Are you in a rush to glue something together but don’t want to compromise on strength and durability? Enter epoxy glue, the superhero of adhesives that promises a strong bond and quick drying time. But what if you need it to dry even faster? Fear not, dear reader, for we have got you covered.

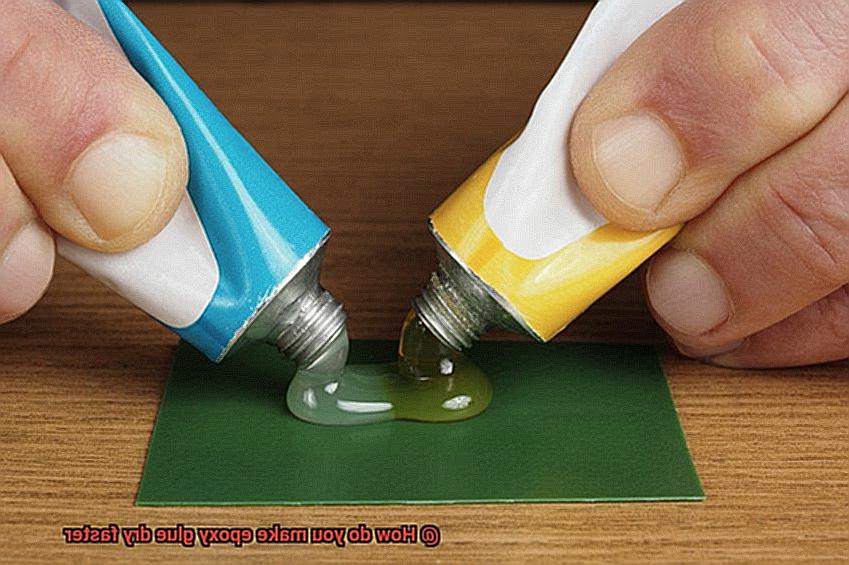

Epoxy glue consists of a resin and hardener that combine to create a chemical reaction, resulting in a solid bond. Adjusting the ratio of resin to hardener can affect the drying time, but sometimes that’s just not enough. So what can you do?

There are several methods to expedite the drying process of epoxy glue. From raising the temperature to using accelerators, we will explore them all. However, it’s crucial to understand that some methods may impact the strength of the bond, so proceed with caution.

In this post, we’ll delve into the various techniques for making epoxy glue dry faster and provide some handy tips for achieving optimal results. So buckle up and get ready for a speedy ride.

What is the Curing Time for Epoxy Glue?

Contents

Epoxy glue is a popular adhesive that is well known for its exceptional bonding capabilities. However, one of the downsides of using epoxy glue is its relatively long curing time. Curing time refers to the time it takes for the adhesive to fully dry and harden, and it can vary depending on several factors such as the type of epoxy, temperature, humidity, and thickness of the application.

Patience is key when using epoxy glue because it typically takes around 24-48 hours for most types of epoxy glue to cure completely. Some types of epoxy glues may even take up to a week or more to fully cure. It is essential to wait until the curing time has passed before subjecting the bond to any stress or load. While the adhesive may feel dry to the touch after a few hours, it may not have fully cured yet.

To ensure that the epoxy glue cures appropriately and within the expected timeframe, it is crucial to follow the manufacturer’s instructions carefully. This includes mixing the two parts of the adhesive in the correct ratio and applying it at the recommended thickness. Temperature and humidity also play a critical role in the curing time of epoxy glue. Higher temperatures can accelerate the curing process, while colder temperatures can slow it down.

If you need a faster drying time for your epoxy glue, there are several methods that you can try to speed up the process. One way is by applying heat to the adhesive using a heat gun or hairdryer; this method increases the temperature of the adhesive, which causes it to cure more quickly. Another method is by adding a catalyst or accelerator to the epoxy glue mixture. These substances promote faster curing times by increasing the chemical reaction between the resin and hardener.

It is important to remember that these methods may affect the strength and durability of the bond if not used correctly. Therefore, following the manufacturer’s instructions carefully and testing the adhesive before using it in high-stress applications is crucial. Additionally, reducing the humidity in your workspace when working with epoxy glue can also help to create a drier environment that promotes faster drying times.

