water-resistant glue not only produces a strong and durable adhesive but also reduces the environmental impact of using synthetic adhesives. Additionally, these natural glues are biodegradable, making them an eco-friendly choice for those who want to minimize their carbon footprint.

Choosing the Right Method

Choosing the right method for making water-resistant glue can make all the difference. As an expert in this field, I’m here to provide you with a comprehensive guide on the different methods and how to select the perfect one for your needs.

Firstly, synthetic resins such as epoxy or polyurethane are a popular choice for their water-resistant properties. These resins can be mixed with other materials to create a bond that will hold up even when exposed to moisture. These synthetic resins are ideal for bonding metal, glass, and ceramics, among other materials.

Secondly, adding a waterproofing agent like silicone or wax to the glue mixture creates a barrier that prevents water from penetrating the glue. However, it’s essential to use the correct amount of agents as too much can weaken the bond. These agents are perfect for bonding paper products, fabrics, and leather.

Lastly, combining both synthetic resins and waterproofing agents provides extra protection against water damage and ensures a strong bond that will last over time. This method is best suited for bonding wood products with other materials.

When selecting the appropriate method for making water-resistant glue, it’s crucial to consider the materials being bonded, the environment in which the glue will be used, and the level of water resistance needed. By doing so, you’ll be able to choose an appropriate method and ensure a strong and durable bond that will hold up even in wet conditions.

If you’re looking for eco-friendly options, natural water-resistant glue made from animal hides, tree sap or resin, egg whites, milk or soy is also available. These glues are biodegradable and have a lower carbon footprint than synthetic counterparts.

DIY Tips for Making Water-Resistant Glue

There are several methods and ingredients you can use to make water-resistant glue, and they are relatively easy and affordable.

Method 1: Vinegar and Glue

One method involves mixing equal parts of white glue and white vinegar. The vinegar acts as a mild acid that can help strengthen the bond and make it more resistant to water. Simply mix the two ingredients together in a bowl or container, stirring well until the mixture is smooth and consistent. Apply the glue to the surfaces you want to bond, press them together firmly, and let the glue dry completely. This type of water-resistant glue works well for porous materials like paper, cardboard, fabric, and more.

Method 2: Silicone Sealant and Glue

Another method involves adding a few drops of silicone sealant or caulk to your regular glue. Silicone is a type of synthetic rubber that is highly resistant to water and heat, making it ideal for creating strong and flexible bonds that can withstand harsh conditions. To make this type of water-resistant glue, simply squeeze a small amount of regular glue onto a clean surface, add a few drops of silicone sealant or caulk, and mix them together thoroughly with a toothpick or small stick. Apply the glue to the surfaces you want to bond, press them together firmly, and let the glue dry completely. This type of water-resistant glue works well for non-porous materials like plastic, metal, glass, and more.

Method 3: Gelatin or Agar-Agar

For a natural option, try using gelatin or agar-agar to make water-resistant glue. Gelatin is derived from animal collagen, while agar-agar comes from seaweed. Both substances are soluble in hot water but become insoluble when cooled, forming a gel-like substance that can create strong bonds between surfaces. To make this type of water-resistant glue, mix a small amount of gelatin or agar-agar with hot water, stirring well until the mixture is smooth and consistent. Apply the glue to the surfaces you want to bond, press them together firmly, and let the glue cool and solidify. This type of water-resistant glue works well for natural materials like wood, leather, and more.

It’s important to note that making water-resistant glue requires precise measurements and mixing techniques. Be sure to follow the instructions carefully and use the right amount of each ingredient for the best results. Additionally, when applying water-resistant glue, it’s crucial to prepare the surface properly. The surface should be clean, dry, and free of any debris or dust that may affect the bond strength. It is also recommended to apply pressure on the glued surfaces for a few minutes to ensure a strong bond.

qkurz6sEuRU” >

Also Read: Is Super Glue Waterproof? – Glue Things

Conclusion

In conclusion, water-resistant glue is a game-changer for any project that requires durability and can withstand exposure to water without losing its bonding properties. The benefits of using water-resistant glue are manifold, including resilience against moisture and humidity, unmatched bonding strength, flexibility, and longevity in strength. Fortunately, there are various methods for making water-resistant glue that suit different needs.

One way to make water-resistant glue is by adding a waterproofing agent to regular adhesive or using synthetic polymers like polyvinyl acetate (PVA), polyurethane glue, or epoxy resin. Another option is to use natural materials such as animal hide or bone glue, tree sap or resin, egg whites, milk, or soy to create water-resistant adhesives.

When choosing the appropriate method for making water-resistant glue at home, it’s essential to consider the materials being bonded and the environment in which the glue will be used. DIY tips include mixing equal parts white glue and vinegar or adding silicone sealant or caulk to regular glue.

In summary, creating your own high-quality adhesive from scratch that can stand up to anything Mother Nature throws its way is easier than you might think. With just a few natural ingredients that may already be sitting in your pantry and some simple steps to follow, you can enjoy the benefits of natural adhesives over store-bought options.