Applying Heat to Speed Up Drying Time

Applying heat can speed up the drying process and get your project done in no time.

The science behind applying heat to epoxy glue is simple. Heat causes the molecules in the glue to move faster, which in turn accelerates the chemical reaction that causes the glue to harden. There are several ways to apply heat to your epoxy glue to make it dry faster.

Firstly, using a heat lamp is one of the easiest methods for applying heat. The infrared radiation emitted by the heat lamp penetrates the surface of the glue and heats it up from the inside out. This method is particularly effective for large areas of epoxy glue, such as on a tabletop or countertop.

Secondly, a hair dryer or heat gun can be used to blow hot air onto the surface of the glue. This helps to evaporate any moisture and speed up the drying process. However, caution must be taken as too much heat can cause the glue to bubble or burn.

Thirdly, using a curing oven is an ideal option for large or complex projects where precise temperature control is important. These ovens are specifically designed for curing epoxy and other types of adhesives, providing consistent and controlled heat for an extended period of time.

It’s important to note that applying too much heat can affect the strength and durability of the cured epoxy glue. Therefore, it’s essential to consult with a professional or follow the manufacturer’s instructions carefully.

Using a Catalyst or Accelerator

These products are like little helpers that can make all the difference in your DIY project.

Catalysts are substances that increase the rate of a chemical reaction without being consumed in the process. When it comes to epoxy glue, diethylenetriamine (DETA) is a popular choice for a catalyst. This colorless liquid with a strong odor helps initiate the curing process and allows the glue to dry faster. By adding a catalyst, you can significantly reduce the waiting time for your epoxy glue to dry.

Accelerators, on the other hand, provide heat energy that speeds up the chemical reaction between the resin and hardener. Benzyl alcohol and triethanolamine are commonly used accelerators in epoxy glues. With the help of an accelerator, you can boost the rate of the chemical reaction, leading to faster drying times.

But be careful. Adding too much catalyst or accelerator can cause the glue to dry too quickly, making it difficult to apply and manipulate. It’s crucial to follow the manufacturer’s instructions carefully and use these products in moderation. By doing so, you can achieve optimal results without compromising the integrity of your project.

Reducing Humidity in Workspace for Faster Drying Times

High humidity can significantly slow down the curing process of epoxy adhesive, leading to longer drying times and weaker bonds. But don’t worry – there are a few simple steps you can take to manage humidity levels and promote optimal curing conditions for your epoxy glue.

Firstly, consider using a dehumidifier in your workspace. By removing excess moisture from the air, a dehumidifier creates a dry environment that accelerates epoxy curing times. You can place the dehumidifier near your work area or use multiple units to cover a larger space.

In addition to using a dehumidifier, improving ventilation is another effective way to reduce humidity in your workspace. Proper ventilation helps to circulate the air and remove excess moisture, creating a drier environment that promotes faster epoxy curing times. You can open windows or doors to improve airflow or use fans to increase air circulation.

However, even with a dehumidifier and proper ventilation, it’s important to keep your workspace clean and free of any moisture sources. Moisture can come from various sources, such as leaking pipes, wet floors, or damp walls. By identifying and fixing any moisture sources, you can prevent excess moisture from building up in your workspace and reduce the risk of slower epoxy drying times.

Pros and Cons of Using Heat and Catalysts

Speeding up the process with heat or catalysts may sound like a tempting solution, but it’s important to weigh the pros and cons of each method before diving in.

Let’s start with using heat. This method involves applying heat to the glued area using a heat gun or hair dryer. The advantage of using heat is that it can be a quick and easy method to speed up the drying process, while also improving the strength and durability of the bond between surfaces. However, excessive heat can lead to bubbling or boiling of the glue, which can weaken the bond and affect the overall quality of the finished product. Moreover, certain materials may become discolored or damaged with too much heat exposure.

On the other hand, adding a catalyst to the glue mixture can also speed up the chemical reaction between the resin and hardener, resulting in a faster curing time. This method is often preferred for larger projects or thicker layers of glue. A great advantage of using a catalyst is that it does not require any additional tools or equipment like heat does and can produce a stronger and more durable bond between surfaces. However, adding too much catalyst can cause the glue to become brittle and less durable. Additionally, some types of catalysts may have certain health risks associated with them.

So which method should you choose? It really depends on your specific project and materials. If you’re working with delicate materials or don’t have access to a heat gun or hair dryer, then using a catalyst may be your best option. On the other hand, if you’re working with more durable materials and have some experience with applying heat, then using heat may be a quick and easy solution.

Testing the Adhesive Before Use

When it comes to using epoxy glue, testing the adhesive before use is an essential step that can make or break your project. Not only can this save you from potential accidents or damage caused by weak bonds, but it can also ensure that your project will hold up over time. Here are some steps you can follow to test epoxy glue before use.

Step 1: Clean and Dry Surfaces

Before starting, make sure that the surfaces you’re planning to bond together are clean and dry. Any dirt, grease, or moisture can weaken the bond, so be sure to clean them thoroughly.

Step 2: Apply Epoxy Glue and Press Surfaces Together

Once the surfaces are clean and dry, apply a small amount of epoxy glue onto one of the surfaces following the manufacturer’s instructions for mixing the glue if necessary. Then, press the two surfaces together firmly.

Step 3: Allow Adhesive to Cure

After pressing the surfaces together, allow the adhesive to cure according to the manufacturer’s instructions. This usually takes a few hours to overnight, and it’s important to avoid moving or disturbing the bonded surfaces during this time.

Step 4: Test Bond Strength

Once the curing time has elapsed, it’s time to test the bond strength. Attempt to pull the two surfaces apart with moderate pressure. If the bond holds up and is strong, then you’re good to go. However, if the bond is weak or comes apart easily, then it may be necessary to choose a different type of adhesive or surface preparation method.

Tips for Working with Epoxy Glue

Working with epoxy glue can be a bit tricky, but by following some simple tips, you can ensure that it dries properly and efficiently. Here are five sub-sections to consider when working with epoxy glue:

Mixing Properly

Epoxy glue is a two-part adhesive that needs to be mixed thoroughly before use. It is essential to follow the instructions on the packaging and mix the two parts together in the correct proportions. A proper mix will ensure that the adhesive cures properly and dries faster.

Applying Thin Layers

Thick layers take longer to cure, so it’s better to apply several thin coats rather than one thick coat. Applying thin layers of epoxy glue can reduce drying time significantly. It also ensures that the adhesive adheres properly and minimizes any potential air bubbles.

Using a Heat Source

Applying heat to the epoxy glue can help speed up the drying process. You can use a heat gun or a hairdryer on a low setting to gently heat the surface of the adhesive, which will help it cure faster. However, be careful not to overheat the surface, as this can cause cracks or bubbles.

Reducing Humidity

High levels of humidity can slow down the curing process of epoxy glue. It is important to work in a warm and dry environment, as humidity and low temperatures can slow down the curing process. Ideally, the temperature should be around 70 degrees Fahrenheit or higher for maximum effectiveness.

Following Manufacturer’s Instructions

Always follow the manufacturer’s instructions when working with epoxy glue. This will ensure that you are using the product correctly and safely. Some types of epoxy glues are not compatible with accelerators, so make sure to check the manufacturer’s instructions before using them.

pTiEXiClFdk” >

Conclusion

In conclusion, epoxy glue is a remarkable adhesive that boasts of exceptional strength and durability. However, its curing time may not always align with your project’s timeline. Fortunately, there are several methods to expedite the drying process of epoxy glue, such as the use of heat or catalysts.

Applying heat to the adhesive can accelerate the drying process by causing the molecules in the glue to move faster. Adding a catalyst or accelerator to the mixture can also promote faster curing times by increasing the chemical reaction between the resin and hardener.

It is essential to note that these methods may affect the bond’s strength and durability if not used correctly. Therefore, it is crucial to follow the manufacturer’s instructions carefully and test the adhesive before using it in high-stress applications.

Additionally, reducing humidity levels in your workspace when working with epoxy glue can help create a drier environment that promotes faster drying times. It would be best to mix properly, apply thin layers, use a heat source where necessary, reduce humidity levels and follow manufacturer’s instructions for optimal results.

Remember that patience is key when working with epoxy glue because it typically takes around 24-48 hours for most types of epoxy glue to cure completely.